Residue discharge and heat recovery method of pyrite acid production and equipment system

A technology of heat recovery and pyrite, applied in lighting and heating equipment, preheating, waste heat treatment, etc., can solve the problems of environmental pollution, slag discharge heat recovery and utilization rate, etc., to maintain grade, save drying cost, Addressing the Effects of Recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

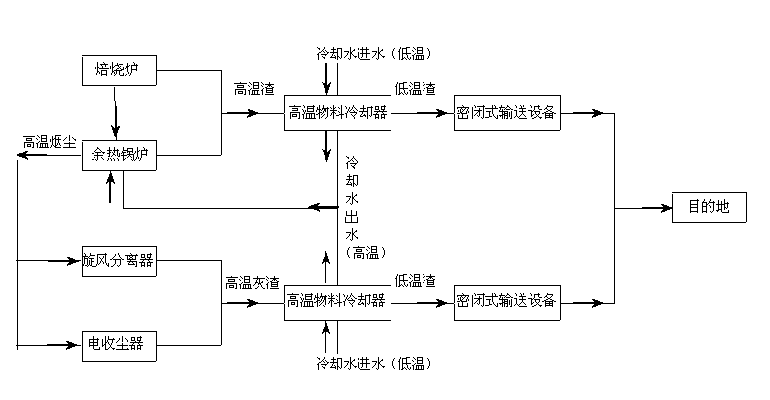

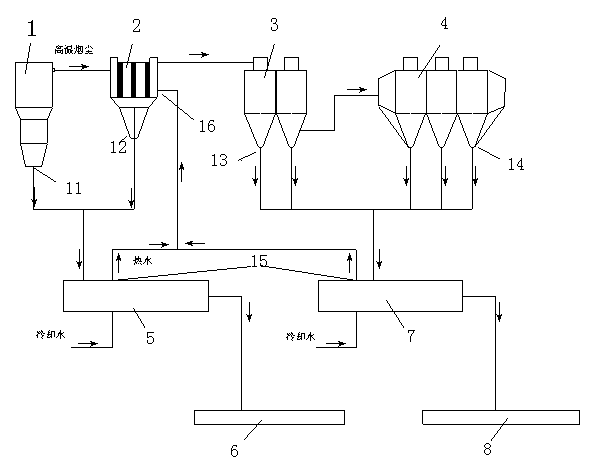

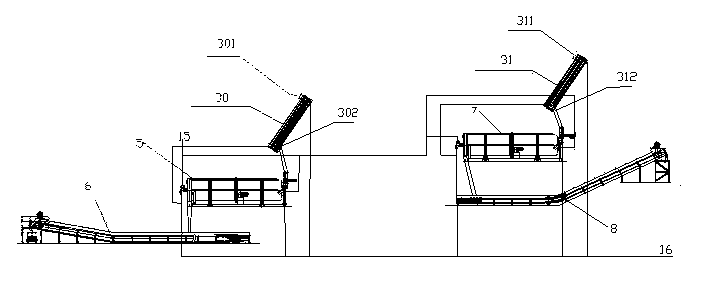

[0040] like figure 1 As shown, the preferred process of the present invention is as follows: the hot slag of the roasting furnace and the hot slag of the waste heat boiler merge into a high-temperature material cooler through the closed high-temperature material tank pipeline, and the 850°C- The high-temperature slag at 1100°C is cooled to 80°C-60°C and transported to the destination through a closed conveying device. The high-temperature dust-laden gas discharged from the roaster is first discharged through the waste heat boiler to recover part of the heat and collect dust. The dust-laden gas discharged from the waste heat boiler is collected again by the cyclone separator and the electric precipitator. The airtight conveying device transports to the destination. The cooling water is heated through indirect heat exchange in the two high-temperature material coolers. While the high-temperature ash is cooled to 80°C-60°C, the cooling water is raised from normal temperature 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com