Method for preparing sphere-like mesoporous silica

A mesoporous silica, quasi-spherical technology, applied in the direction of silica, silica, etc., to prevent large-area leakage, high yield, and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Place a 100mL beaker on a magnetic stirrer, add 35mL of distilled water and heat up to 30°C, add 0.142g of CTAB to the distilled water under stirring, stir to form a transparent solution, add 0.055g of DDAB, and stir until completely dissolved.

[0029] Then add 0.69mL of ammonia water with a volume ratio of 25%. After stirring for 2 hours, slowly add 2.0g of TEOS to the mixture under stirring conditions. After sealing, stir and react at a constant temperature for 24 hours to obtain a white precipitate.

[0030] The obtained white precipitate solution was transferred to a 50mL reaction kettle, and placed in a thermostat at 100°C for 24h. After cooling, the white precipitate solution was filtered, and the obtained precipitate was repeatedly filtered and washed with distilled water.

[0031] The washed precipitate was dried at 50° C. for 12 hours, ground and then calcined in a tubular calciner at 550° C. for 6 hours to obtain spherical mesoporous silica.

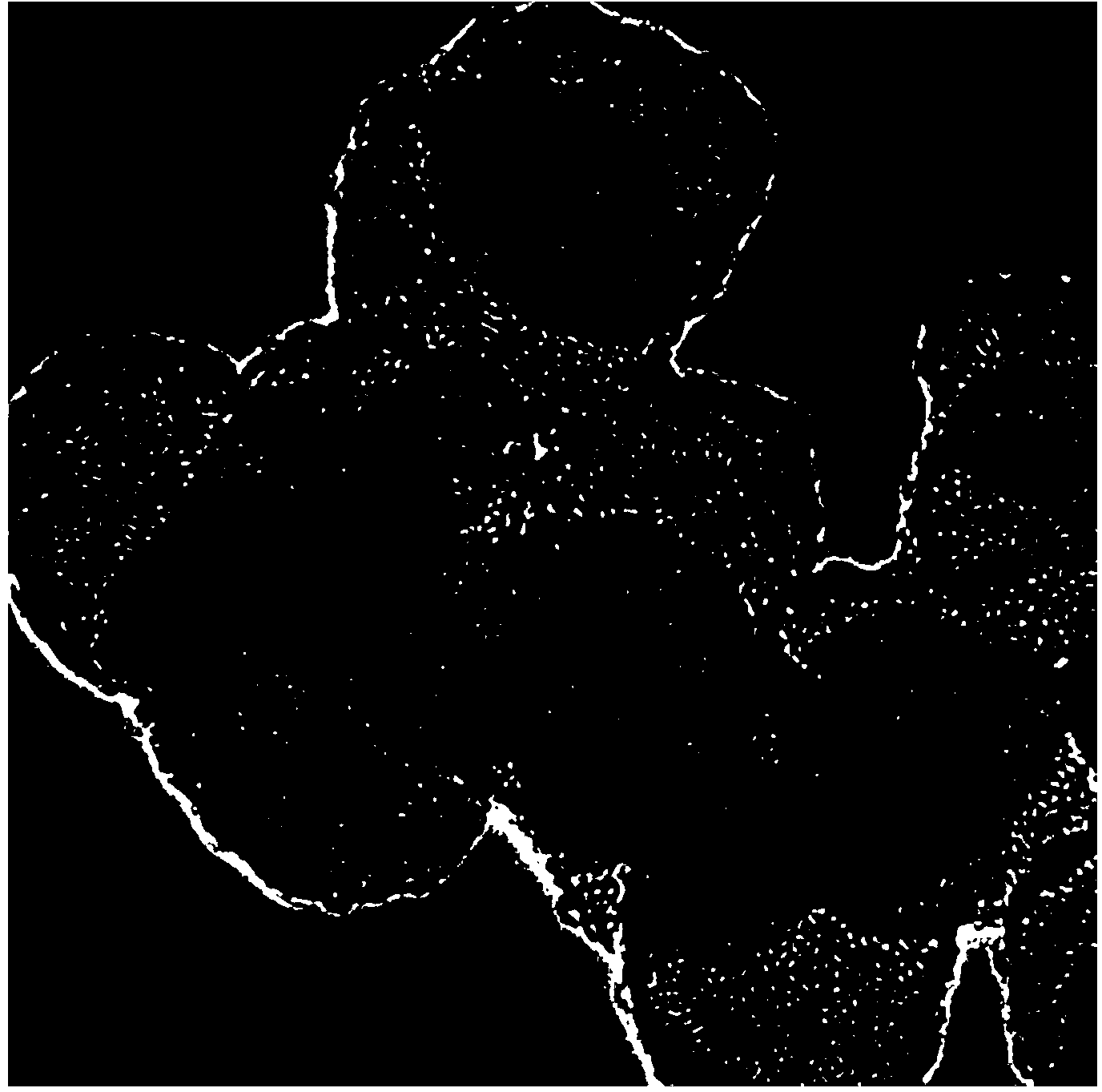

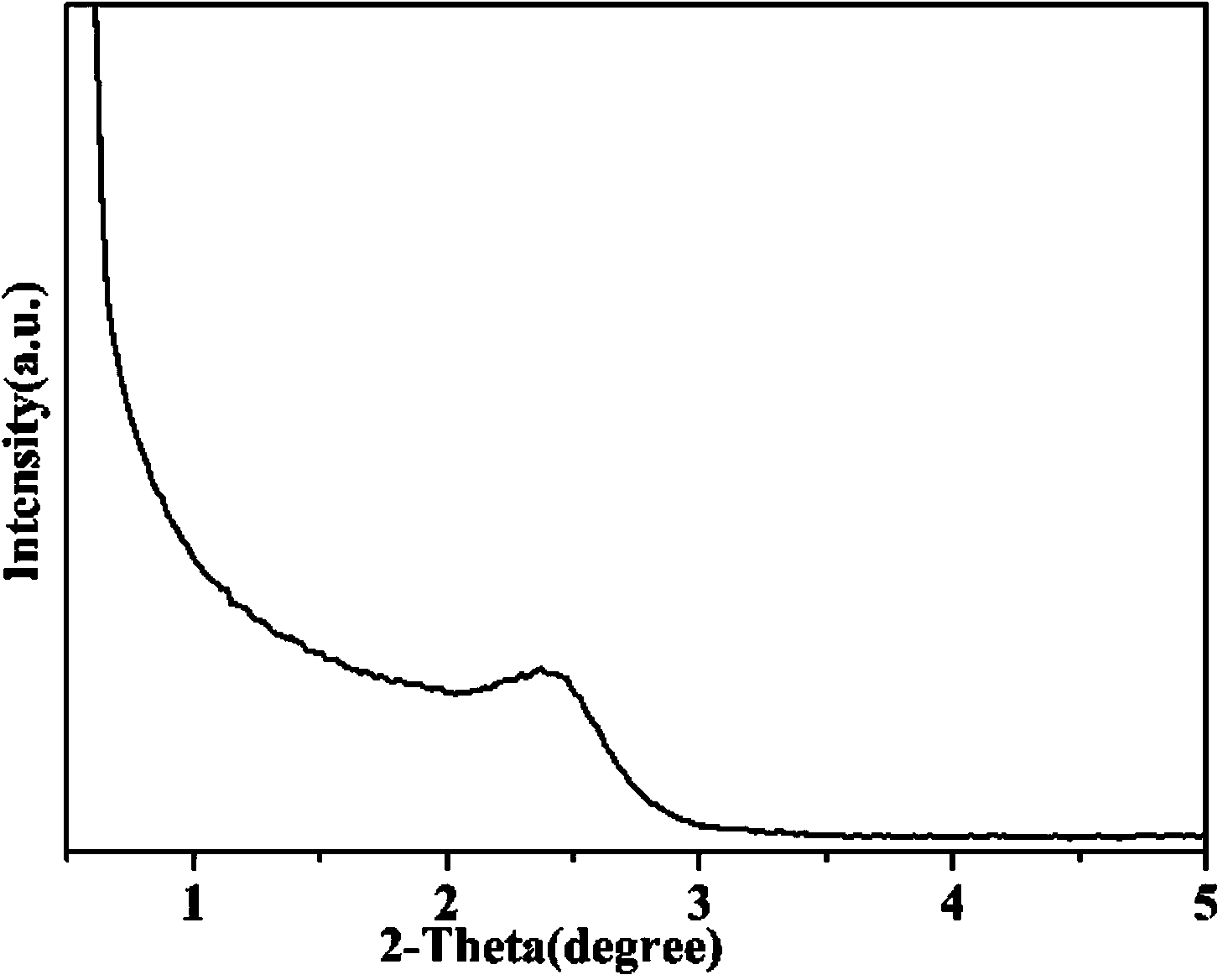

[0032] Observa...

Embodiment 2

[0034] Same as in Example 1, except that the amount of ammonia water added was changed to 0.96 mL, and other conditions remained unchanged, the morphology of the spherical mesoporous silica obtained was similar to that of Example 1.

Embodiment 3

[0036] As in Example 1, the amount of TEOS added was changed to 1.5 g, and other conditions remained unchanged, and the morphology of the spherical mesoporous silica obtained was similar to that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com