Electric pruning shears

A pruning shears, electric technology, used in cutting tools, cutting equipment, gardening and other directions, can solve the problems of burning out the motor, reducing the axial pressure, parts wear, etc., to extend the service life, the braking effect is good, the effect The effect of force equalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

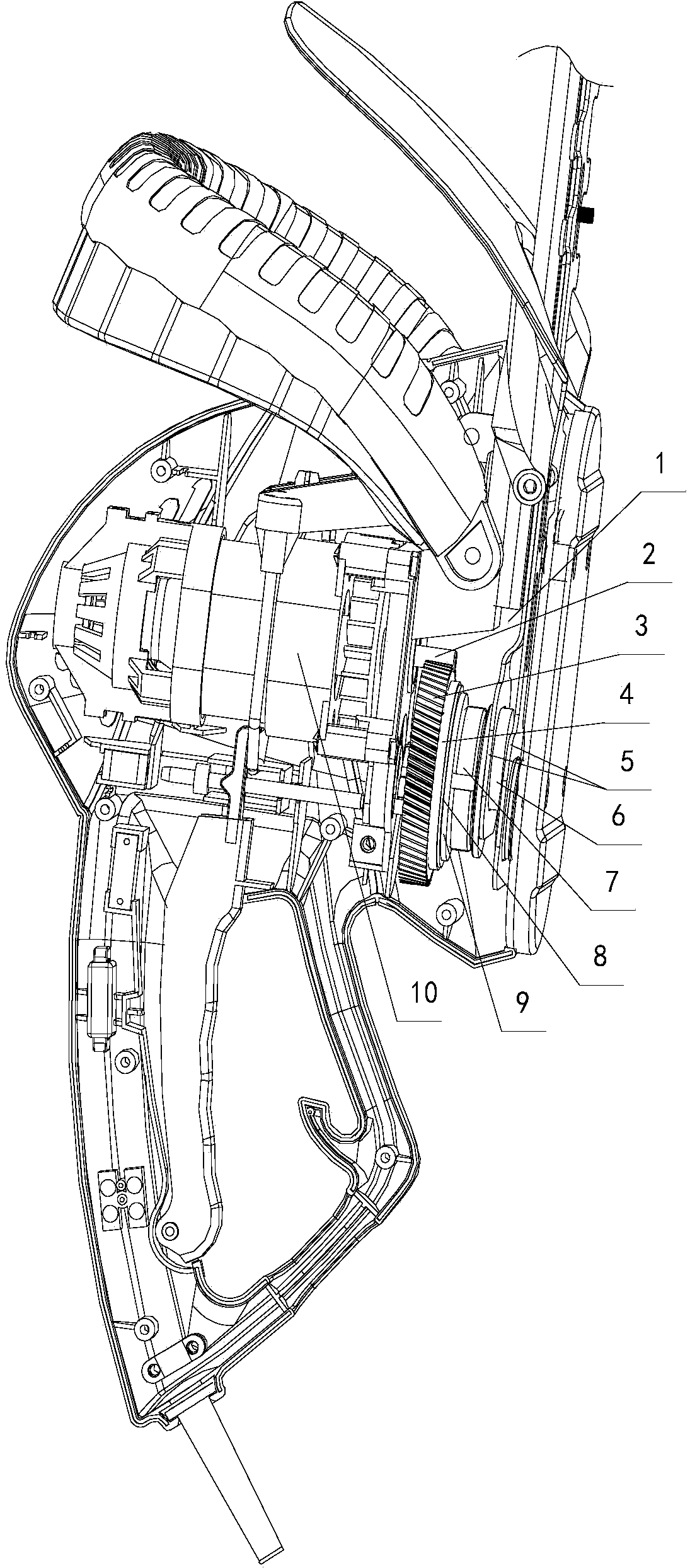

[0018] Depend on Figure 1 to Figure 4 As can be seen from the shown schematic diagram of the structure of the electric pruning shears of the present invention, it includes a casing 1, a motor 10, a transmission and a shear blade 5, the motor 10 is installed in the casing 1, and the output shaft of the motor 10 is connected to the shears by the transmission. Cutting blade 5 is connected. The transmission device includes an input gear 2, an output gear 3 and an eccentric block assembly. The input gear 2 is connected to the output shaft of the motor 10, and the output gear 3 meshed with the input gear 2 is rotatably connected in the casing 1 and passed through the eccentric block assembly. Connect with shear blade 5. Described eccentric block assembly comprises eccentric block 6 and eccentric block cover 11, and one end of eccentric b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com