Electronic component

一种电子部件、构件的技术,应用在混合电容器端子、电解电容器、混合/双电层电容器制造等方向,能够解决耐压下降、出现裂缝、壳体2熔化等问题,达到抑制润湿扩展的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

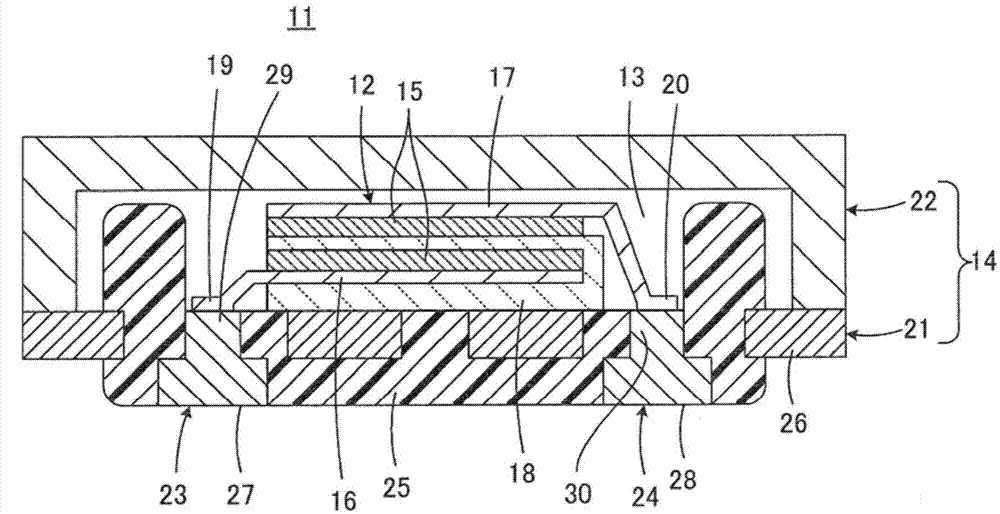

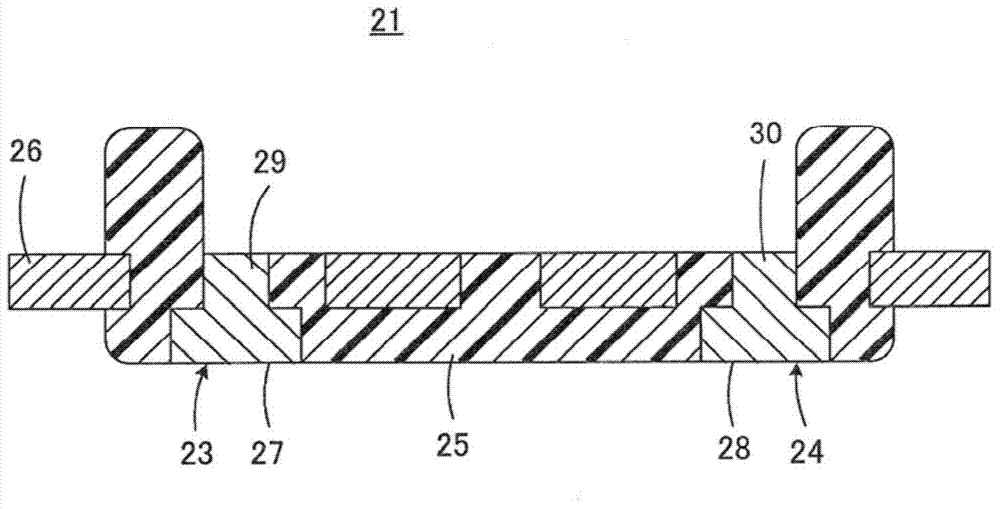

[0062] As a plate, an aluminum plate with a thickness of 0.5 mm was prepared, and after zincate treatment (zincate treatment) was implemented on one of its main surfaces, a matte nickel plated film with a thickness of 0.66 μm was formed as a base plated film, and a thickness of 0.66 μm was formed on it. 0.15μm gold plating film, as the outer layer plating film. Afterwards, by implementing the reference image 3 The described press forming and the like can obtain the external terminal member according to the examples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com