Method for recovering nickel and cobalt through leaching laterite-nickel ore by using sulfuric and hydrochloric acid containing mixed waste acid

A technology of laterite nickel ore containing sulfuric acid, applied in the direction of improving process efficiency, etc., can solve the problems of high processing cost, difficult utilization, low production cost, etc., and achieve the effect of simple process path, low energy consumption and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

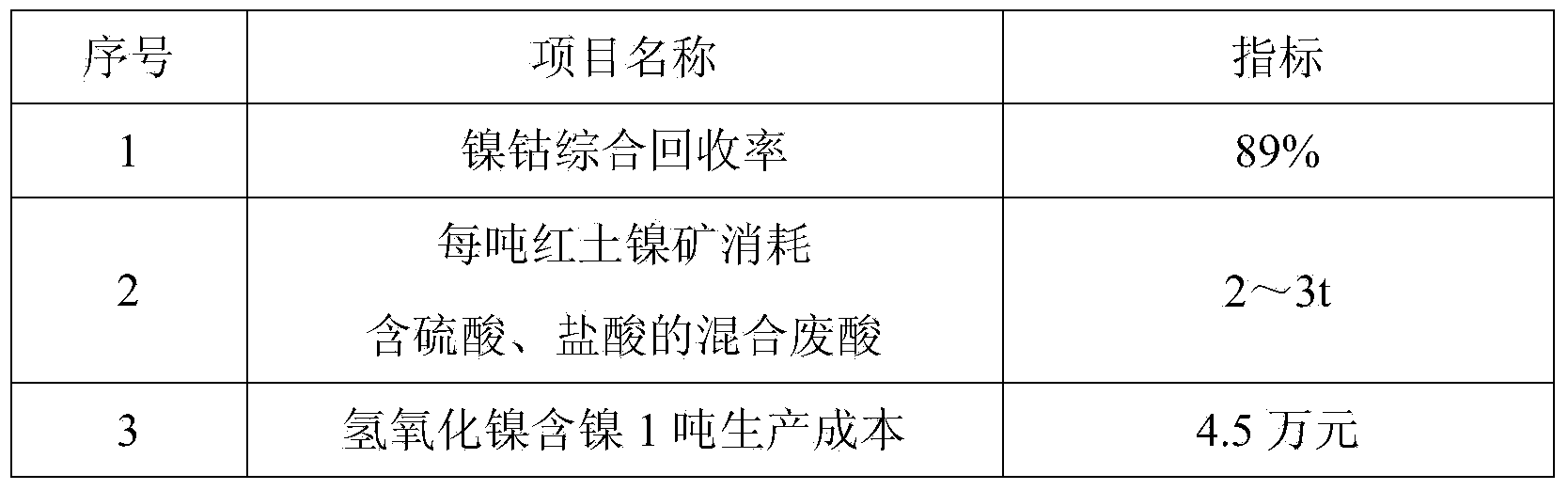

Examples

Embodiment 1

[0020] 1. Stirring and leaching of mixed waste acid containing sulfuric acid and hydrochloric acid

[0021] Laterite nickel ore crushing, grinding to below 0.15mm, using a filter area of 8m 2 Plate and frame filter press press filter into filter cake, prepare 400kg (50% moisture, 200kg dry ore). Its chemical composition is shown in the table below.

[0022] Chemical composition of laterite nickel ore

[0023] Ni%

Fe%

Mg%

Co%

1.4

13.8

12.2

0.10

[0024] 400kg mixed waste acid containing sulfuric acid and hydrochloric acid, H 2 SO 4 The content is 50%, the mass fraction of HCl is 10%, add to 2m 3 In the stirring tank, add the prepared 400kg laterite nickel ore (liquid-solid ratio 3:1) under the condition of stirring, heat to the temperature of 80, ℃ stirring and leaching for 6h, after the leaching is completed, use a filter area of 8m 2 Filter with a plate and frame filter press, add 110 kg of water directly to the filter ...

Embodiment 2

[0042] 1. Stirring and leaching of mixed waste acid containing sulfuric acid and hydrochloric acid

[0043] Laterite nickel ore crushing, grinding to below 0.15mm, using a filter area of 100m 2 The plate and frame filter press is used to filter into filter cakes, and 4 tons are prepared (moisture content is 50%, containing 2 tons of dry ore). Its chemical composition is shown in the table below.

[0044] Chemical composition of laterite nickel ore

[0045] Ni%

Fe%

Mg%

Co%

1.2

8.0

14.4

0.05

[0046] Mixed waste acid containing sulfuric acid and hydrochloric acid 6t, H 2 SO 4 The content is 10%, the mass fraction of HCl is 30%, add to 12m 3 In the stirring tank (liquid-solid ratio 5:1), add the prepared 4t laterite nickel ore under the condition of stirring, heat to the temperature of 60, ℃ stirring and leaching for 3 hours, after the leaching is completed, use a filter area of 100m 2 Filter with plate and frame filter pre...

Embodiment 3

[0064] 1. Stirring and leaching of mixed waste acid containing sulfuric acid and hydrochloric acid

[0065] Laterite nickel ore crushing, grinding to below 0.15mm, using a filter area of 100m 2 The plate and frame filter press is used to filter into filter cakes, and 4 tons are prepared (moisture content is 50%, containing 2 tons of dry ore). Its chemical composition is shown in the table below.

[0066] Chemical composition of laterite nickel ore

[0067] Ni%

Fe%

Mg%

Co%

1.3

10.0

11.2

0.05

[0068] Mixed waste acid containing sulfuric acid and hydrochloric acid 6t, H 2 SO 4 The content is 30%, the mass fraction of HCl is 20%, add to 12m 3 In the stirring tank (liquid-solid ratio 4:1), add the prepared 4t laterite nickel ore under the condition of stirring, heat to the temperature of 70°C, stir and leaching for 4.5h, after the leaching is completed, use a filter area of 100m 2 Filter with plate and frame filter press, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com