Remedying and reinforcing method for precast hollow driven piles

A hollow, pile foundation technology, applied in sheet pile wall, foundation structure engineering, foundation structure repair and other directions, can solve the problem that the bearing capacity or settlement of the foundation cannot reach the control standard, cannot be driven to the designed penetration position, and cannot use defective piles. and other problems, to achieve the effect of good engineering practical value, easy rotary spray pile construction, and easy construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

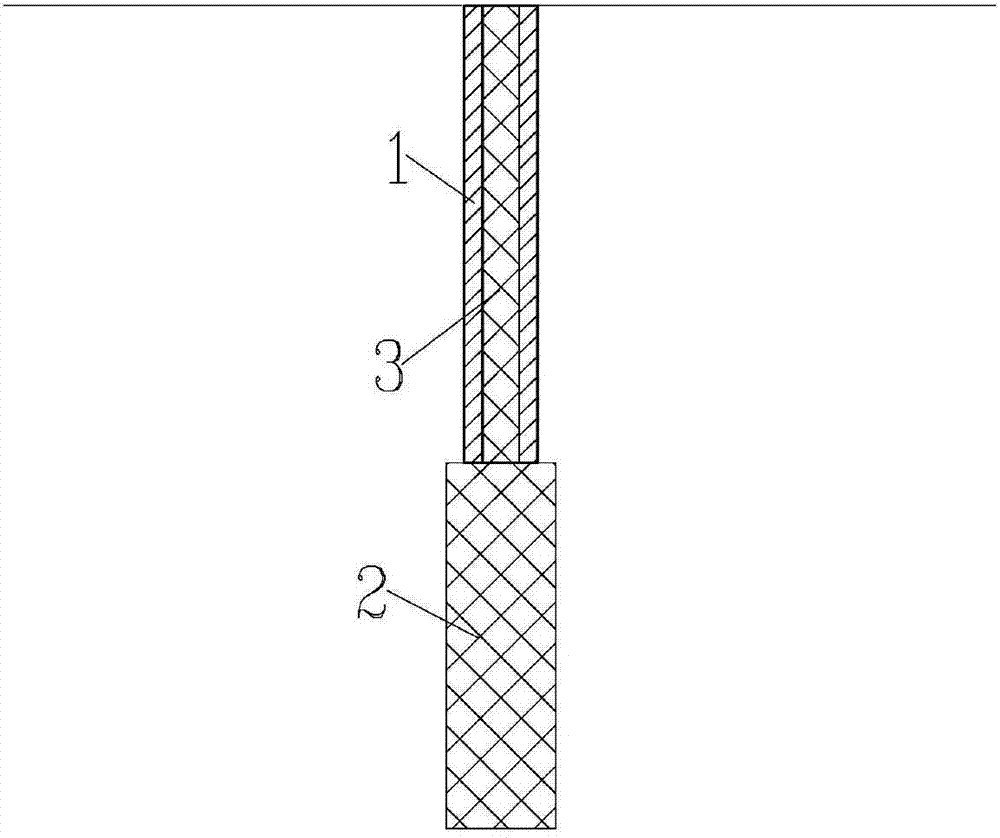

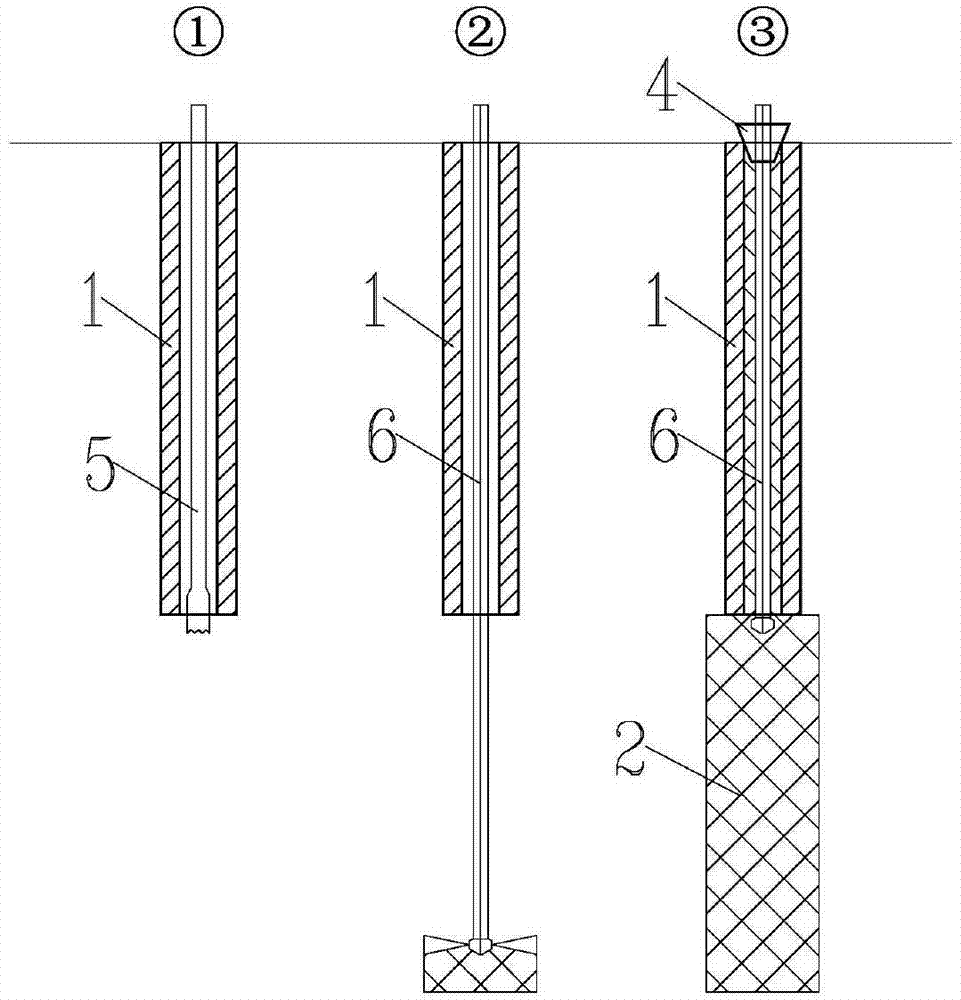

[0016] Embodiment: The prefabricated hollow driven pile foundation remedial reinforcement method according to the present invention comprises the following steps: figure 1 and figure 2 As shown, using the hollow of the existing driven pile, the drill pipe 5 of the jet grouted pile 2 passes through the hollow to the pile bottom of the defective driven pile, and the bottom of the pile is reinforced to the predetermined depth range to form the jet grouted pile 2. reinforcement. The rotary grouting pile 2 can be carried out by using single-pipe method, double-pipe method or three-pipe method according to geological conditions. The diameter of the rotary grouting pile 2 should be about 1.2 to 1.5 times the diameter of the prefabricated hollow driven pile 1. When the rotary grouting pile 2 is constructed to the bottom of the prefabricated driven pile, the grout stopper 4 is used to block the hollow part of the top of the prefabricated driven pile, and the grout stopper 4 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com