A simulation test bench for thermal shock and thermal fatigue of heated parts

A technology for simulating test benches and thermal shocks, applied in the field of simulating test benches, can solve problems such as late start, and achieve the effects of improving accuracy, saving test costs, and shortening research and development cycles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

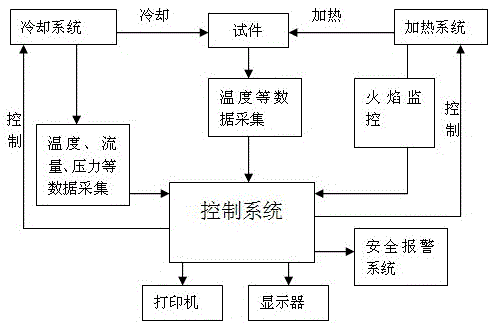

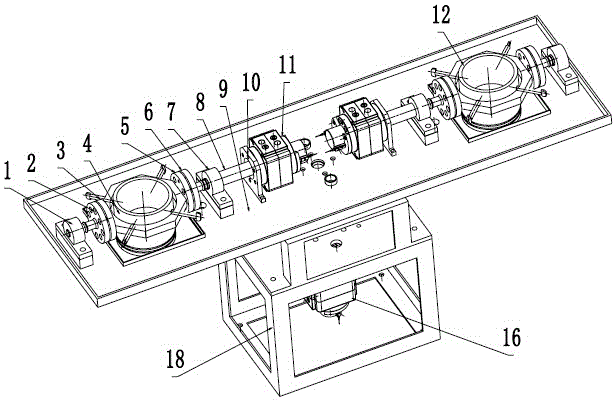

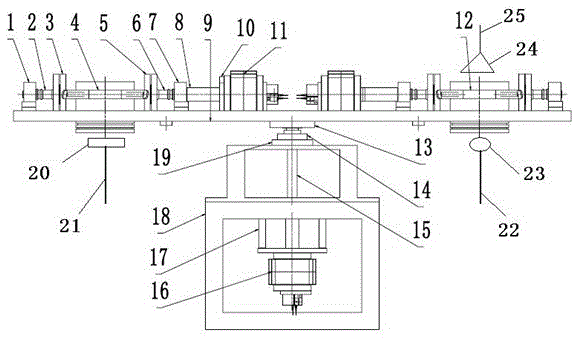

[0035] Embodiment 1: as Figure 1-6 As shown, a simulation test bench for thermal shock and thermal fatigue of heated parts includes a mechanical platform, a heating system, a cooling system, a temperature detection device, a control system, and a safety alarm device; the mechanical platform includes two sets of clamping devices, Heat insulation flange Ⅲ13, bearing with seat 14, main shaft 15, main shaft oscillating cylinder 16, main shaft oscillating cylinder bracket 17, support 18, bearing support 19, the two sets of clamping devices have the same structure and are installed symmetrically about the main shaft 15, and one set of clamping devices The tightening device includes ball bearing with seat Ⅰ1, left shaft 2, heat insulation flange Ⅰ3, clamping mechanism Ⅰ4, heat insulation flange Ⅱ5, right shaft 6, ball bearing with seat Ⅱ7, coupling 8, working platform 9, cylinder Support 10, swing cylinder 11; the ball bearing with seat Ⅰ1 is an interference fit with the left shaft ...

Embodiment 2

[0036] Embodiment 2: as Figure 1-6 As shown, a simulation test bench for thermal shock and thermal fatigue of heated parts includes a mechanical platform, a heating system, a cooling system, a temperature detection device, a control system, and a safety alarm device; the mechanical platform includes two sets of clamping devices, Heat insulation flange Ⅲ13, bearing with seat 14, main shaft 15, main shaft oscillating cylinder 16, main shaft oscillating cylinder bracket 17, support 18, bearing support 19, the two sets of clamping devices have the same structure and are installed symmetrically about the main shaft 15, and one set of clamping devices The tightening device includes ball bearing with seat Ⅰ1, left shaft 2, heat insulation flange Ⅰ3, clamping mechanism Ⅰ4, heat insulation flange Ⅱ5, right shaft 6, ball bearing with seat Ⅱ7, coupling 8, working platform 9, cylinder Support 10, swing cylinder 11; the ball bearing with seat Ⅰ1 is an interference fit with the left shaft ...

Embodiment 3

[0038] Embodiment 3: as Figure 1-6As shown, a simulation test bench for thermal shock and thermal fatigue of heated parts includes a mechanical platform, a heating system, a cooling system, a temperature detection device, a control system, and a safety alarm device; the mechanical platform includes two sets of clamping devices, Heat insulation flange Ⅲ13, bearing with seat 14, main shaft 15, main shaft oscillating cylinder 16, main shaft oscillating cylinder bracket 17, support 18, bearing support 19, the two sets of clamping devices have the same structure and are installed symmetrically about the main shaft 15, and one set of clamping devices The tightening device includes ball bearing with seat Ⅰ1, left shaft 2, heat insulation flange Ⅰ3, clamping mechanism Ⅰ4, heat insulation flange Ⅱ5, right shaft 6, ball bearing with seat Ⅱ7, coupling 8, working platform 9, cylinder Support 10, swing cylinder 11; the ball bearing with seat Ⅰ1 is an interference fit with the left shaft 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com