Square billet low-medium carbon steel continuous casting crystallizer mold powder and production method thereof

A technology of continuous casting crystallizer and production method, which is applied in the field of metallurgical auxiliary materials, can solve problems such as instability, prone to segregation, and reduce the types of base materials, so as to achieve high added value, save mining, reduce a large amount of accumulation and serious pollution problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

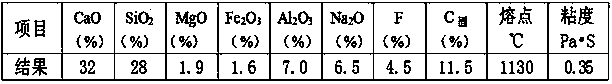

[0030] The formula of yellow phosphorus waste residue in the above-mentioned production process can be shown in the following table:

[0031]

[0032] If conventional raw materials are used, the formula is shown in the table below:

[0033]

[0034] From the comparison of the above data, it can be seen that 24% of yellow phosphorus waste slag replaces 7% of fluorite, 3% of bauxite, 6% of glass stone, 7% of wollastonite, 4% of calcite, and 2% of ice crystal in the original formula. stone, plus 5% quartz. The raw material cost of the original formula is 1324.8 yuan / ton, and the yellow phosphorus waste residue is calculated at 350 yuan / ton. The raw material cost of the new formula is 1015.4 yuan, and the raw material cost is reduced by 309.4 yuan / ton.

[0035] In the process ③ in the batching and pulping, the pulping time is 60min, and the water content of the slurry is 31%; ④The pump pressure of the spray granulation plunger pump is 2.5MPa, the liquid supply rate is 21...

Embodiment 2

[0038] The formula of yellow phosphorus waste residue in the above-mentioned production process can also be shown in the following table:

[0039]

[0040] If conventional raw materials are used, the formula is shown in the table below:

[0041]

[0042] From the comparison of the above data, it can be seen that 30% of the yellow phosphorus waste slag replaces 2.5% of fluorite, 1% of bauxite, 31% of wollastonite, 1% of cryolite in the original formula, plus 3.5% of quartz and 2% of calcite . The raw material cost of the original formula is 1250.5 yuan / ton, and the yellow phosphorus waste residue is calculated at 350 yuan / ton. The raw material cost of the new formula is 994.4 yuan, and the raw material cost is reduced by 256.1 yuan / ton.

[0043] In the process ③ in the batching and slurrying, the slurrying time is 65min, and the water content of the slurry is 33%; ④The pump pressure of the spray granulation plunger pump is 2.7MPa, the liquid supply rate is 23mL / min, the ...

Embodiment 3

[0046] The formula of yellow phosphorus waste residue in the above-mentioned production process can also be shown in the following table:

[0047]

[0048] If conventional raw materials are used, the formula is shown in the table below:

[0049]

[0050] From the comparison of the above data, it can be seen that 27% of yellow phosphorus waste slag replaces 3% of fluorite, 2% of bauxite, 7% of limestone, 3% of bentonite, 18% of wollastonite and 3% of ice crystal in the original formula. Stone, plus 4% quartz, 5% calcite. The raw material cost of the original formula is 1317.9 yuan / ton, and the yellow phosphorus waste residue is calculated at 350 yuan / ton. The raw material cost of the new formula is 1033.4 yuan, and the raw material cost is reduced by 284.5 yuan / ton.

[0051] In the process ③ in the batching and slurry making, the slurry making time is 70min, and the water content of the slurry is 34%; ④The pump pressure of the spray granulation plunger pump is 2.9MPa, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com