Network group control-type error dynamic compensation system of numerically-controlled machine tools

A technology of CNC machine tools and compensation systems, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problems that cannot be implemented, and the writing methods of external zero offset bits are very different, so as to suppress the hysteresis effect of compensation , Execution speed is fast, and the effect of saving hardware cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

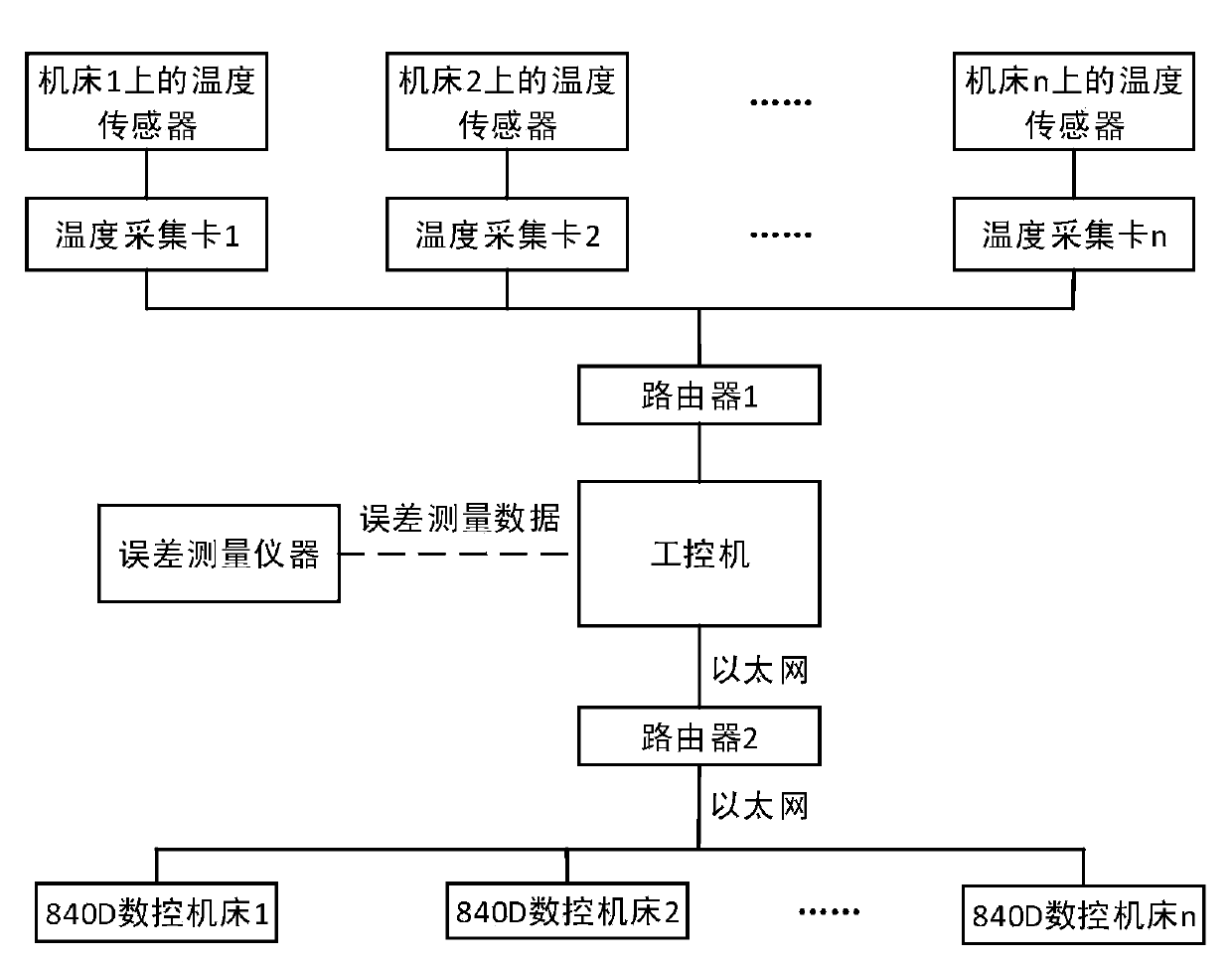

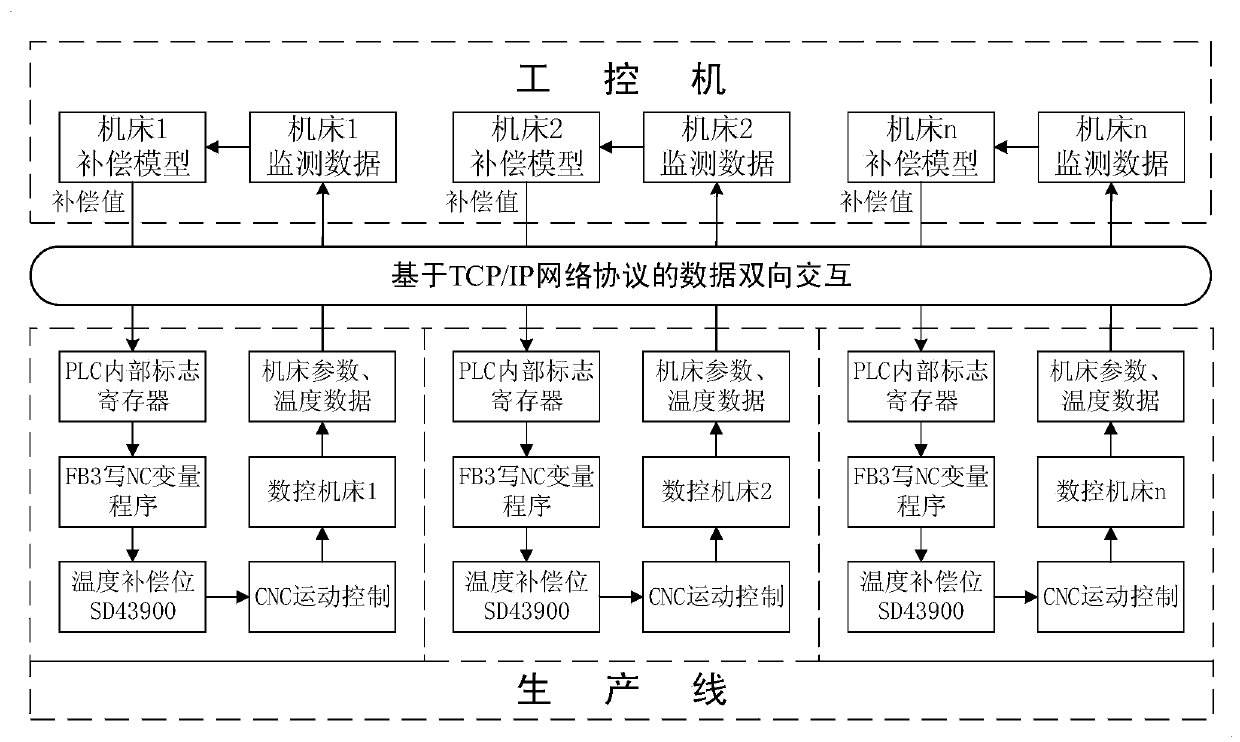

[0032] Such as figure 1 As shown, the network group control type error dynamic compensation system of the CNC machine tool of the present invention includes a machine tool error measuring instrument, multiple temperature sensors, multiple temperature data acquisition cards, multiple Siemens 840D CNC machine tools, 2 routers, 1 industrial computer, There are multiple network cables, the temperature sensor is connected to the temperature data acquisition card, and the multiple temperature acquisition cards are connected to the router 1 through the network cable, and the router 1 is connected to the industrial computer through the network cable; the machine tools integrated with the Siemens 840D numerical control system have built-in Ethernet ports, through The network cable connects multiple CNC machine tools to the router 2, and the router 2 is connected to the industrial computer through the network cable.

[0033] The machine tool error measuring instrument refers to the equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com