Conductive copper alloy for magnetoelectric device and preparation method thereof

A technology for conductive copper alloys and magnetoelectric devices, applied in the field of metal materials, can solve problems such as low electrical conductivity of materials, and achieve the effects of ensuring mechanical properties, ensuring electrical conductivity, and reducing raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

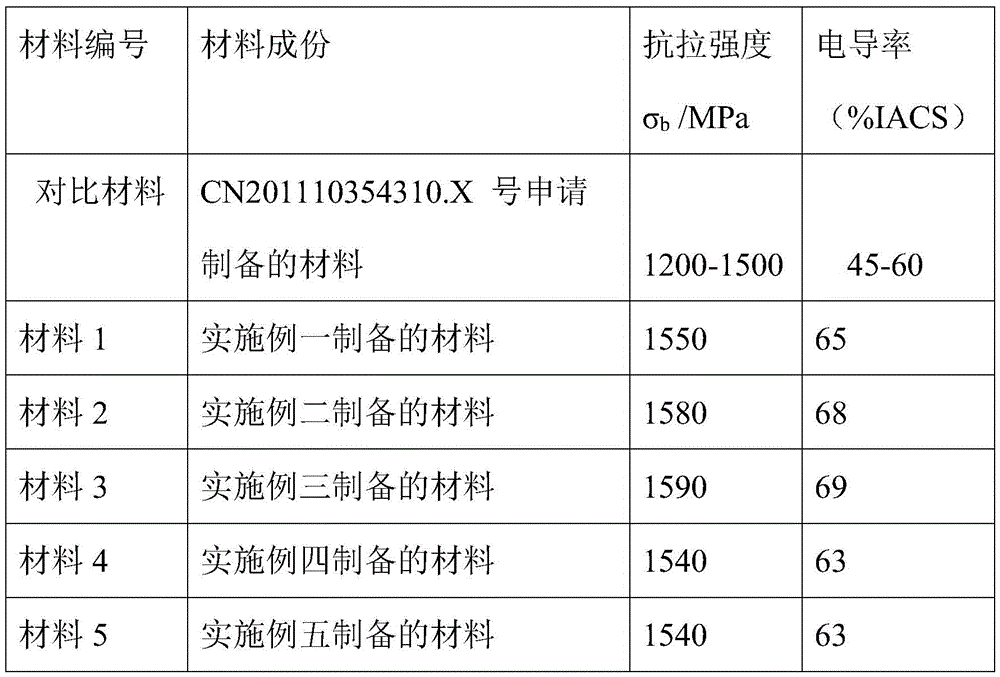

Embodiment 1

[0027] The conductive copper alloy for magnetoelectric devices of the present invention has the weight percentage of each component: 0.03% of Sm, 0.01% of Nd, 0.01% of Fe, 0.04% of Sb, 0.03% of Be, and the rest is Cu.

[0028] The preparation method of conductive copper alloy for magnetoelectric device of the present invention comprises the following steps:

[0029] 1) First, the ingredients are prepared according to the above-mentioned ingredients, and the raw materials Sm, Nd, Fe, Sb, Be, and Cu are added in the form of pure substances, and the purity is greater than 99.9%;

[0030] 2) Then put the raw materials into the graphite crucible, then put the crucible into the induction furnace, and then vacuumize it. When the vacuum degree in the induction furnace reaches 5×10 -2 Start heating after Pa, after the alloy is heated to 1280°C, stop power supply and vacuum after 15 minutes of heat preservation; after the pressure in the induction furnace reaches atmospheric pressure, o...

Embodiment 2

[0033] The conductive copper alloy for magnetoelectric devices of the present invention has the weight percentage of each component: 0.05% of Sm, 0.03% of Nd, 0.03% of Fe, 0.06% of Sb, 0.06% of Be, and the rest is Cu.

[0034] The preparation method of conductive copper alloy for magnetoelectric device of the present invention comprises the following steps:

[0035] 1) First, the ingredients are prepared according to the above-mentioned ingredients, and the raw materials Sm, Nd, Fe, Sb, Be, and Cu are added in the form of pure substances, and the purity is greater than 99.9%;

[0036] 2) Then put the raw material into the graphite crucible, put the crucible into the induction furnace, and then vacuumize it. When the vacuum degree in the induction furnace reaches 8×10 -2 Start heating after Pa, after the alloy is heated to 1310°C, stop power supply and vacuum after 25 minutes of heat preservation; after the pressure in the induction furnace reaches atmospheric pressure, open th...

Embodiment 3

[0039] The conductive copper alloy for magnetoelectric devices of the present invention has the weight percentage of each component: Sm 0.04%, Nd 0.04%, Fe 0.02%, Sb 0.05%, Be 0.04%, and the rest is Cu.

[0040] The preparation method of conductive copper alloy for magnetoelectric device of the present invention comprises the following steps:

[0041] 1) First, the ingredients are prepared according to the above-mentioned ingredients, and the raw materials Sm, Nd, Fe, Sb, Be, and Cu are added in the form of pure substances, and the purity is greater than 99.9%;

[0042] 2) Then put the raw materials into the graphite crucible, then put the crucible into the induction furnace, and then vacuumize it. When the vacuum degree in the induction furnace reaches 6×10 -2 Heating starts after Pa. After the alloy is heated to 1300°C, stop power supply and vacuum after 20 minutes of heat preservation; after the pressure in the induction furnace reaches atmospheric pressure, open the furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com