Anti-falling device and method for wagon turnover device

A flipping machine and anti-fall technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low safety factor of flipping machine, falling of the operating table, production safety accidents, etc., and achieve automation The effect of high degree of protection, prevention of further falling, and guarantee of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

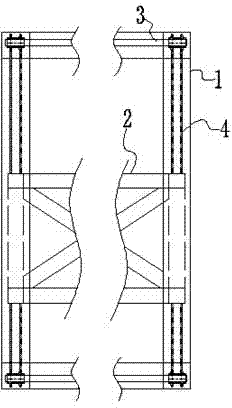

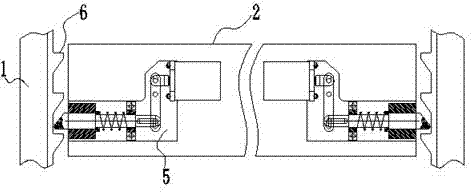

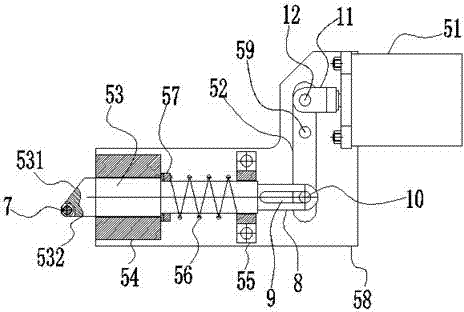

[0030] Embodiment 1: as Figure 2 to Figure 5 As shown, a kind of anti-falling device that is used for the turning machine of railway wagon includes the automatic latch mechanism 5 fixedly arranged on both sides of the turning machine console 2; the rack 6 fixedly arranged on the turning machine frame 1 on both sides, each The automatic latch mechanism 5 on the side comprises a cylinder or a hydraulic cylinder 51, which is fixedly arranged on the side of the turning machine console 2; a connecting plate 52, which is hinged at the side of the turning machine console 2 in the middle; a latch rod 53; Block seat 54 and mounting seat 55, it is all fixedly arranged on the side of described turning machine console 2, and described slide block seat 54 and mounting seat 55 all have the through hole that passes for described latch rod 53, so One end of the latch rod 53 passes through the through hole of the slider seat 54, and the other end passes through the through hole of the mountin...

Embodiment 2

[0040] Embodiment 2: as Figure 8 and Figure 9 As shown, compared with Embodiment 1, the difference is that the anti-falling device also includes a rotation speed detection device arranged on the turning machine for detecting the rotation speed of the rotating shaft 3 of the chain lifting device, and the rotation speed detection device includes a setting The encoder 13 on the transmission shaft 3 of the chain lifting device and the detection switch 14 arranged on the frame 1 of the turning machine; the PLC controller; the encoder and the detection switch are connected with the electrical control of the PLC controller ; The solenoid valve controlling the action of the air cylinder or the hydraulic cylinder is connected with the electrical control of the PLC controller.

[0041] Such as Figure 8 As shown, this embodiment also discloses a fall prevention method of the above-mentioned fall prevention device, which is in the process of raising and lowering the operating platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com