Textile-based wound debriding material and manufacturing method thereof

A wound-together technology, which is applied in the field of textile-based wound debridement materials and its manufacturing, can solve problems such as difficult flow and pressure control, unsafe and hygienic conditions, and patient wound injuries, and achieve good dimensional stability and efficient debridement methods , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

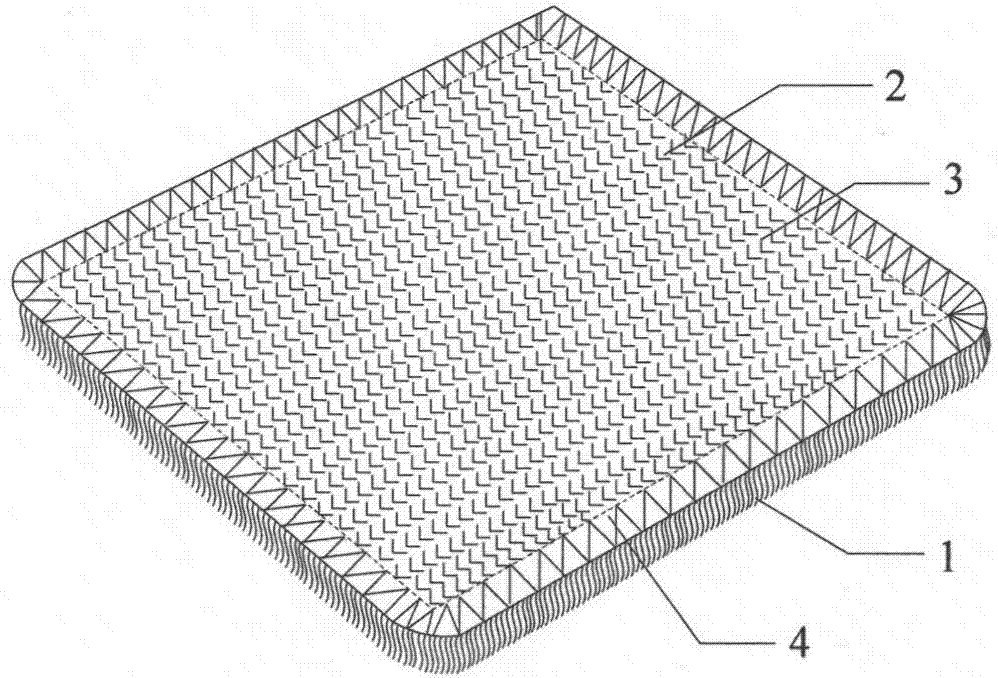

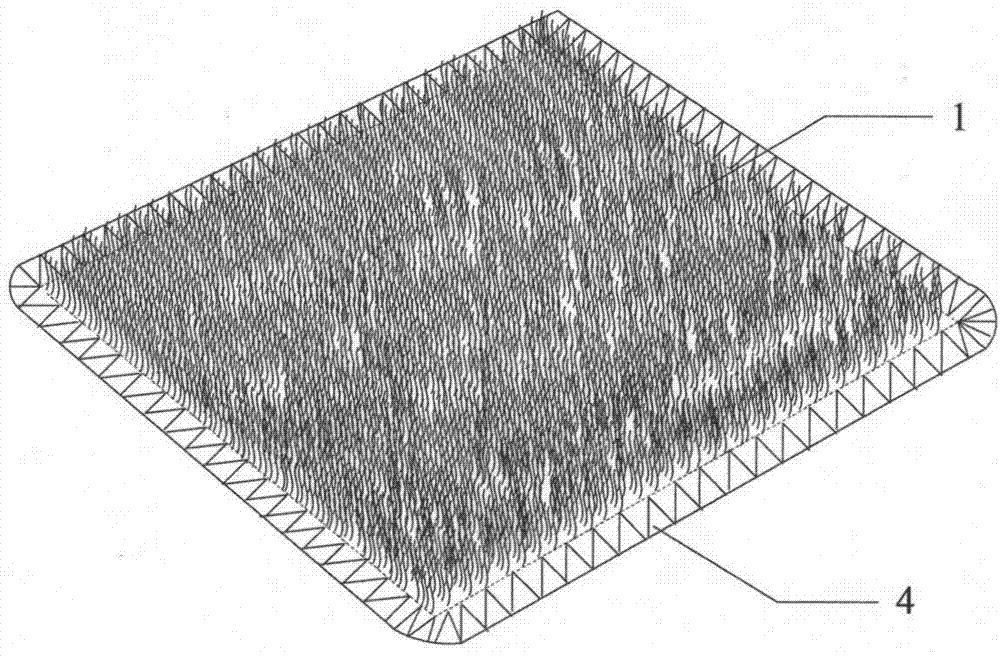

[0051] A textile-based wound debridement material includes a knitted composite structure, the knitted composite structure includes a ground tissue 2 and a fleece fiber 1, the fleece fiber 1 is located on the front of the ground tissue 2, and the roots of the fleece fiber 1 and the ground tissue 2 are woven together And bonded and fixed by adhesive 3. The surrounding of the knitted composite structure is provided with hemming material 4 . Figure 1a , 1b and 1c are schematic diagrams of the structure of the back, front and cross-section of the textile-based wound debridement material, respectively.

[0052] The velvet fiber 1 is made of 2.2D, 28mm long bio-grade polyester staple fiber. The ground texture 2 is woven on a circular knitting machine using 150D / 36F biological grade polyester low elastic yarn. The ground weave 2 adopts a knitted weft flat weave. Figure 2a It is the coil diagram of suede ground, Figure 2b Weaving diagram for suede texture, Figure 2c For the ba...

Embodiment 2

[0059] A textile-based wound debridement material includes a knitted composite structure, the knitted composite structure includes a ground tissue 2 and a fleece fiber 1, the fleece fiber 1 is located on the front of the ground tissue 2, and the roots of the fleece fiber 1 and the ground tissue 2 are woven together And bonded and fixed by adhesive 3. The surrounding of the knitted composite structure is provided with hemming material 4 . Figure 1a , 1b and 1c are schematic diagrams of the structure of the back, front and cross-section of the textile-based wound debridement material, respectively.

[0060] The velvet fiber 1 is made of 1.5D, 38mm long bio-grade polyester staple fiber. The ground texture 2 is woven on a circular knitting machine using 300D / 72F biological grade polyester low elastic yarn. The ground weave 2 adopts a knitted weft flat weave. Figure 2a It is the coil diagram of suede ground, Figure 2b Weaving diagram for suede texture, Figure 2c For the ba...

Embodiment 3

[0067] A textile-based wound debridement material includes a knitted composite structure, the knitted composite structure includes a ground tissue 2 and a fleece fiber 1, the fleece fiber 1 is located on the front of the ground tissue 2, and the roots of the fleece fiber 1 and the ground tissue 2 are woven together And bonded and fixed by adhesive 3. The surrounding of the knitted composite structure is provided with hemming material 4 . Figure 1a , 1b and 1c are schematic diagrams of the structure of the back, front and cross-section of the textile-based wound debridement material, respectively.

[0068] The velvet fiber 1 is made of 2D, 64mm long bio-grade polyester staple fiber strips. The ground texture 2 is woven on a circular knitting machine using 150D / 48F biological grade polyester low elastic yarn. The ground weave 2 adopts a knitted weft flat weave. Figure 2a It is the coil diagram of suede ground, Figure 2b Weaving diagram for suede texture, Figure 2c For t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com