Process for increasing milk yield of dairy cow by wet fermentation protein feed

A technology of fermented protein feed and milk production, applied in animal feed, animal feed, food processing, etc., can solve the problems of nutritional value loss, air pollution, high cost, etc., and achieve nutritional value improvement, fast digestion speed, and well-preserved Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

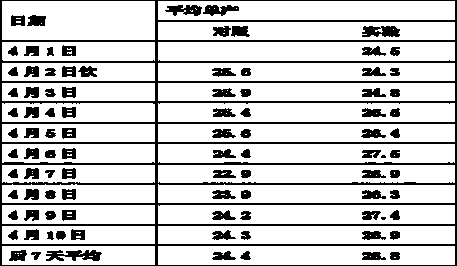

Image

Examples

Embodiment 1

[0031] The production of wet fermented protein feed is carried out in a wet feed processing plant. Mix the wet dregs of the distiller's tank with the distiller's dregs at a ratio of 1:1.2, then add 0.1% probiotics for fermentation, and put them in an airtight container (sealed plastic bag or barrel), with a shelf life of 6 months The above can fully meet the storage time required in production. If the feed is not used up at one time, the air in the packaging bag needs to be drained and sealed to prevent spoilage.

[0032] (2) Feeding wet fermented protein feed to dairy cows

[0033] 1. Feed amount: under the condition that the amount of conventional feed remains unchanged, each head is fed with 4 kg of biological protein feed per day;

[0034] 2. Feeding method: After feeding conventional feed and forage grass, in order to make each cow in the herd drink evenly the wet fermented protein feed, add the wet fermented protein feed into the drinking water in 4 times, every An av...

Embodiment 2

[0043] The production of wet fermented protein feed is carried out in a wet feed processing plant. Mix the wet dregs of the distiller's tank with the distiller's dregs at a ratio of 1:1.2, then add 0.1% probiotics for fermentation, and put them in an airtight container (sealed plastic bag or barrel), with a shelf life of 6 months The above can fully meet the storage time required in production. If the feed is not used up at one time, the air in the packaging bag needs to be drained and sealed to prevent spoilage.

[0044] (2) Feeding of dairy cows with wet fermented protein feed

[0045] 1. Feeding volume:

[0046] Under the condition that the amount of conventional feed remained unchanged, each cow was fed with 4kg wet fermented protein feed every day.

[0047] 2. Feeding method:

[0048] After feeding the conventional feed and forage grass, in order to make each cow in the herd drink the wet fermented protein feed evenly, add the wet fermented protein feed into the drink...

Embodiment 3

[0061] The production of wet fermented protein feed is carried out in a wet feed processing plant. Mix the wet dregs of the distiller's tank with the distiller's dregs at a ratio of 1:1.2, then add 0.1% probiotics for fermentation, and put them in an airtight container (sealed plastic bag or barrel), with a shelf life of 6 months The above can fully meet the storage time required in production. If the feed is not used up at one time, the air in the packaging bag needs to be drained and sealed to prevent spoilage.

[0062] (2) Feeding of dairy cows with wet fermented protein feed

[0063] 1. Feed amount of wet fermented protein feed: under the condition that the amount of conventional feed remains unchanged, feed 4 kg of biological protein feed per head per day;

[0064] 2. Feeding method of wet fermented protein feed: Wet fermented protein feed is easy to disperse and dissolve in water. Therefore, this experiment adopts the method of adding it to the drinking water of cows. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com