Electrode for non-aqueous electrolyte rechargeable battery, non-aqueous electrolyte rechargeable battery, and battery pack

A non-aqueous electrolyte and secondary battery technology, which is applied in the direction of non-aqueous electrolyte battery electrodes, non-aqueous electrolyte batteries, battery electrodes, etc., and can solve the problem of reduced adhesion between active materials and conductive materials, reduced capacity, and weak bonding strength, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

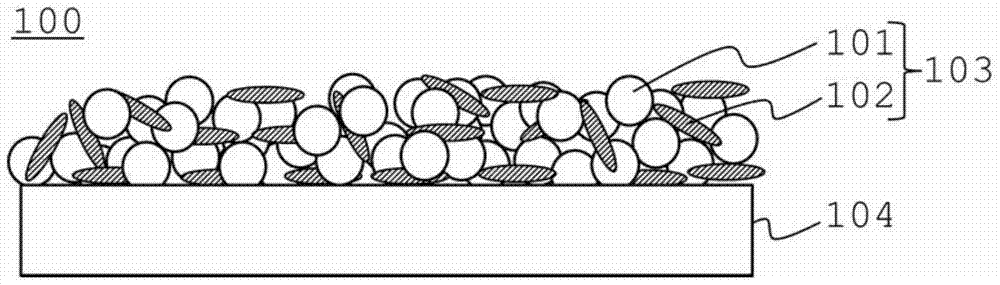

[0022] As a first embodiment of the present invention, a case where the electrode is a negative electrode will be described below as an example.

[0023] Such as figure 1 As shown in the conceptual diagram of , the negative electrode 100 of the first embodiment has: a layered negative electrode active material layer 103 that includes a negative electrode active material 101 and a binding material 102 that binds the negative electrode active material 101; Bonded current collector 104 . The negative electrode active material layer 103 is formed on one or both surfaces of the current collector 104 . In the following, symbols are omitted except when referring to the drawings.

[0024] The negative electrode active material of the embodiment performs intercalation and deintercalation of Li. As the negative electrode active material, those containing metal elements among negative electrode active materials that can be used in nonaqueous electrolyte secondary batteries can be used...

no. 2 approach )

[0054] A nonaqueous electrolyte secondary battery according to a second embodiment will be described.

[0055] The nonaqueous electrolyte secondary battery of the second embodiment includes a positive electrode, a negative electrode, a nonaqueous electrolyte layer formed between the positive electrode and the negative electrode, and a case for accommodating the positive electrode, the negative electrode, and the electrolyte.

[0056] Referring to an example of the non-aqueous electrolyte secondary battery 200 showing the embodiment Figure 5 The concept map is described in further detail. Figure 5 It is a conceptual cross-sectional view of a flat non-aqueous electrolyte secondary battery 200 in which a bag-like exterior material 202 is formed of a laminated film.

[0057] The flat wound electrode group 201 is accommodated in a bag-shaped outer packaging material 202 composed of a laminated film sandwiching aluminum foil between two resin layers. As part of the concept map a...

no. 3 approach )

[0112] Next, a battery pack according to a third embodiment will be described.

[0113] The battery pack of the third embodiment has one or more nonaqueous electrolyte secondary batteries (ie, single cells) of the second embodiment described above. When the battery pack includes a plurality of cells, the cells may be configured to be electrically connected in series, in parallel, or in series and in parallel.

[0114] refer to Figure 7 concept map of and Figure 8 The block diagram of the battery pack 300 is described in detail. exist Figure 7 In the battery pack 300 shown, it is used as a single battery 301 Figure 5 The flat type non-aqueous electrolyte battery 200 is shown.

[0115] A battery pack 305 is constituted by a plurality of single cells 301 by stacking them so that the negative terminal 302 and the positive terminal 303 extending outward are aligned in the same direction, and connecting them with an adhesive tape 304 . These single cells 301 as Image 6 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com