Method for evaluating roadbed grouting reinforcement effects

An evaluation method and grouting reinforcement technology, which can be applied in basic structure engineering, basic structure testing, construction, etc., can solve the problems of high cost, inability to evaluate the strength of subgrade, and low detection efficiency, and achieve the effect of avoiding engineering losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

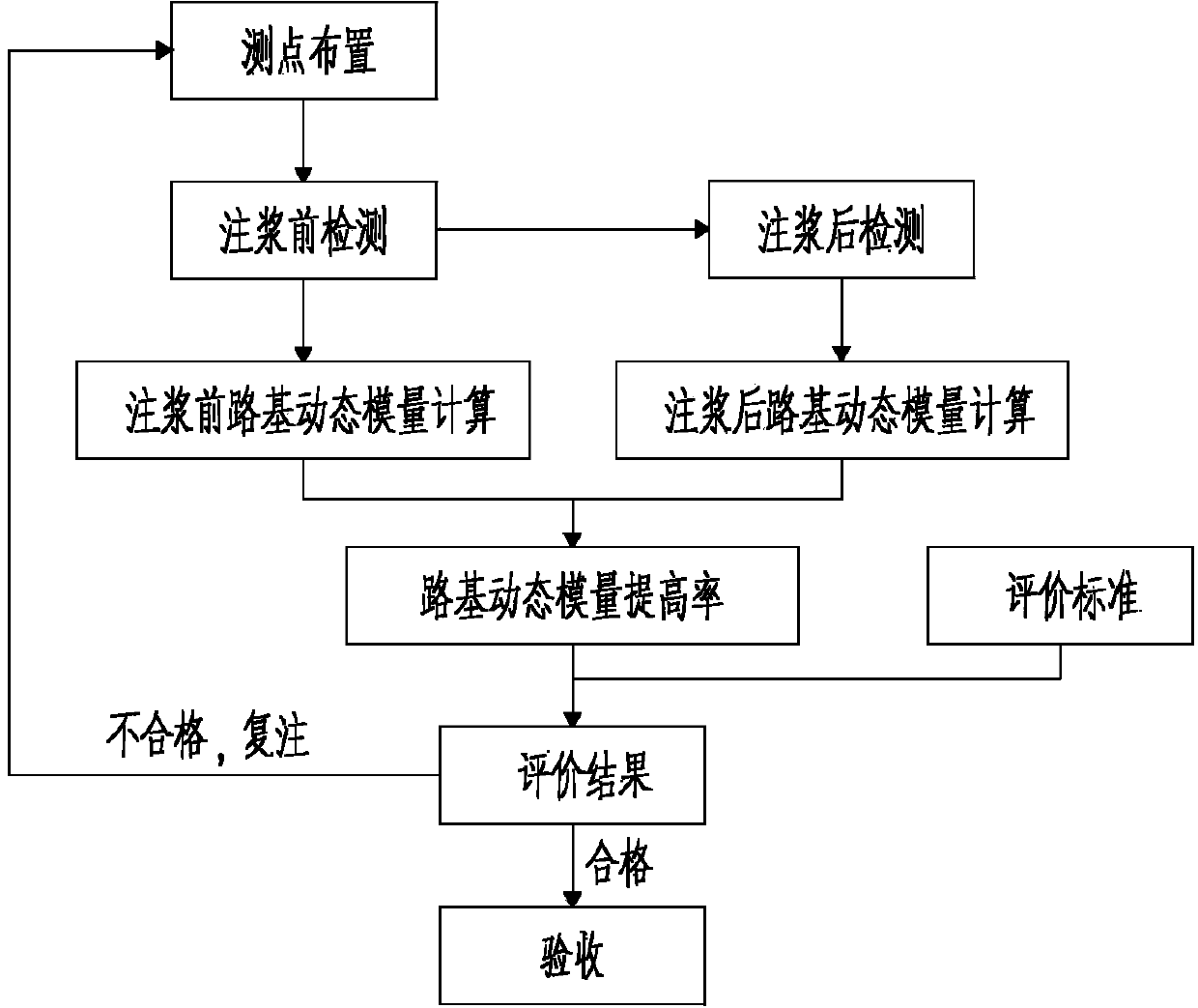

[0032] A method for evaluating roadbed grouting reinforcement effect, the steps of the evaluation method are:

[0033] ⑴. Measuring point layout: On the selected evaluation unit, select a point every 25m along the center line of the two rows of grouting holes as the detection position, and mark the detection position with paint;

[0034] ⑵. Dynamic elastic modulus test of subgrade before grouting:

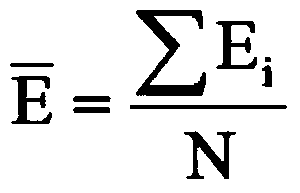

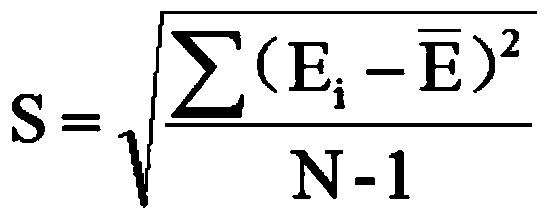

[0035] The drop weight deflection meter is used to test the above detection positions, and the dynamic elastic modulus E of the subgrade before grouting at each detection position is measured and calculated. i注浆前 ;

[0036] The steps are:

[0037] The drop weight deflection tester adopts 50kN±2.5kN impact load, and the diameter of the bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com