Control system for production of four-color large-width print-coating steel plate

A color-coated steel plate and control system technology, applied in general parts of printing machinery, printing, printing machines, etc., can solve the problems of inability to adapt to the diversified needs of the market, limited use surface, simple decorative effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: Monochrome long format

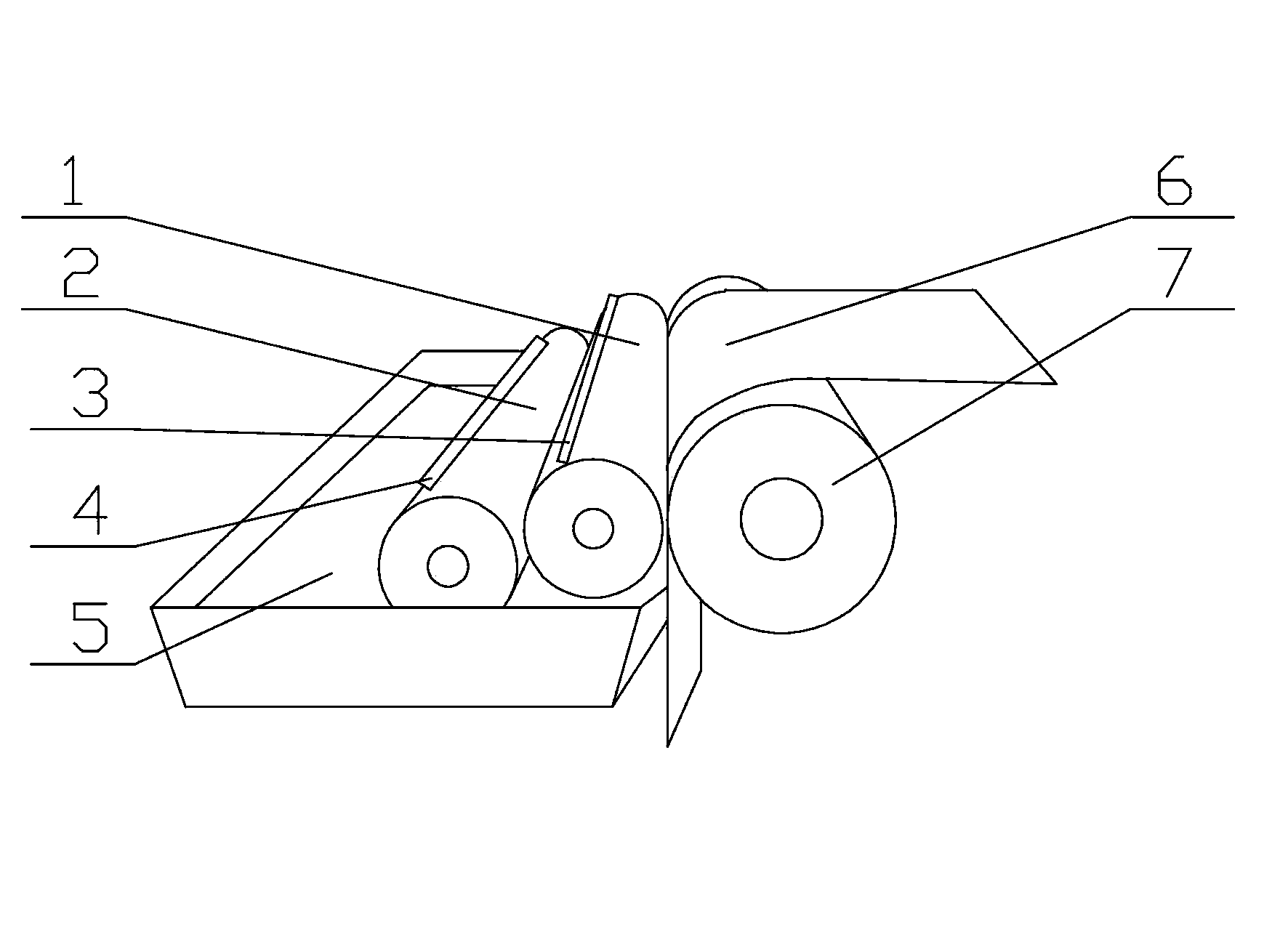

[0020] 1. Place the required pattern engraving knife on the suction roller, and the pattern is concave. For long patterns, due to the limited circumferential area of the suction roller, the pattern can be engraved on each group of suction rollers in turn;

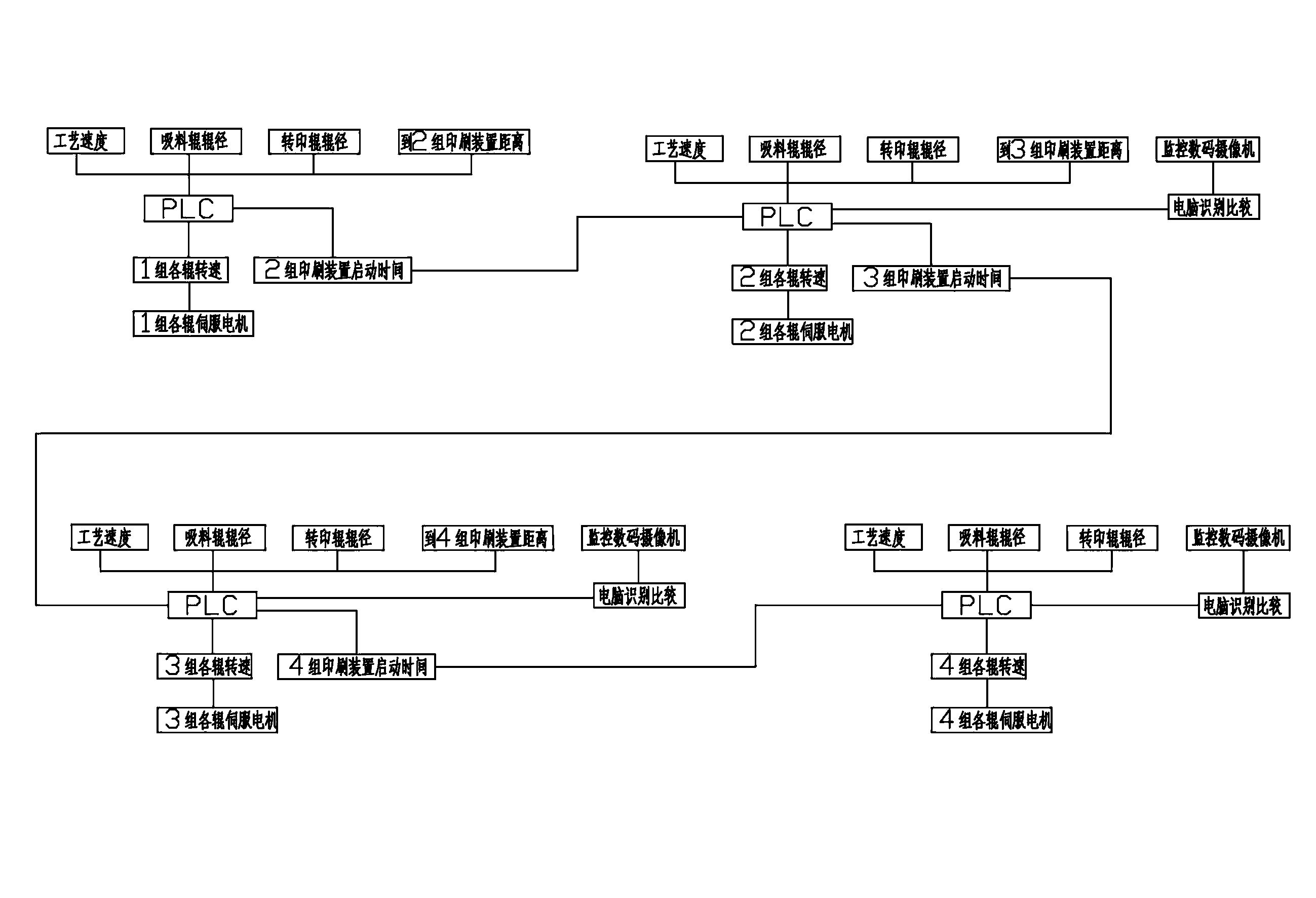

[0021] 2. Input the process speed of each group of printing devices, the diameter of the suction roller and the diameter of the transfer roller into the PLC controller of the corresponding group, so as to obtain the rotation speed of each roller of the group of printing machines, and start the first group of printing device, and simultaneously input the distance to the second group of printing devices to obtain the start-up time of the second group of printing devices;

[0022] 3. When the first group of steel plate patterns arrive at the second group of printing devices, it is exactly the start time of the second group of printing devices, the second group of printing devices st...

Embodiment 2

[0024] Embodiment 2: multi-color long

[0025] 1. When the desired pattern can be engraved on the circumference of a group of suction rollers, the patterns of each color can be engraved on different groups of suction rollers;

[0026] 2. Input the process speed of each group of printing devices, the diameter of the suction roller and the diameter of the transfer roller into the PLC controller of the corresponding group, so as to obtain the rotation speed of each roller of the printing machine in this group, and start the first group of printing device, and simultaneously input the distance to the second group of printing devices to obtain the start-up time of the second group of printing devices;

[0027] 3. When the first group of steel plate patterns arrive at the second group of printing devices, it is exactly the start time of the second group of printing devices, the second group of printing devices starts, and the patterns of the second group are just in the blank space ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com