Mechanical evaporator

An evaporator and mechanical technology, applied in evaporation, chemical instruments and methods, heating water/sewage treatment, etc., can solve the problems of low efficiency and achieve the effect of improving the evaporation process and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

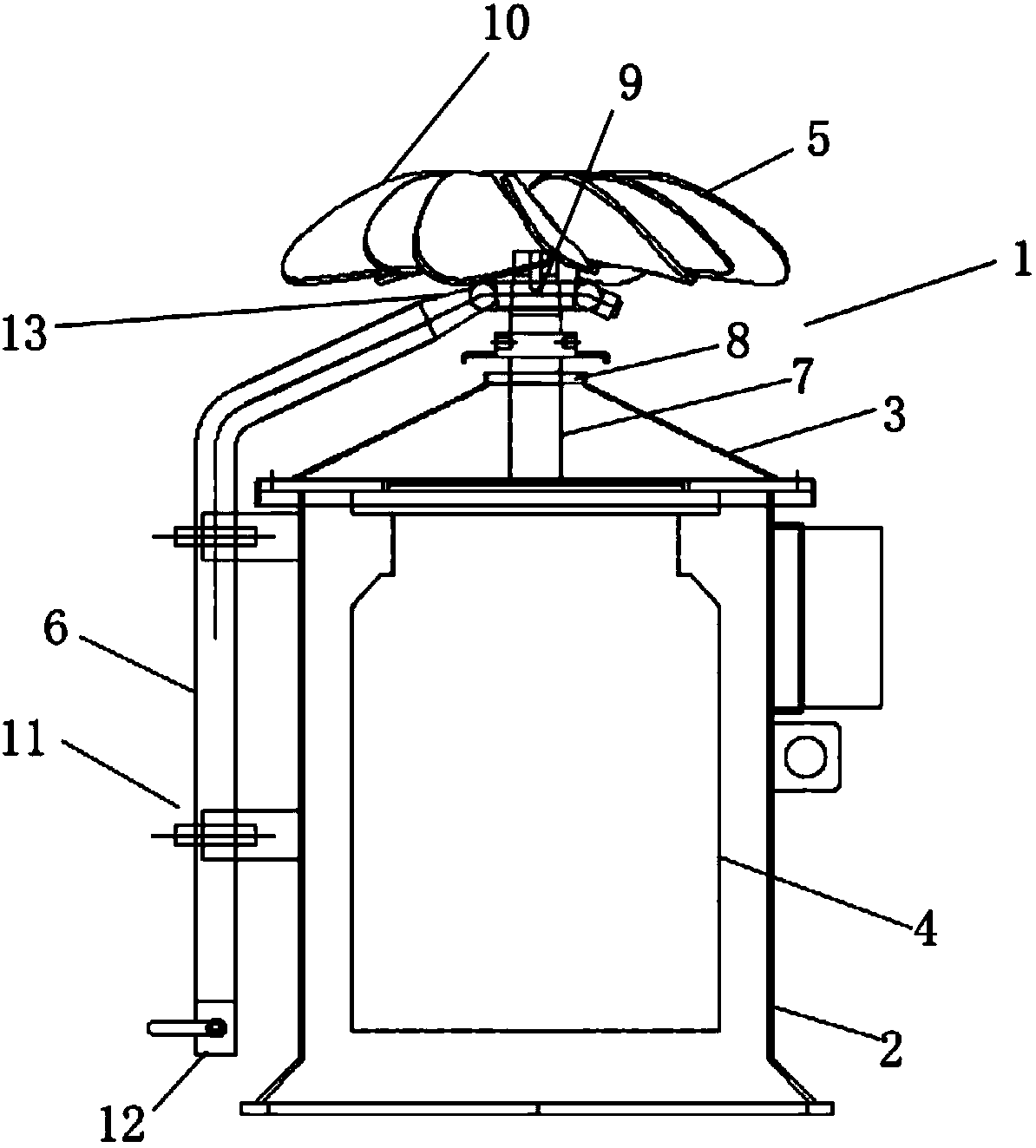

[0017] refer to figure 1 , a mechanical evaporator 1 of the present invention, which can be fixed on a bracket (not shown) for use, includes a casing 2, a top cover 3, a motor 4, an impeller device 5 and a water inlet device 6; the motor 4 includes a transmission shaft 7; the top cover 3 has an opening 8, and the top cover 3 is fixed on the casing 2; the impeller device 5 includes a hub 9 and a plurality of blades 10 fixed to the hub 9; the motor 4 passes through the top cover through a transmission shaft 7 3 to connect the hub 9 to drive the blade 10 to rotate, the water inlet device 6 includes a water inlet pipe 11, the water inlet pipe 11 includes a water inlet 12 and a water outlet 13, and the water outlet 13 is located below the blade 10.

[0018] During operation, the water inlet 12 supplies water to the water inlet pipe 11 through devices such as a submersible pump (not shown), and the water is sprayed upwards onto the blades 10 from the water outlet 13 of the water inl...

Embodiment 2

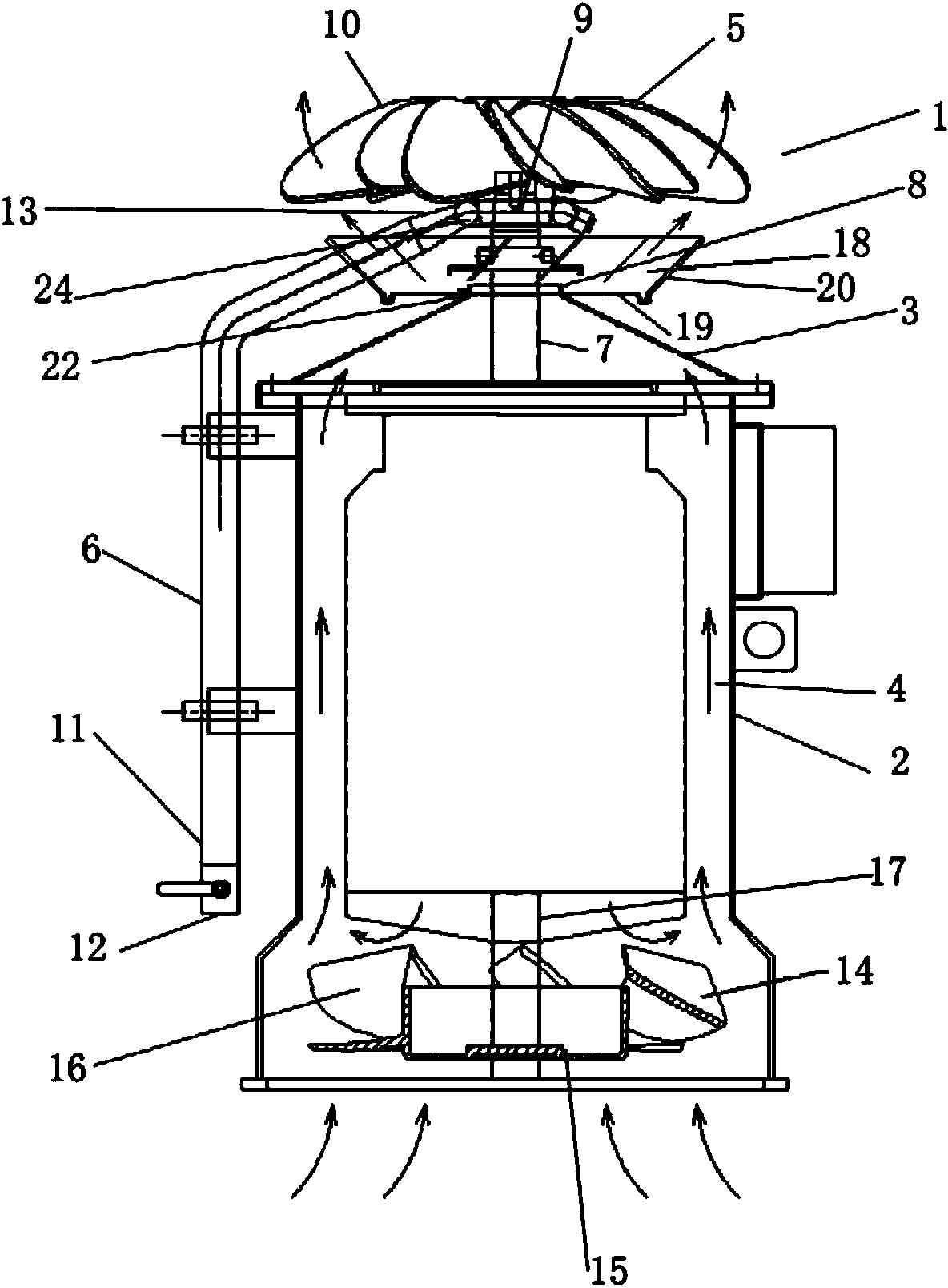

[0020] refer to Figure 2 to Figure 5 , a mechanical evaporator 1 of the present invention, which can be fixed on a bracket (not shown) for use, including a casing 2, a top cover 3, a double-headed motor 4, an impeller device 5 and a water inlet device 6; the double-headed motor 4 includes a transmission shaft 7 at one end and a transmission shaft 17 at the other end; the top cover 3 has an opening 8, and the top cover 8 is fixed on the casing 2; the impeller device 5 includes a hub 9 and a plurality of shafts fixed to the hub 9 The blade 10; the double-head motor 4 passes through the opening 8 of the top cover 3 through the transmission shaft 7 at one end and connects the hub 9 to drive the blade 10 to rotate. The water inlet device 6 includes a water inlet pipe 11, and the water inlet pipe 11 includes a water inlet 12 and The water outlet 13 is located under the blade 10 . The mechanical evaporator 1 includes a hurricane 14 arranged below the double-head motor 4; the openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com