A kind of production method of radial permanent magnet rotor of drive motor of electric van transport vehicle

A technology for driving motors and permanent magnet rotors, applied in the manufacture of stator/rotor bodies, etc., can solve problems such as power, torque reduction, irreversible demagnetization, and motor efficiency reduction, achieving low power consumption, compact structure, and reliable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

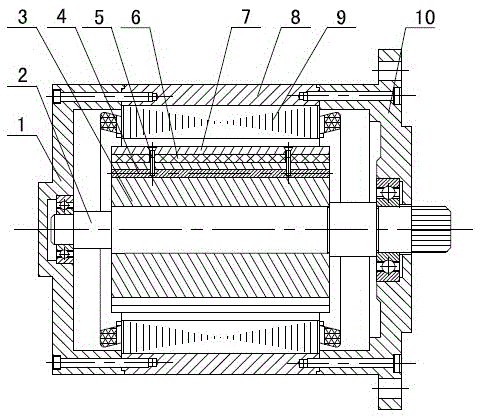

[0026] A method for producing a radial permanent magnet rotor for a drive motor of an electric van transport vehicle, comprising the following steps:

[0027] The central hole of the mounting shaft 2 is drilled in the center of the rotor punch, and an even number of rivet holes are evenly drilled on the upper circumference of the rotor punch, so that the distance between the outer end of the rivet hole and the outer circle of the rotor punch is 2mm;

[0028] A plurality of rotor punching sheets are laminated in a burr-sequence manner, and then riveted with iron rivets 4 to form a rotor core 3; the rotor punching sheets are laminated in a burr-sequence manner, which can effectively reduce the influence of burrs on magnetic performance.

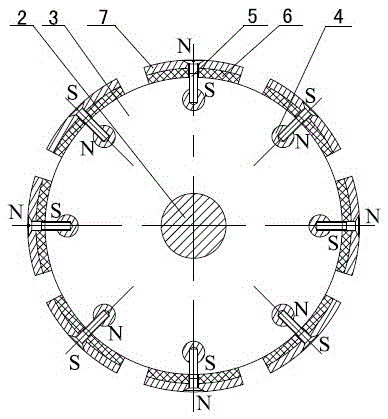

[0029] The tile permanent magnet steel 6 is fixed on the outer circle of the rotor core 3 by the screws 5 through the pole shoes 7 in such a way that the convex surface is N poles and S poles are arranged at intervals;

[0030] The rotor core 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com