Interference Microscope Objective Optical System

An interference microscope and optical system technology, applied in the field of interference microscope objective optical system, can solve the problems of small interference microscope working distance, unstable interference fringes, inconvenient use, etc., and achieve small distortion, close imaging quality, and long working time effect of distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawings and examples, but the protection scope of the present invention should not be limited thereby.

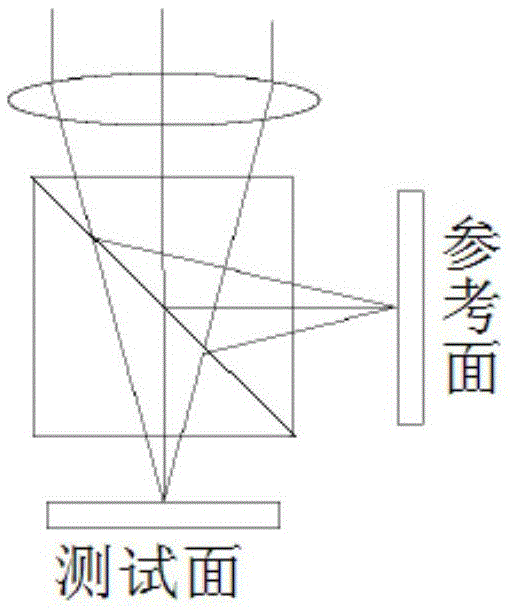

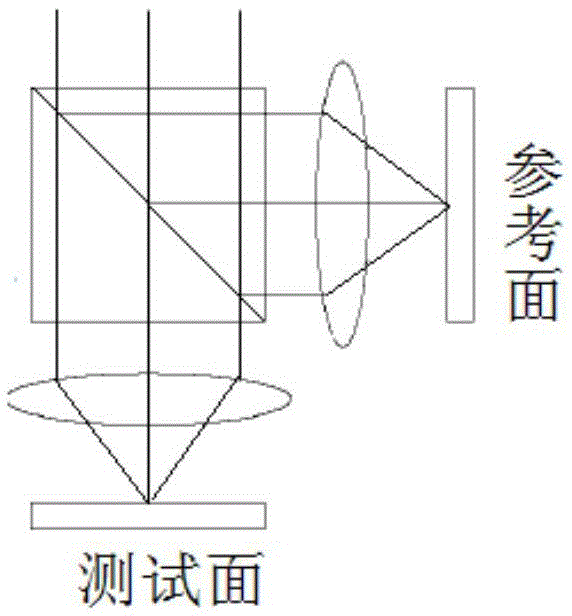

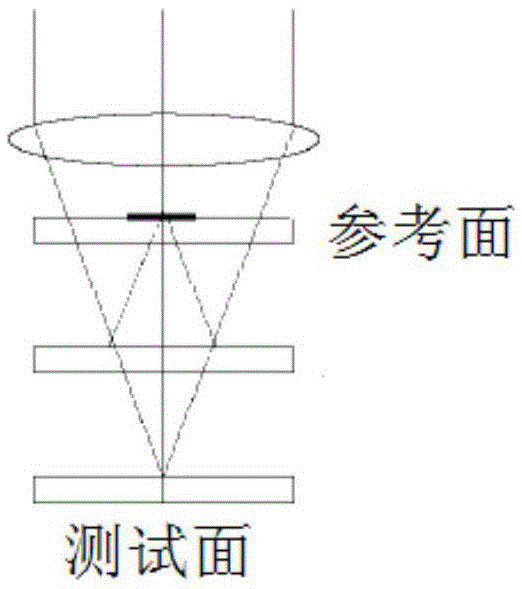

[0026] see figure 2 , the present invention is used in an interference microscope objective optical system, including a first lens group S1, a second lens group S2, a third lens group S3, a fourth lens group S4, an aperture stop U1, a fifth lens S5, and a sixth lens S6, the reference surface substrate group S7, and the beam-splitting platelet group S8 are sequentially arranged along the optical axis from left to right, and the first lens group to the beam-splitting platelet group constitute the objective lens group E1 of the system. The focal length of the second lens group S2 is fS2, the focal length of the third lens group S3 is fS3, and the focal length of the objective lens group is fE1, and the three satisfy the following relationship:

[0027] 1.2<|fS3 / fS2|<1.8,

[0028] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com