Etching device reaction chamber electrode and etching device

A technology for etching equipment and reaction chambers, applied in circuits, discharge tubes, electrical components, etc., can solve the problem of cumbersome removal of electrode holes, save time for electrode maintenance, improve performance, and be easy to maintain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

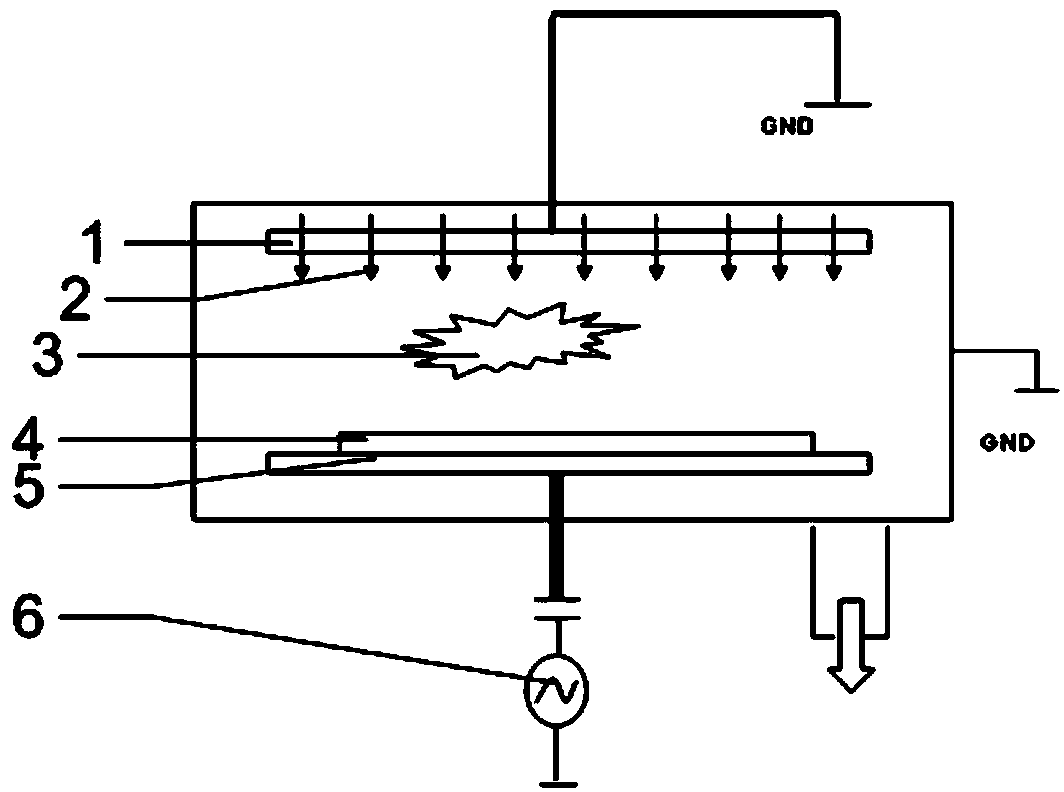

[0027] An embodiment of the present invention provides an electrode of a reaction chamber of an etching device. The etching device is preferably a dry etching device, and the electrode is preferably an upper electrode of the reaction chamber of the dry etching device. The dry etching equipment can be used to etch the film layer deposited on the substrate during the manufacturing process of liquid crystal display, organic light emitting diode display and the like.

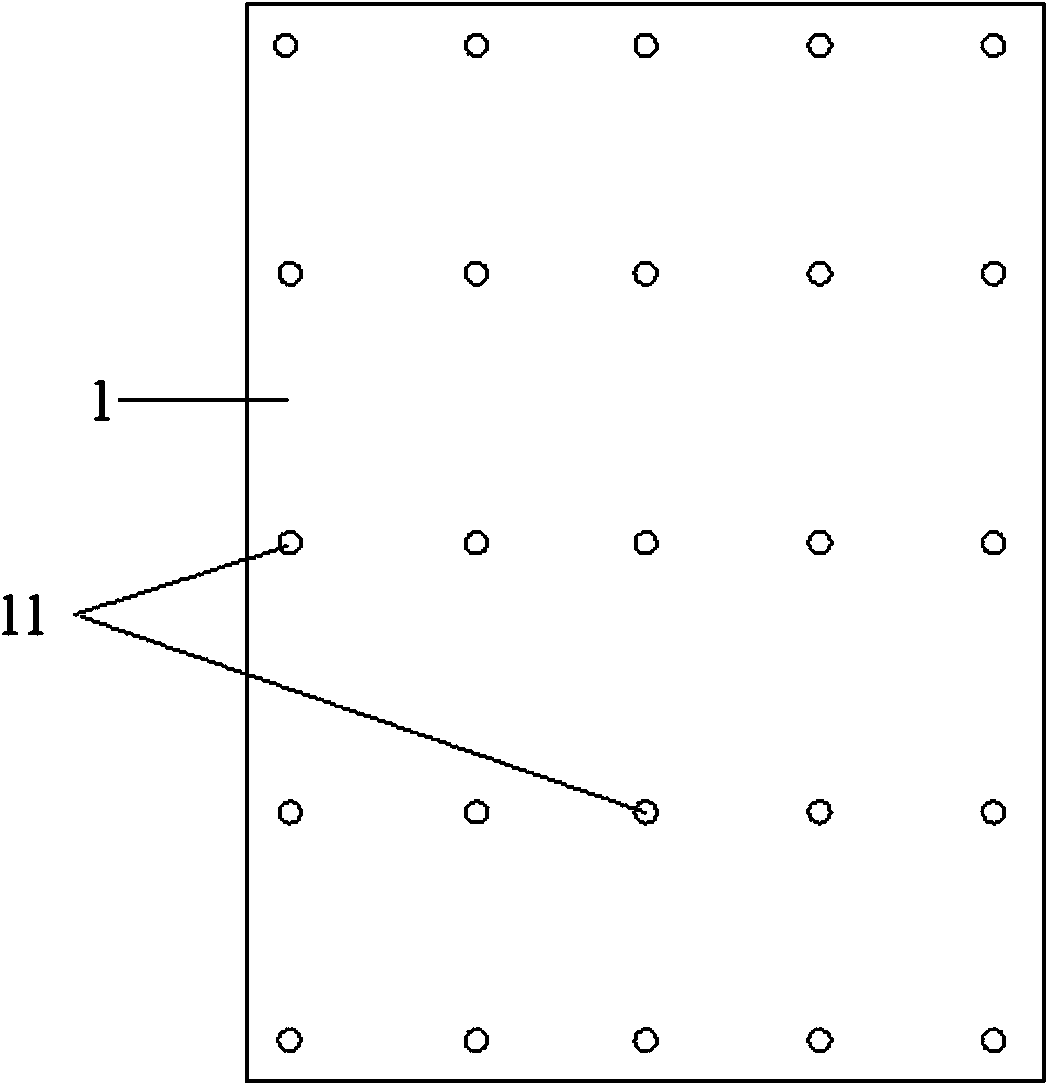

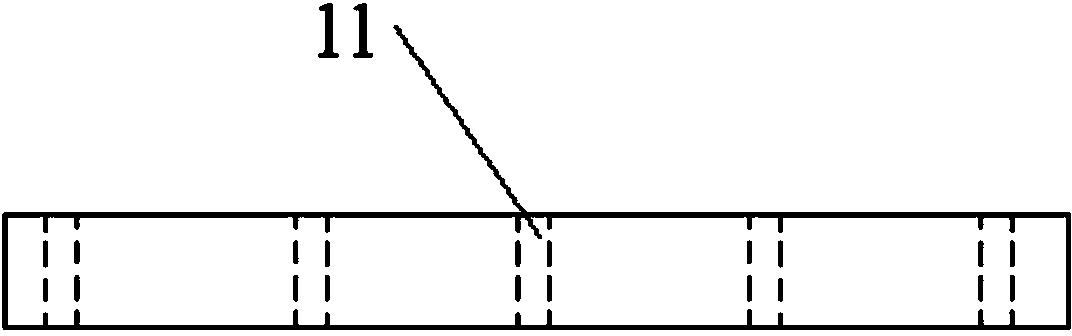

[0028] Such as Figure 4 to Figure 6 As shown, the electrode of this embodiment includes a flat plate 8, and the flat plate 8 is provided with a plurality of first through holes 12, and the electrode also includes a plurality of inserts 7 with second through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com