Micro Quartz Furnace Atomizer

A technology of atomizer and quartz, which is applied in the atomization field of atomic fluorescence, to achieve the effects of low argon gas consumption, improved reliability and reduced power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

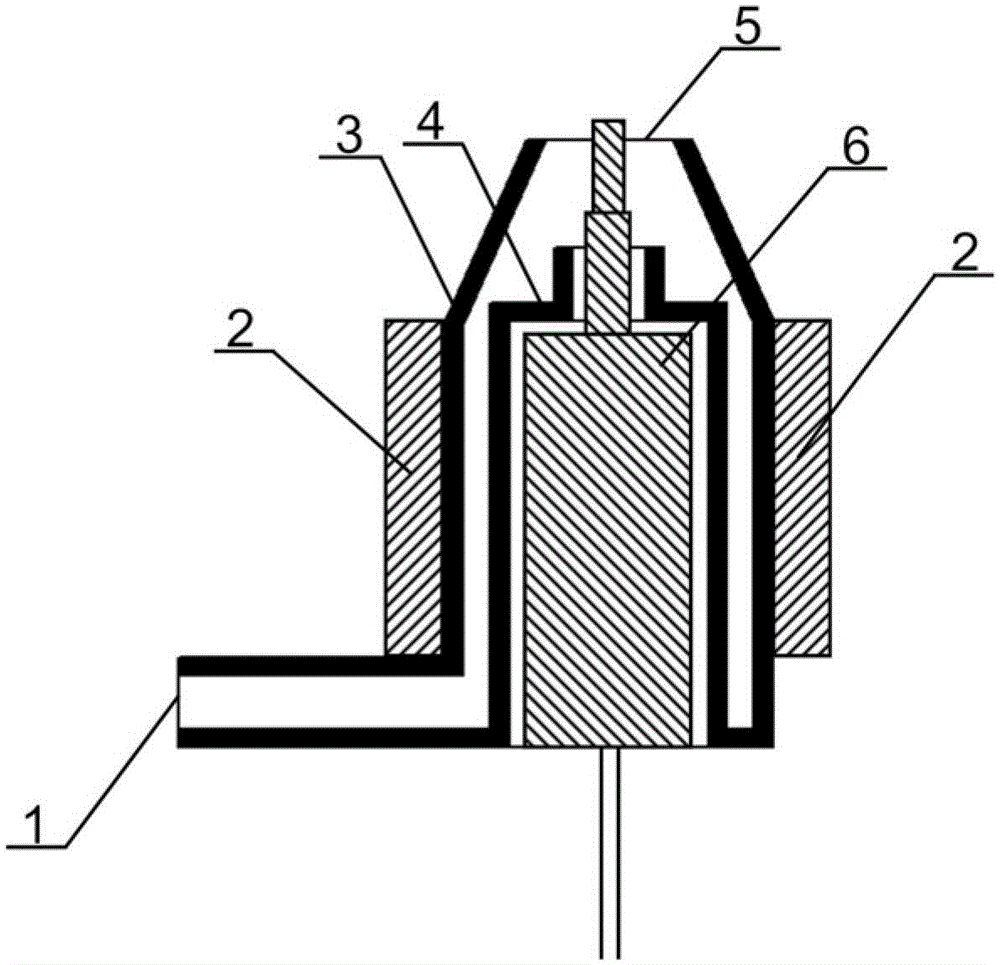

[0029] Relevant present invention is for reaching above-mentioned purpose of use and effect and the technical means adopted, presents preferred feasible embodiment, and cooperates as shown in the accompanying drawings, detailed description is as follows:

[0030] The present invention provides a miniature quartz furnace atomizer, comprising a heating device 2, an outer layer furnace tube 3, an inner layer furnace tube 4 and a hot surface igniter 6 arranged sequentially from outside to inside, wherein the outer layer furnace tube 3 and the inner furnace tube 4 form a gas channel, one end of the gas channel is provided with an air inlet 1, and the other end is tapered to form a gas outlet 5, and the heating device 2 is arranged on the outer layer furnace tube 3 The outer peripheral surface of the gas is used to heat the gas, and the hot surface igniter 6 is arranged in the inner furnace tube 4, and the ignition pin of the hot surface igniter 6 extends to the gas outlet 5 , for i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com