Pressure resistant tool for reducing frictional resistance of horizontal well section

A horizontal well section and anti-backpressure technology, which is applied in drilling equipment, directional drilling, and driving devices for drilling in boreholes. problems, to achieve the effect of increasing ROP, reducing drilling steps, and increasing uniform contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

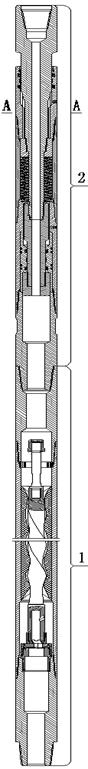

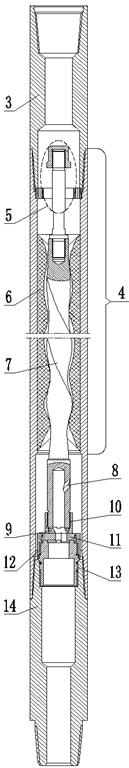

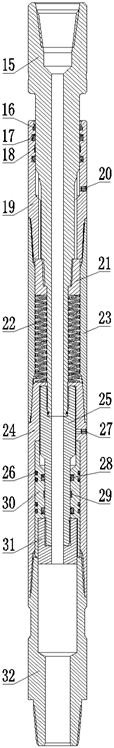

[0018] Such as Figure 1-Figure 5 As shown in the figure, an anti-back pressure tool for reducing friction in horizontal well sections is composed of a pulse component 1 and a vibrating component 2; , an upper fixed sleeve 10, a lower anti-wear block 11, a lower fixed sleeve 12, a lower valve body 13 and a lower joint 14; the upper joint 3 is connected to the upper end of the power part 4 through threads, and the lower joint 14 is connected to the lower end of the power part 4 through threads , the lower valve body 13 is threadedly connected in the inner hole of the upper end of the lower joint 14, the lower anti-wear block 11 is installed on the upper end of the lower valve body 13, and the lower fixed sleeve 12 is threaded and fixed with the lower valve body 13; the vibrating part 2 is mainly driven by a spline Shaft 15, spline centering cylinder 19, upper seal group, lock nut 21, disc spring 22, fixed sleeve 23, support housing 24, piston rod 25, piston sleeve 30, piston nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com