Embedded short strut structure and construction method thereof

A construction method, the technology of short-leg columns, applied in the direction of foundation structure engineering, columns, pier columns, etc., can solve the problems of affecting the construction period, slow construction, unfavorable cost saving, etc., and achieve the effect of cost saving and shortest construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

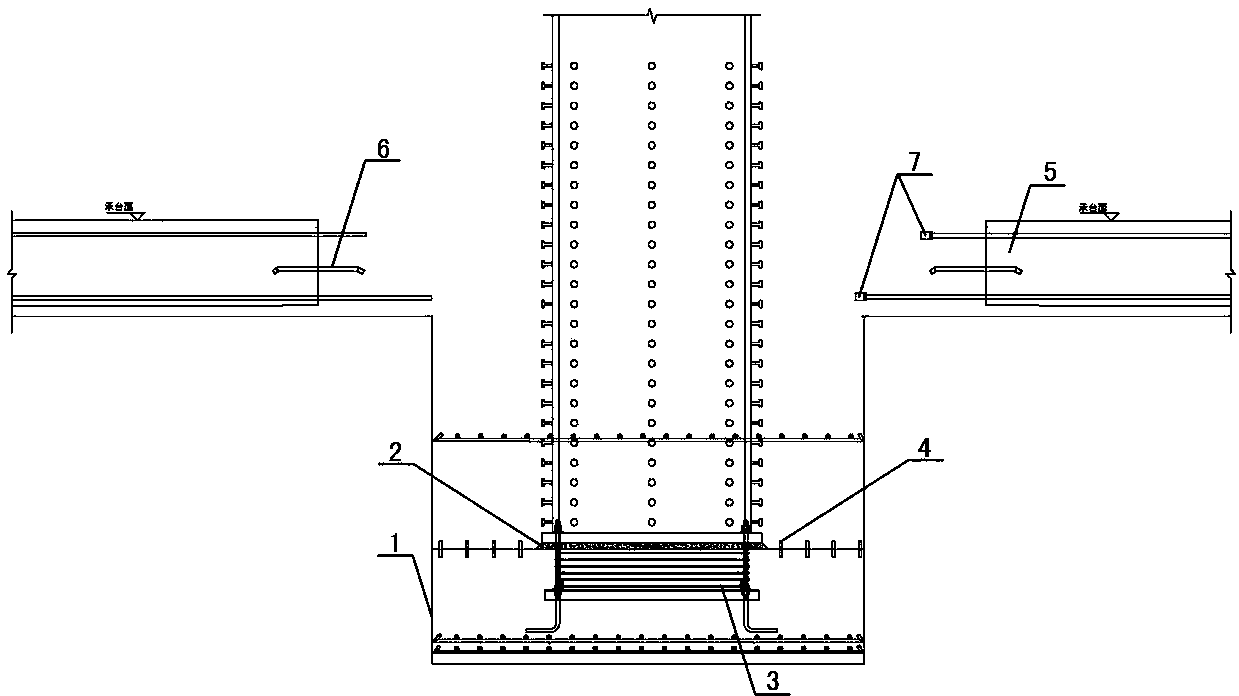

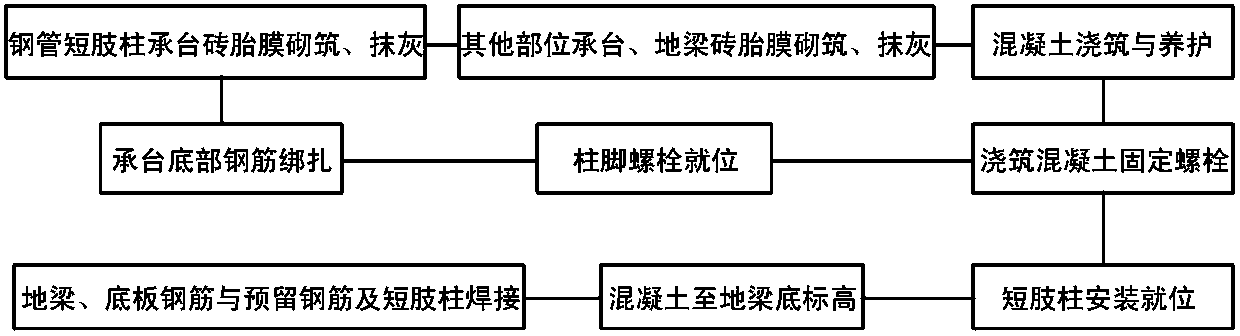

[0024] Below in conjunction with specific implementation case, the present invention is specifically described as follows: As a kind of pre-embedded short limb column structure of an embodiment of the present invention, as figure 1 As shown, the position of the short leg column is reserved around 1 / 3 of the span of the area where the steel pipe column is located. Except for the position of the reserved short leg column, the other base plates meet the design requirements. The lower end of the short leg column is provided with fixed angle steel. Set grouting surface shear reinforcement in between, set embedded bolts around the short column, reserve reinforcement at the disconnected position of the ground beam or slab, and set water-stop steel plate, set sleeve on one side of the reserved reinforcement, and use straight thread connection, and the other One side is welded.

[0025] In a large-span building, 18 circular pipe columns are arranged in a circular manner and scattered. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com