Electric capstan

A technology of electric winches and transmission shafts, which is applied in the direction of mechanical drive clutches, couplings and brakes, clutches that mesh with each other, etc., and can solve damage, insufficient width of the third-stage sun gear and the second-stage planet carrier, and failure of the winch Use and other problems to achieve the effect of improving the use effect and braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described below with reference to the accompanying drawings; however, it should be understood that the structural proportions in the accompanying drawings are only exemplary and not intended to limit the scope of the present disclosure.

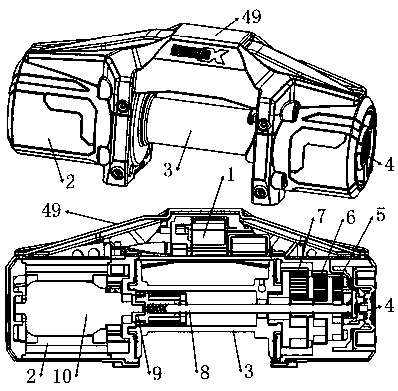

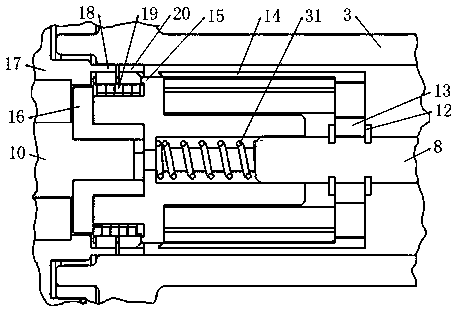

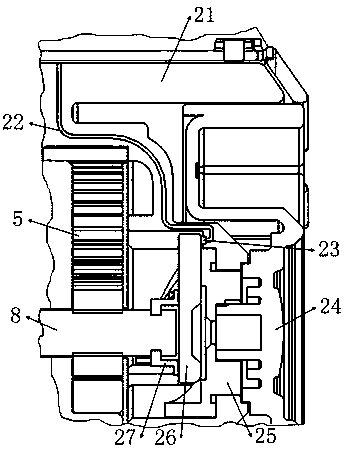

[0040] An electric winch, such as figure 1 As shown, it includes an outer shell 49, an electric control module 1 is housed in the upper side of the outer shell 49, a motor module 2 is housed in the left end side of the outer shell 49 and a deceleration module and a clutch 4 are housed in the right end side, and a middle part of the lower side of the outer shell 49 is equipped with Drum 3, the motor 10 in the motor module 2 drives the transmission shaft 8 located in the drum 3 to rotate through the brake unit 9, the transmission shaft 8 drives the rotation of the drum 3 through the deceleration module, and the clutch 4 controls the axial movement of the transmission shaft 8; the above deceleration The modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com