Tracheotomy sleeve with double-layer air bags and preparation and use method thereof

A technology of tracheostomy cannula and double-layer airbag, which is applied in the field of medical clinical medical devices, and can solve problems such as cumbersome procedures, airway mucosal damage, and difficulty in determining the optimal value and variation of the operating pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

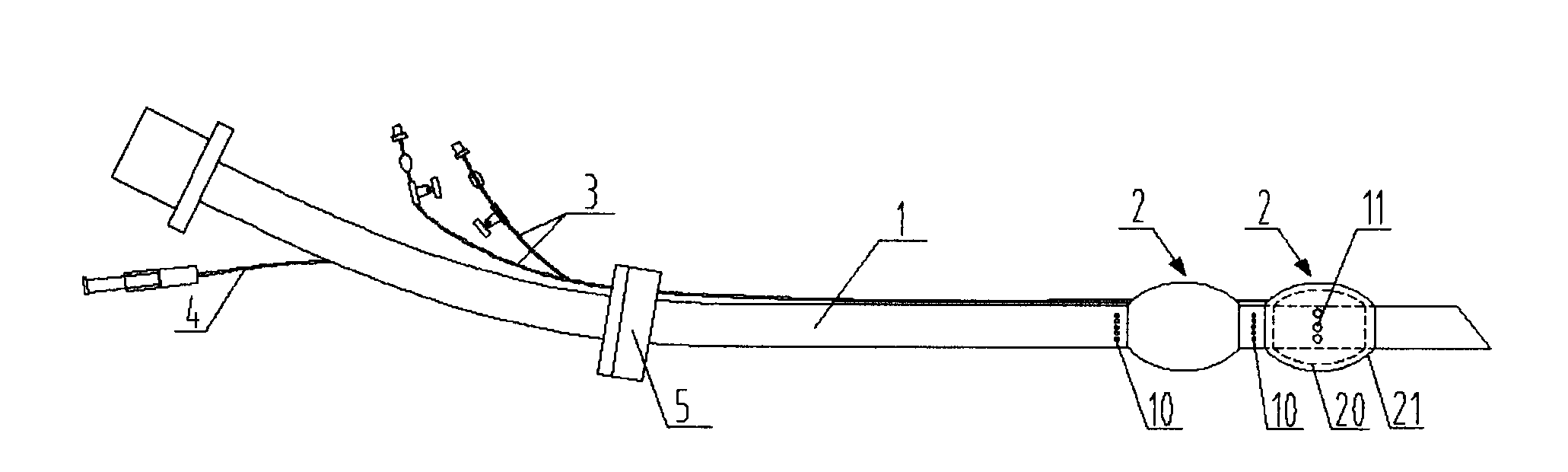

[0058] Embodiment one: figure 1 As shown, a double-layer balloon tracheotomy sleeve includes a cannula 1, and the insertion end of the cannula 1 is provided with two double-layer airbags 2 at intervals. The airbag 20 and the fixed airbag 21 outside the tube 1.

[0059] The safety airbag 20 and the intubation tube 1 are surrounded to form a safety air chamber, which communicates with the inner hole of the intubation tube 1 .

[0060] The fixed airbag 21 is surrounded by the intubation tube 1 and the safety airbag 20 to form a fixed air chamber, which is connected with the gas injection tube 3 .

[0061] Adjacent to the upper edge of the fixed balloon 21 , a set of suction holes is provided on the tube wall of the intubation tube 1 , consisting of 3 to 5 suction holes 10 on the back side of the cannula 1 . Wherein, 3 to 5 of the suction holes 10 are located on the same cross section, taking the dorsal line of the cannula as the center line, and radially distributed within 30° ...

Embodiment 2

[0091] Embodiment 2: Embodiment 2 of the present invention prepares such as by following method figure 1 For the double-layer balloon tracheostomy tube shown, the steps are as follows:

[0092] (1) 3000g medical-grade polyethylene, 60g zinc-based antibacterial agent, 90g aminoglycoside, 1200g diisononyl phthalate, 150g barium stearate, 90g rare earth stabilizer and 600g chlorinated polyethylene fat are mixed in proportion Mix evenly in a high-speed mixer to make composite materials;

[0093] (2) Put the composite material in a plastic extruder, extrude it at a temperature of 150-180° C. and cut it into pellets with a pelletizer to obtain medical antibacterial plastic pellets;

[0094] (3) Place the medical antibacterial plastic particles obtained in step (2) in the extruder, extrude the intubation tube, the gas injection tube and the suction tube with arc tube and straight tube by extrusion cooling method, then put the intubation tube One of the ends is wedge-shaped to form th...

Embodiment 3

[0116] Embodiment three: the embodiment three of the present invention prepares as follows through the following method figure 1 For the double-layer balloon tracheostomy tube shown, the steps are as follows:

[0117] (1) 3000g medical-grade silicone rubber, 150g copper-based antibacterial agent, 150g quinolones, 1500g diisononyl phthalate, 240g calcium stearate, 150g rare earth stabilizer and 900g chlorovinyl acetate are mixed at high speed in proportion Mix evenly in the mixer to make composite materials;

[0118] (2) Put the composite material in a plastic extruder, extrude it at a temperature of 150-180° C. and cut it into pellets with a pelletizer to obtain medical antibacterial plastic pellets;

[0119] (3) Place the medical antibacterial plastic particles obtained in step (2) in the extruder, extrude the intubation tube, the gas injection tube and the suction tube with arc tube and straight tube by extrusion cooling method, then put the intubation tube One of the ends...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com