The Method of Rebaking and Alcoholization for Reducing Ammonia Release

A technology of ammonia release and alcoholization, applied in tobacco, food science, tobacco preparation and other directions, can solve the problems of lack of attention, no patents and literature reports, etc., and achieve the effect of improving degradation and transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

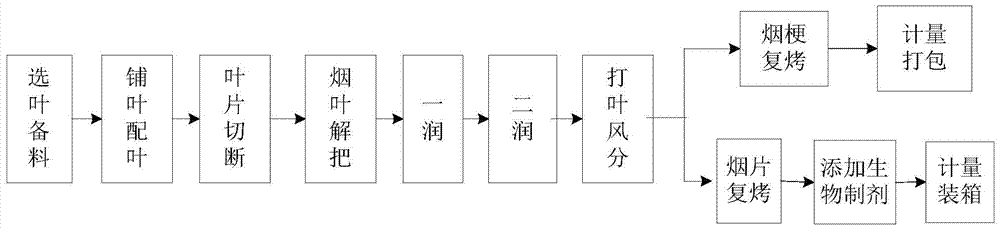

Method used

Image

Examples

Embodiment 1

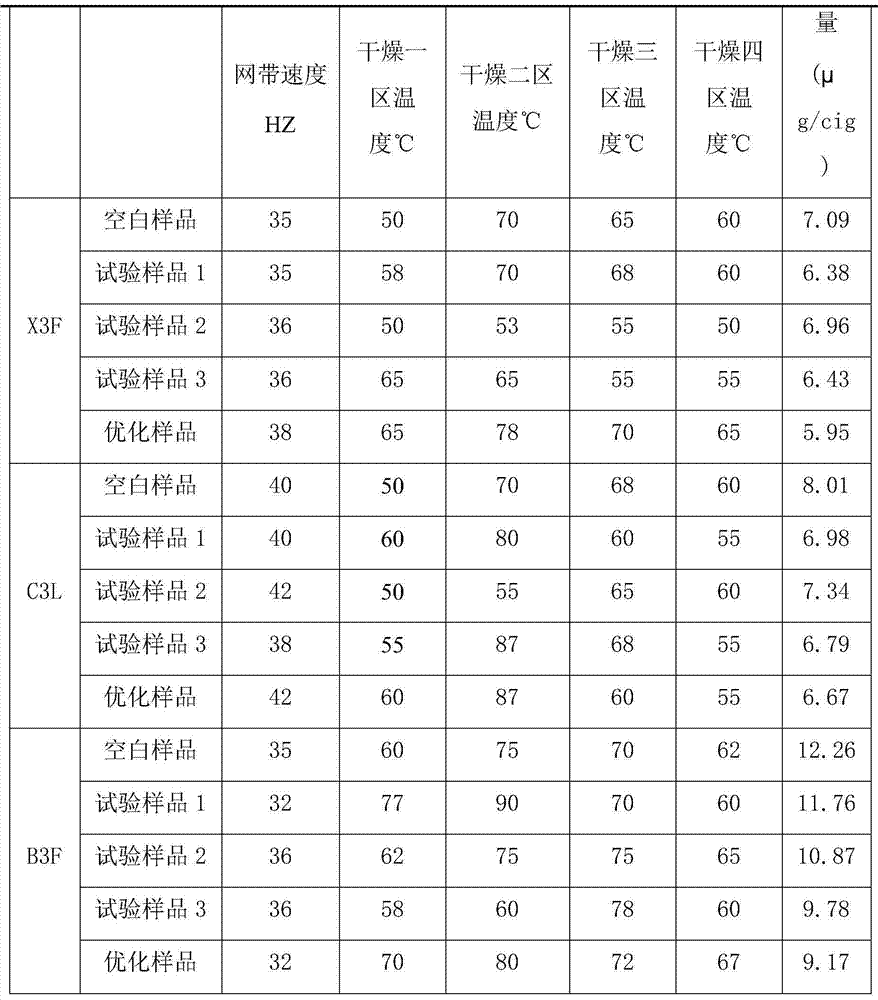

[0022] The tobacco leaf sample produced according to the existing threshing and redrying process parameters is used as a blank sample; in the tobacco sheet redrying process, the lower 2011 X3F tobacco leaves, the middle 2011 C3L tobacco leaves, and the upper 2011 B3F tobacco leaves, The process parameters were adjusted according to the combination of optimized processing process parameters, and the process parameters of other processes were kept unchanged, and the tobacco leaf samples produced were optimized samples; the tobacco leaf samples of each group were loosely rehydrated, shredded, and naturally air-cured under the same conditions, and the cigarette samples were rolled. The ammonia content of flue gas in the samples is shown in Table 1.

[0023] Table 1 Test results of ammonia content in samples optimized for rebaking process and blank samples

[0024]

[0025]

[0026] It can be seen from Table 1 that the ammonia content in the flue gas of the tobacco samples pr...

Embodiment 2

[0028] The tobacco leaf samples produced according to the existing threshing and redrying process parameters were used as blank samples; Add the same proportion of biological agent aqueous solution, the biological agent is composed of Bacillus subtilis, Bacillus amyloliquefaciens, and Bacillus circulans, according to the mass percentage of 1:2:2, and use water as a solvent to prepare a 0.8‰ biological agent Aqueous solution, the content of Bacillus subtilis in biological preparations is 1×10 13 CFU / g, Bacillus amyloliquefaciens bacteria content 1×10 11 CFU / g, Bacillus circulans content 1×10 11 CFU / g; the technological parameters of the other processes remain unchanged, and the tobacco leaf sample obtained from production is the optimized sample; the cigarette sample is rolled after aging under the same conditions, loosening and rehydration, shredding, and natural drying under the same conditions. The detection of ammonia content in the smoke of the samples is shown in Table ...

Embodiment 3

[0034] The tobacco leaf samples produced according to the existing threshing and redrying process parameters were used as blank samples; Add the same proportion of biological agent aqueous solution, the biological agent is composed of Bacillus subtilis and Bacillus amyloliquefaciens, according to the mass percentage of 2:1, using water as a solvent, prepare a 1.5‰ biological agent aqueous solution, the biological agent contains Bacillus subtilis bacteria Volume 1×10 14 CFU / g, Bacillus amyloliquefaciens bacteria content 1×10 12CFU / g; the technological parameters of the other processes remain unchanged, and the tobacco leaf sample obtained from production is the optimized sample; the cigarette sample is rolled after aging under the same conditions, loosening and rehydration, shredding, and natural drying under the same conditions. The detection of ammonia content in the smoke of the samples is shown in Table 3, and 2% in the table means that the addition amount of the biologica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com