Compound microbial fertilizer with efficient disease prevention function and production method of compound microbial fertilizer

The technology of a compound microorganism and a production method is applied in the field of compound microorganism fertilizer with disease prevention function and production, which can solve the problems of environmental pollution, headaches for waste residue enterprises, waste of resources, etc., so as to reduce the degradation process, improve the utilization rate of fertilizers, and reduce the use of fertilizers. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

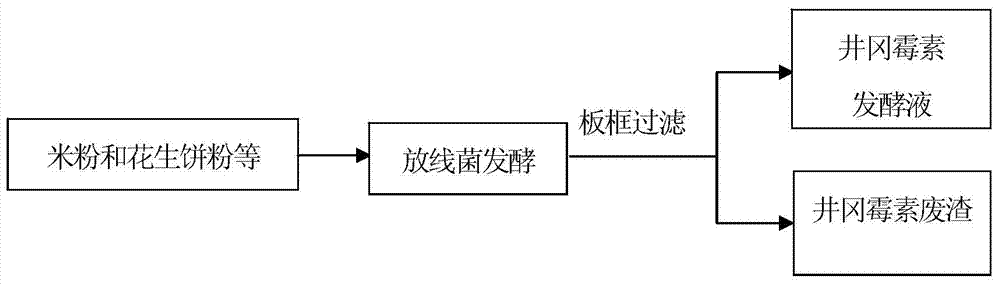

Method used

Image

Examples

Embodiment 1

[0048] 1. Sampling: The dregs in the production of Jinggangmycin were taken from Zhejiang Tonglu Huifeng Biochemical Co., Ltd.;

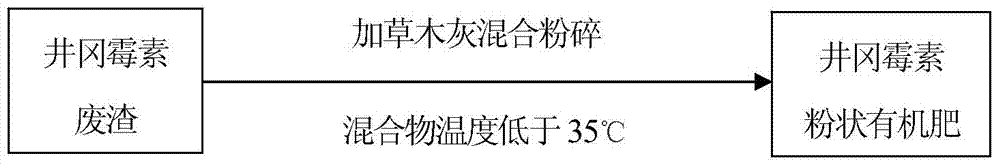

[0049] 2. pH adjustment: crush a large piece of Jinggangmycin residue into powder or small particles, mix it with plant ash according to the slag: plant ash=2:1, crush it with a chain mill, and stack it for 8-12 hours to allow it to fully react. In this process, the material can be turned over to make the maximum temperature not exceed 80 ℃, so as not to destroy the activity of Jinggangmycin;

[0050] 3. Overturning: Use a forklift or manual overturning to cool the reacted materials to normal temperature;

[0051] 4. Crushing: The dregs cooled to room temperature are measured. The basic properties are shown in Table 3. The content of heavy metals is far lower than the industry standard of bio-organic fertilizer, so no measurement was made;

[0052] Table 3 The basic properties of Jinggangmycin residue after treatment

[0053]

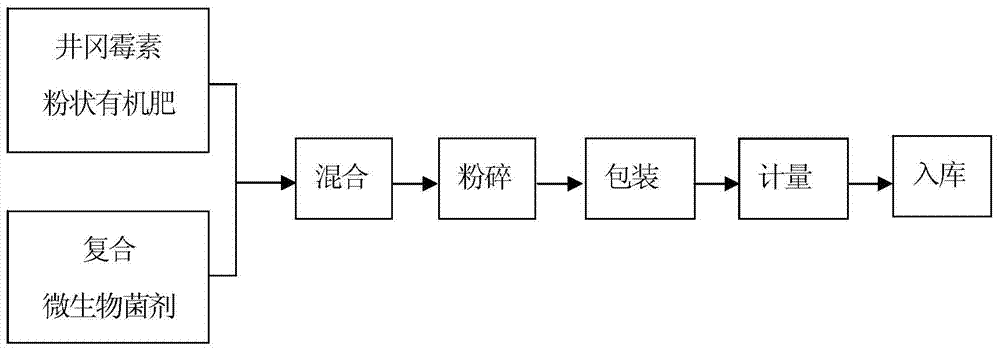

[0054] 5. Preparation of the c...

Embodiment 2

[0060] Except for the following processes, other things are the same as in Example 1. The compound microbial fertilizer with high-efficiency disease prevention function is produced by using Jinggangmycin dregs.

[0061] The mixing ratio of jinggangmycin dregs and plant ash is dregs: plant ash=3:2.

[0062] The biocontrol Bacillus subtilis HL259, Bacillus megaterium and Bacillus coli strains were separately fermented with rice husk powder at the ratio of bacterial solution: rice husk powder = 1:3. The two solid powdery inoculants are mixed according to the ratio of 1.5:1:1, and the effective number of live bacteria of the compound inoculants after mixing is 5.9×10 8 A / g or more, the moisture content is maintained at 25-28%.

[0063] Ingredients: Add 200kg of powdered Jinggangmycin dregs and 10kg of the above-mentioned composite microbial inoculum into the mixer.

Embodiment 3

[0065] Except for the following processes, other things are the same as in Example 1. The compound microbial fertilizer with high-efficiency disease prevention function is produced by using Jinggangmycin dregs.

[0066] The mixing ratio of Jinggangmycin dregs and plant ash is dregs: plant ash=1:1.

[0067] The biocontrol Bacillus subtilis HL259, Bacillus megaterium, and Bacillus coli strains are separately fermented with rice husk powder at the ratio of bacterial solution: rice husk powder = 1:5. Two kinds of solid powdery bacterial agents are mixed according to the ratio of 1:1:1.5, and the effective number of live bacteria of the compound bacterial agent after mixing is 5.8×10 8 A / g or more, the moisture content is kept at 21-24%.

[0068] Ingredients: Add 200kg of powdered Jinggangmycin dregs and 20kg of the above-mentioned composite microbial inoculum into the mixer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com