A high-efficiency preparation process for the abrasive layer of a vitrified bond superhard material grinding wheel

A ceramic bond and superhard material technology, which is applied in the direction of manufacturing tools, grinding/polishing equipment, grinding devices, etc., can solve the problems of high labor input cost, poor process stability, and large labor load, so as to reduce the labor load , easy operation, and improved molding success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A high-efficiency preparation process for the abrasive layer of a vitrified bond superhard material grinding wheel, comprising the following steps:

[0022] (1) Pressing process: Using a horizontal overall mold, first adjust the size of the cavity, then put the mixed powder into the cavity, and finally the upper and lower heads are driven into the cavity at the same time by the press. The powder is moved and pressed, and the abrasive layer is formed by pressing at one time;

[0023] (2) Sintering: Use a sintering furnace to sinter the abrasive layer into an abrasive block; determine the temperature process curve according to different products, mainly consisting of a heating stage, a heat preservation stage, and a cooling stage.

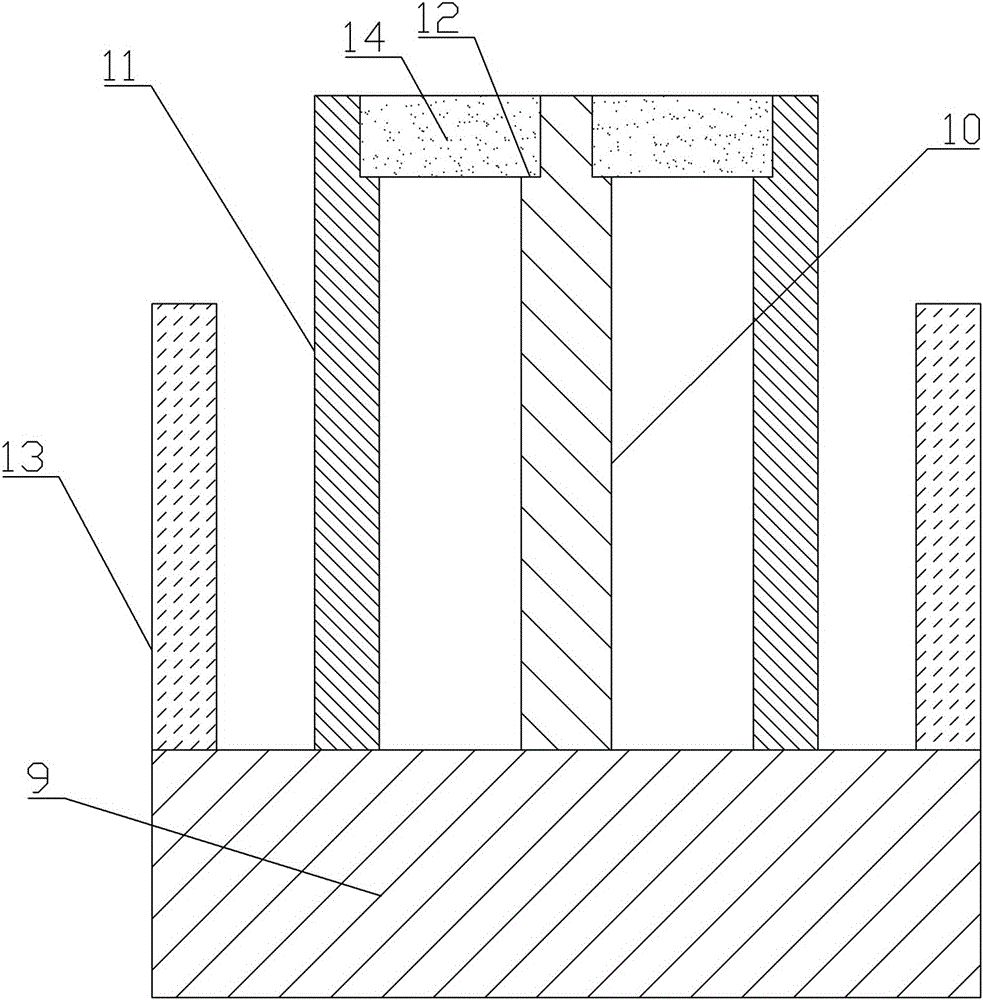

[0024] (3) Cutting: Place the abrasive block on a special fixture, and use laser cutting equipment to cut the abrasive block into abrasive layers for grinding wheels whose shape and size meet the requirements.

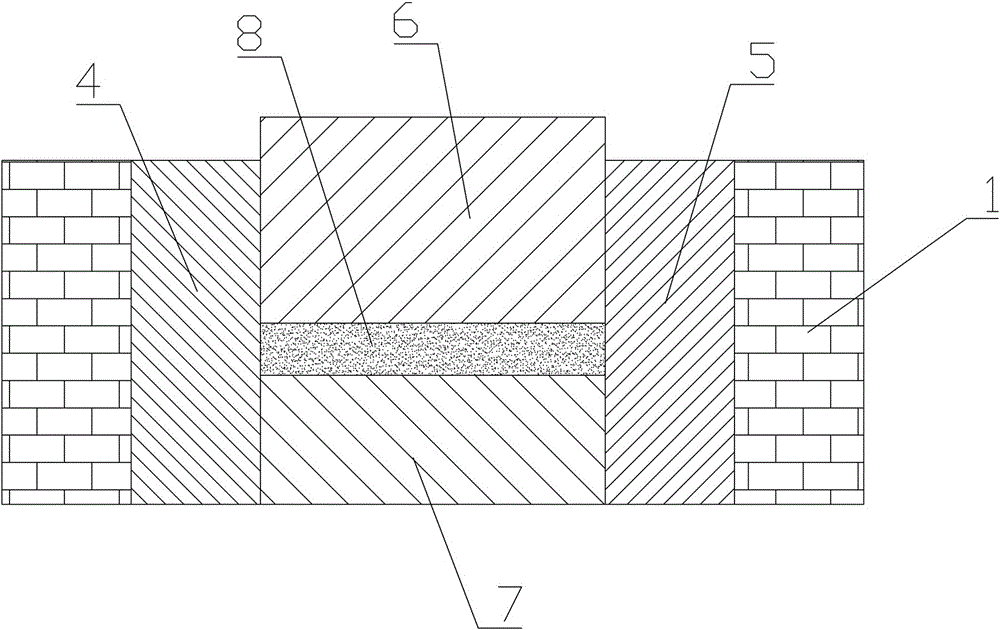

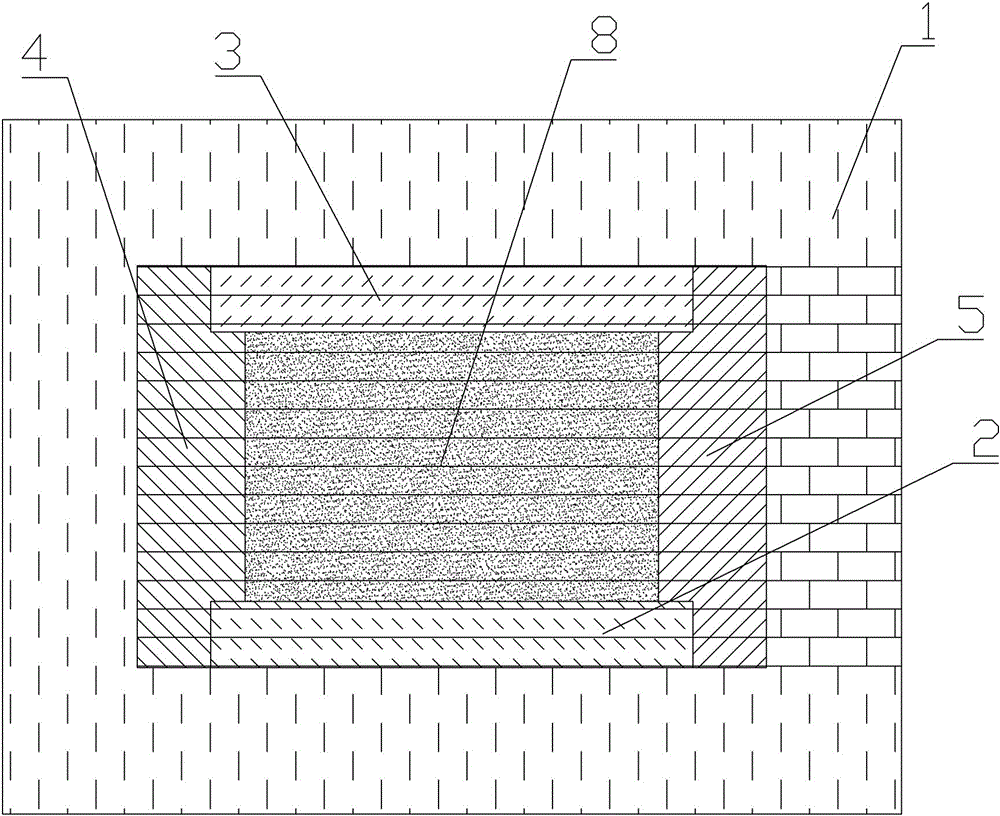

[0025] Such as figure 1 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com