A tank washing machine with magnetic drive

A technology of magnetic drive and tank washing machine, which is applied to the cleaning equipment of ship liquid tanks, motor vehicles, ships, etc., and can solve problems such as wear, reduced equipment reliability, and equipment failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

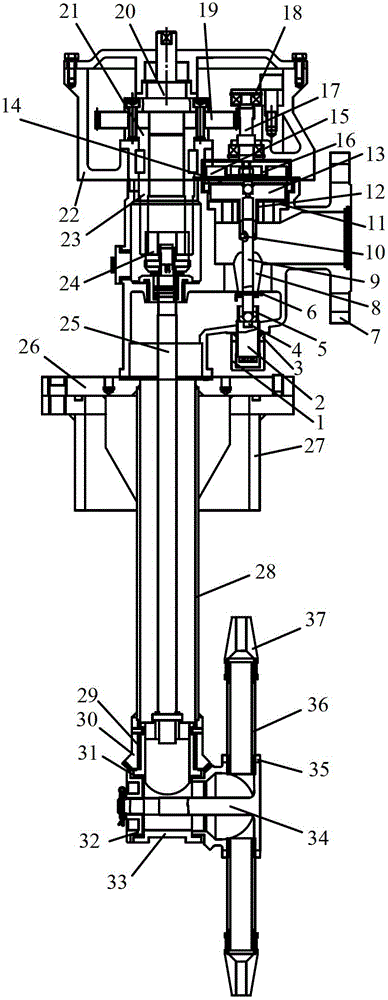

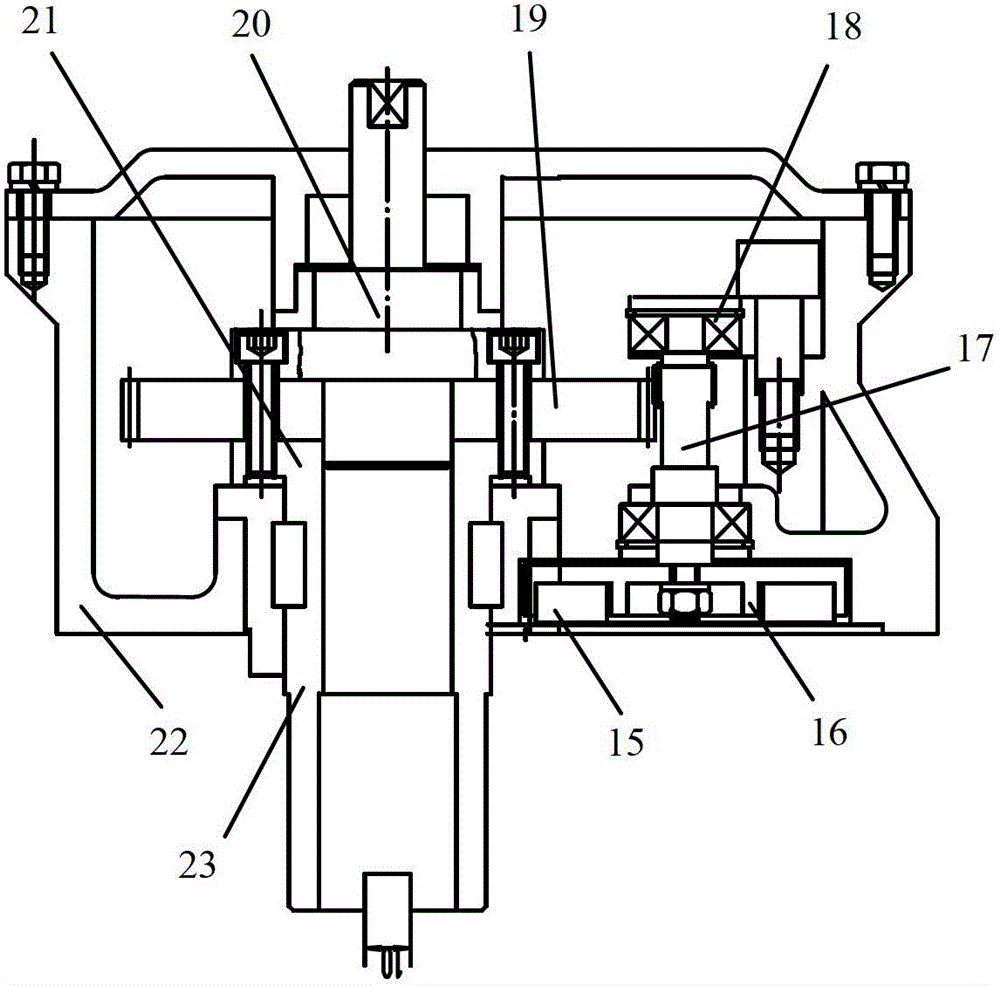

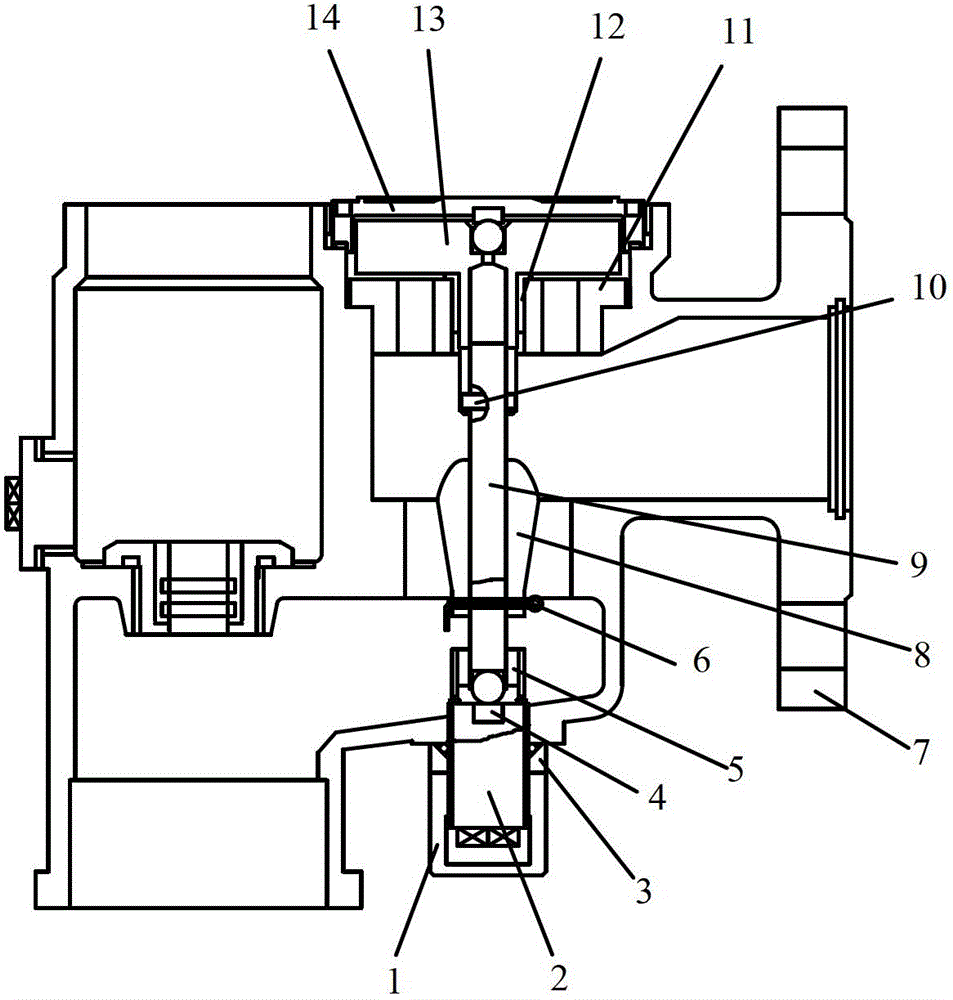

[0025] Embodiment 1, figure 1 A tank washing machine with magnetic drive is given, which consists of a reduction box ( figure 2 shown), power box ( image 3 shown) and body ( Figure 4 and Figure 5 shown) composition.

[0026] The power box includes a protective cover 1, a screw rod 2, a lock nut 3, a thrust block 4, a bearing 5, a hole pin 6, a power box body 7, a runner 8, a runner shaft 9, a connecting pin 10, a bearing sleeve 11, a shaft Cover 12, disk 13 and isolation cover 14; as image 3 As shown, the power box body 7 is provided with a power box cavity and a power box water inlet cavity, and the power box cavity and the power box water inlet cavity are connected to each other through a conical passage, and a water inlet is provided on the power box cavity; A runner shaft 9 is arranged in the cavity of the power box, and the upper end of the runner shaft 9 is fixed to the magnetic disk 13 through a connecting pin 10 (the magnetic disk 13 is made of magnetic mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com