A multi-functional packer that can be repeatedly set at low pressure after the first high-pressure setting

A multi-functional, packer technology, applied in sealing/isolation, wellbore/well parts, earthwork drilling and production, etc., can solve the problems of large well washing channel, damage, small well washing channel, etc., and achieve effective sealing section Long, simple construction process, and small well washing channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

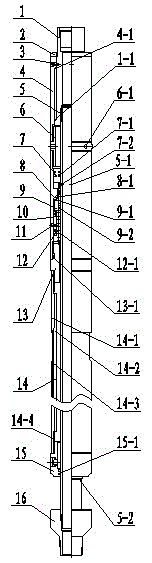

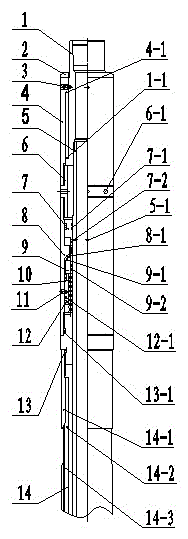

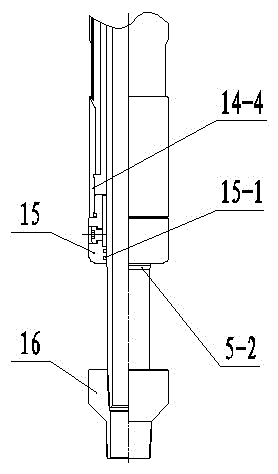

[0026] The multifunctional packer that can be repeatedly set at low pressure after the first high-pressure setting is described in detail below in conjunction with the accompanying drawings, taking water injection wells as an example.

[0027] The multifunctional packer that can be repeatedly set at low pressure after the first high-pressure setting is composed of an upper joint 1, a limit step 1-1, an anti-collision hanging ring 2, an unsealing pin 3, an upper connector 4, and a limit step 4- 1. Central pipe 5, water inlet 5-1, variable diameter pressure relief step 5-2, filter screen connector 6, well flushing inlet 6-1, well flushing piston 7, sealing ring 7-1, well flushing pen tip key 7-2, lower connecting body 8, sealing seat 8-1, setting piston 9, special-shaped seal 9-1, sealing ring 9-2, spring 10, first setting pin 11, first setting sliding sleeve 12, seal Ring 12-1, plastic tube metal pipe joint 13, sealing ring 13-1, sealing rubber tube assembly 14, upper metal joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com