Main-transformation coiled-tube-type heat-dissipating device with SF6 (sulfur hexafluoride) as refrigerant medium and heat-dissipating method

A heat dissipation device and coil-type technology, applied in the direction of transformer/inductor cooling, etc., can solve the problems of low cooling efficiency of the main transformer, large manufacturing volume, high operating cost, etc. high cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

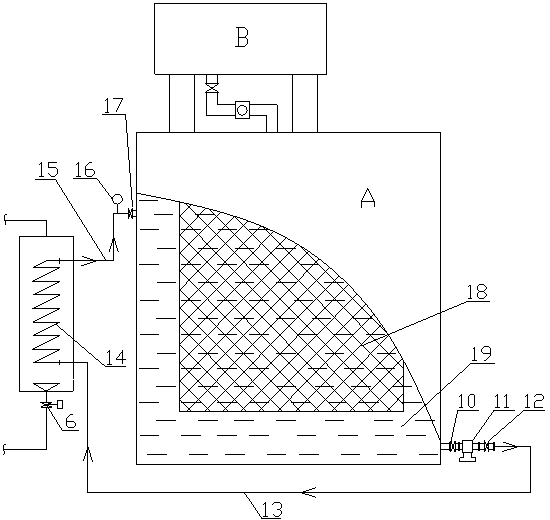

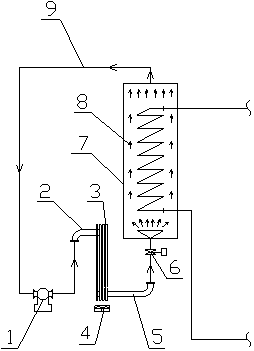

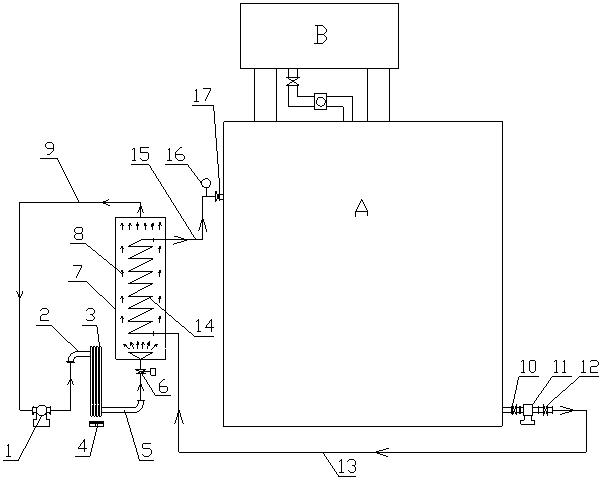

[0018] Such as Figure 1~3 shown, a SF 6 The main transformer coil type cooling device is a cold medium, and the transformer oil flow cooling circulation system and SF 6 Composed of refrigerant circulation system, the transformer oil flow cooling circulation system includes main transformer body A, oil pump 11 and coil type SF 6 The tube side 14 of the evaporator 7, the main transformer body A is filled with transformer oil 19 for cooling the coil and the iron core 18, and the upper part of the main transformer body A is provided with a cold oil inlet and a cold oil inlet for inputting cold transformer oil. Oil inlet valve 17, the lower part of the main transformer body A is provided with a thermal oil outlet for outputting thermal transformer oil and a thermal oil outlet valve 10, and the oil pump 11 transports thermal transformer oil 19 from the thermal oil outlet to the coil type SF 6 The tube side 14 inlet of the evaporator 7, the thermal transformer oil is SF 6 SF sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com