Improved structure of light emitting sub-module

A light emission sub-module and improved structure technology, applied in the direction of light guides, optics, optical components, etc., can solve problems such as the influence of optical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

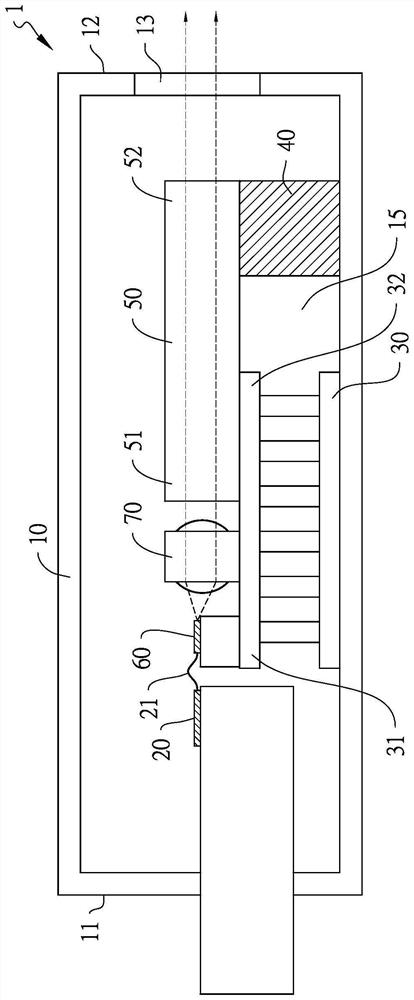

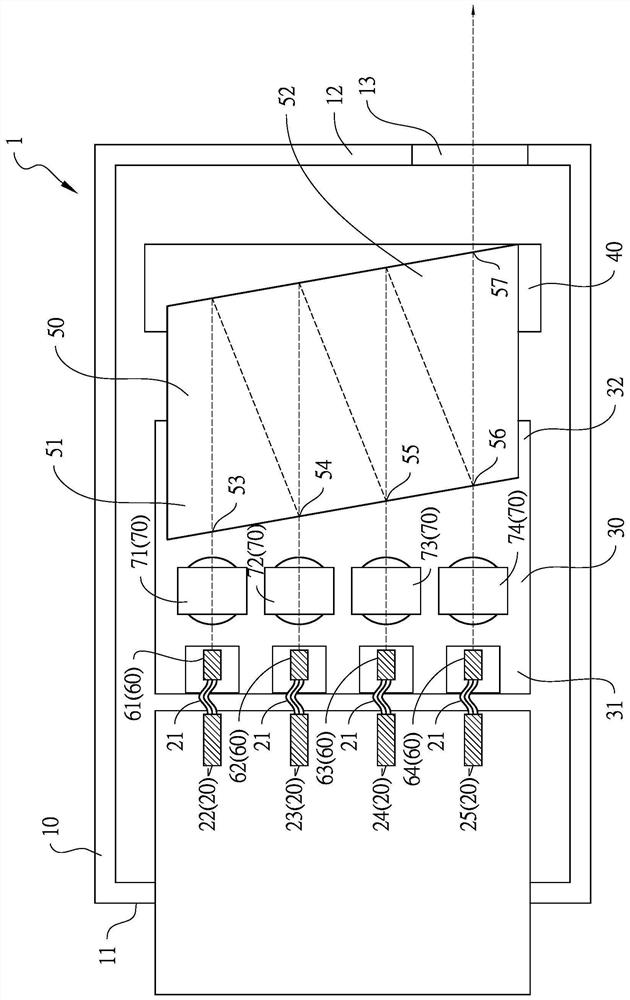

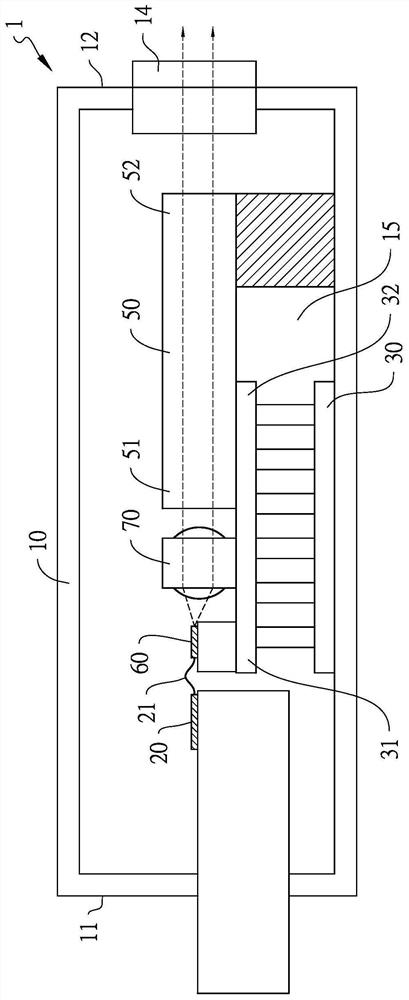

[0035] see Figure 1A , which is a schematic cross-sectional view of a specific embodiment of an improved structure of a light emitting sub-module of the present invention. Please also see Figure 1B , which is Figure 1A A schematic top view of an embodiment. The improved structure 1 of a light emitting sub-module of the present invention includes: a packaging box 10, a laser diode driver group 20, a flexible circuit board 21, an electrothermal cooling chip 30 (TEC: thermoelectric cooler), an optical engineer The support column 40 , an optical multiplexer 50 , a laser diode group 60 , and a collimator lens group 70 . Wherein the packaging box 10 is made of metal. The packaging box 10 has a circuit control terminal 11 and a light emitting terminal 12 . The light emitting end 12 has a light emitting hole 13 . The laser diode driver group 20 is disposed on the circuit control terminal 11 . The laser diode driver group 20 includes four laser diode drivers 22 , 23 , 24 , 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com