Molecular sieve adsorption tower

A technology of molecular sieve and adsorption tower, which is applied in the field of gas drying, can solve the problems of easy crystallization, troublesome maintenance, and increased maintenance costs, and achieve the effects of small mutual friction, easy removal and replacement, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

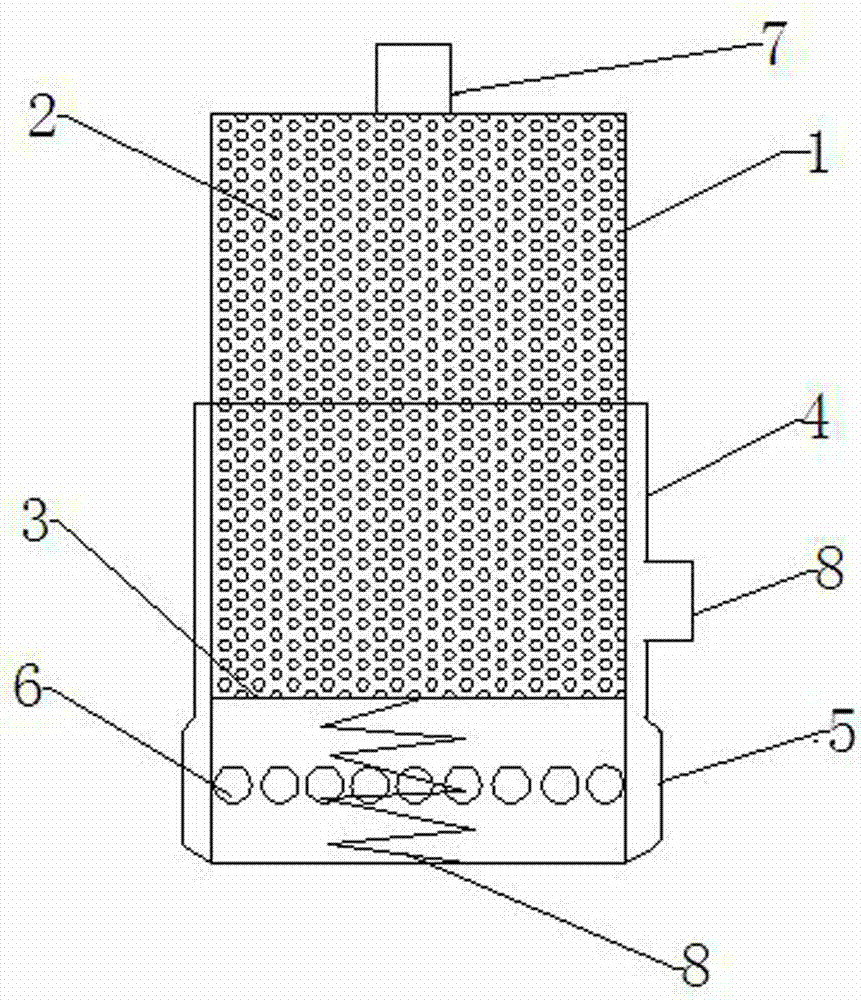

[0018] Such as figure 1 As shown, a molecular sieve adsorption tower includes a cylinder 1 and a molecular sieve 2, the cylinder 1 is provided with an air flow equalizer 3, and the molecular sieve 2 is arranged in a cavity formed by the air flow equalizer 3 and the end face of the top of the cylinder 1, There is a reserved space between the air flow equalizer 3 and the end surface of the bottom surface of the cylinder body 1; the surface of the air flow equalizer 3 is uniformly provided with air holes.

[0019] The cylinder body 1 is covered with an outer tube 4, the two ends of the cylinder body 1 protrude from the outer tube 4, a cavity is formed between the inner wall of the outer tube 4 and the cylinder body 1, the top of the outer tube 4 is sealed and connected with the outer wall of the cylinder body 1, and the outer tube There is a gap between the bottom end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com