Oil-proof and anti-corrosion PVC cable material and preparation method thereof

A cable material, anti-corrosion technology, applied in plastic/resin/wax insulators, organic insulators, etc., can solve the problems of difficulty in batch use, special processing performance, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

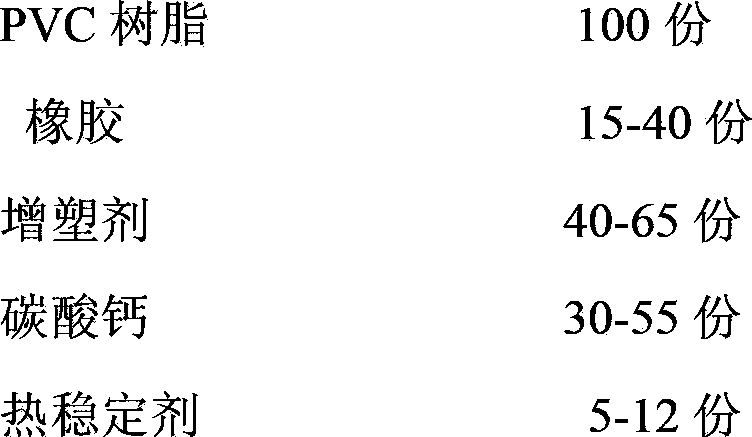

Method used

Image

Examples

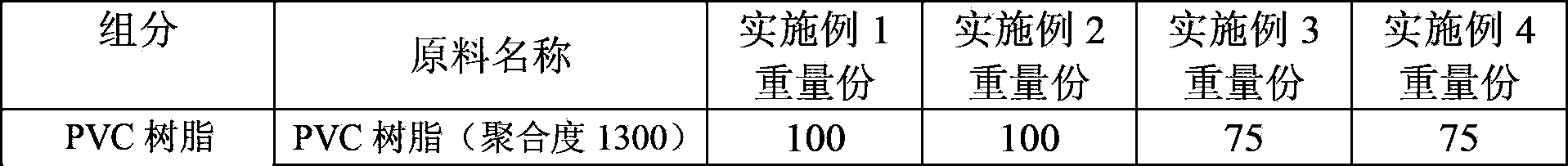

Embodiment 1~ Embodiment 4

[0029] 1. Experimental materials

[0030] The composition and proportioning of raw materials are shown in Table 1 below.

[0031] PVC resin (polymerization degree 1300) was purchased from Ningbo Formosa Plastics Company; PVC resin (polymerization degree 2500) was purchased from Shanghai Chlor-Alkali Chemical Company; ethylene-propylene rubber was purchased from DuPont; nitrile rubber was purchased from Korea LG Company; neoprene rubber , purchased from Japan Denki Chemical Corporation; calcium-zinc composite heat stabilizer, organotin heat stabilizer purchased from Germany Bear brand.

[0032] 2. Experimental method

[0033] Put the PVC resin, heat stabilizer, lubricant, and antioxidant in a high-speed kneader and heat it for low-speed mixing. The speed is 500 rpm. After the plasticizer is completely added, start high-speed mixing, and the high-speed mixing speed is 1500rpm;

[0034] Mix at high speed until the plasticizer is absorbed by the powder, start low speed when the...

Embodiment 5~ Embodiment 8

[0045] 1. Experimental materials

[0046] PVC resin (polymerization degree 1300) was purchased from Ningbo Formosa Plastics Company; PVC resin (polymerization degree 2500) was purchased from Shanghai Chlor-Alkali Chemical Company; ethylene-propylene rubber was purchased from DuPont; nitrile rubber was purchased from Korea LG Company; neoprene rubber , purchased from Japan Denki Chemical Corporation; calcium-zinc composite heat stabilizer, organotin heat stabilizer purchased from Germany Bear brand.

[0047] The composition and proportioning of raw materials are shown in Table 3 below.

[0048] 11. Experimental method

[0049] Put the PVC resin, heat stabilizer, lubricant, and antioxidant in a high-speed kneader and heat it for low-speed mixing. The mixing speed is 1000rpm, and the temperature of the high-speed kneader is controlled at about 115°C. At the same time, the plasticizer is added in two times. After the plasticizer is completely added, start high-speed mixing, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com