An organic electroluminescent device

An electroluminescent device and luminescence technology, which is applied in the direction of electric solid devices, electrical components, semiconductor devices, etc., can solve the problems of difficult adjustment of viewing angle and low lifespan, and achieve the effects of excellent viewing angle, prolonging lifespan, and increasing the composite area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

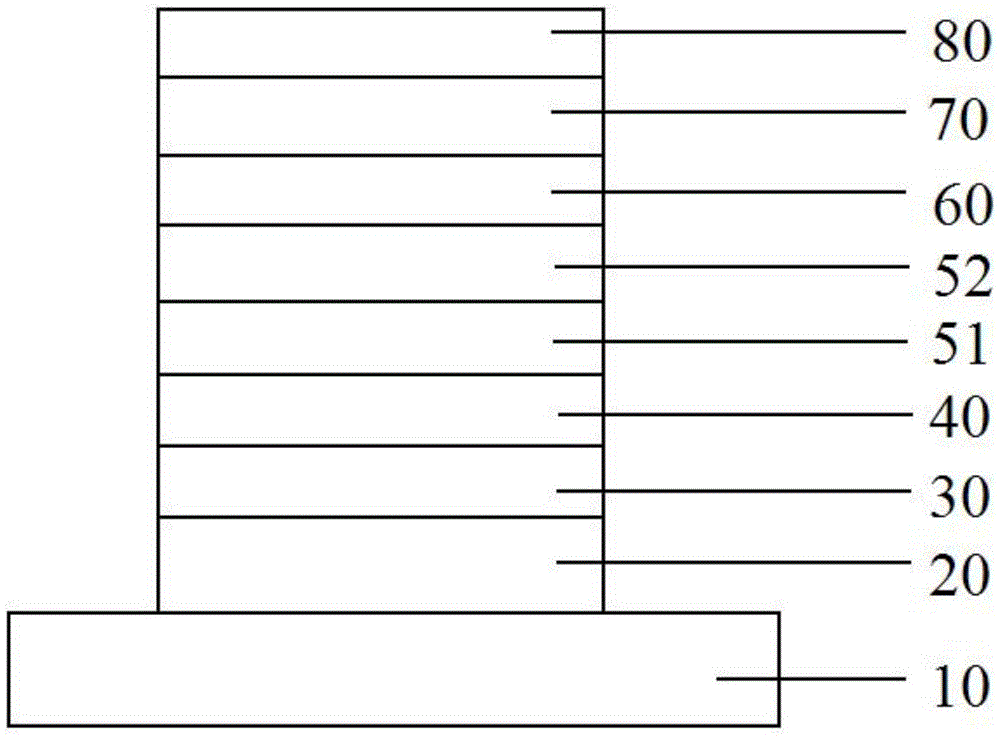

[0035] This embodiment provides an organic electroluminescent device, such as figure 1 As shown, the first electrode 20 , the blue light emitting layer and the second electrode 70 are sequentially stacked on the substrate 10 . The light emitting layer includes a first light emitting layer 51 and a second light emitting layer 52 stacked in sequence, and the first light emitting layer 51 is disposed close to the first electrode 20 . The first light-emitting layer 51 is a single hole-type host material-doped guest dye layer, the second light-emitting layer 52 is an electron-type host material-doped guest dye layer, and the thickness of the first light-emitting layer can be adjusted. The total thickness of the light emitting layer and the second light emitting layer is between 10nm and 40nm, wherein the thickness of the first light emitting layer is 1nm to 25nm.

[0036] The substrate 10 is selected from, but not limited to, a glass substrate and a polymer substrate. In this embo...

Embodiment 2

[0064] This embodiment provides an organic electroluminescent device, such as figure 1 As shown, the specific structure and preparation method are the same as those in Example 1, the only difference is that the second light-emitting layer 52 also includes the hole-type host material NPB.

[0065] In this embodiment, the HOMO energy levels of the hole-type host material and the electron-type host material are respectively 5.4 eV and 5.9 eV, and the absolute value of the difference is greater than 0.2 eV. In order to facilitate carrier recombination and reduce device voltage, the second light-emitting layer 52 adopts a double-carrier mixed structure. As another embodiment of the present invention, when the absolute value of the highest occupied orbital (HOMO) energy level difference between the host material in the first light-emitting layer and the host material in the second light-emitting layer is greater than 0.2eV, The second light-emitting layer 52 also includes a hole-ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com