Liquid crystal display device

A technology of liquid crystal display and liquid crystal display panel, applied in static indicators, instruments, optics, etc., can solve problems such as poor heat dissipation of backlight components, and achieve the effect of improving poor heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

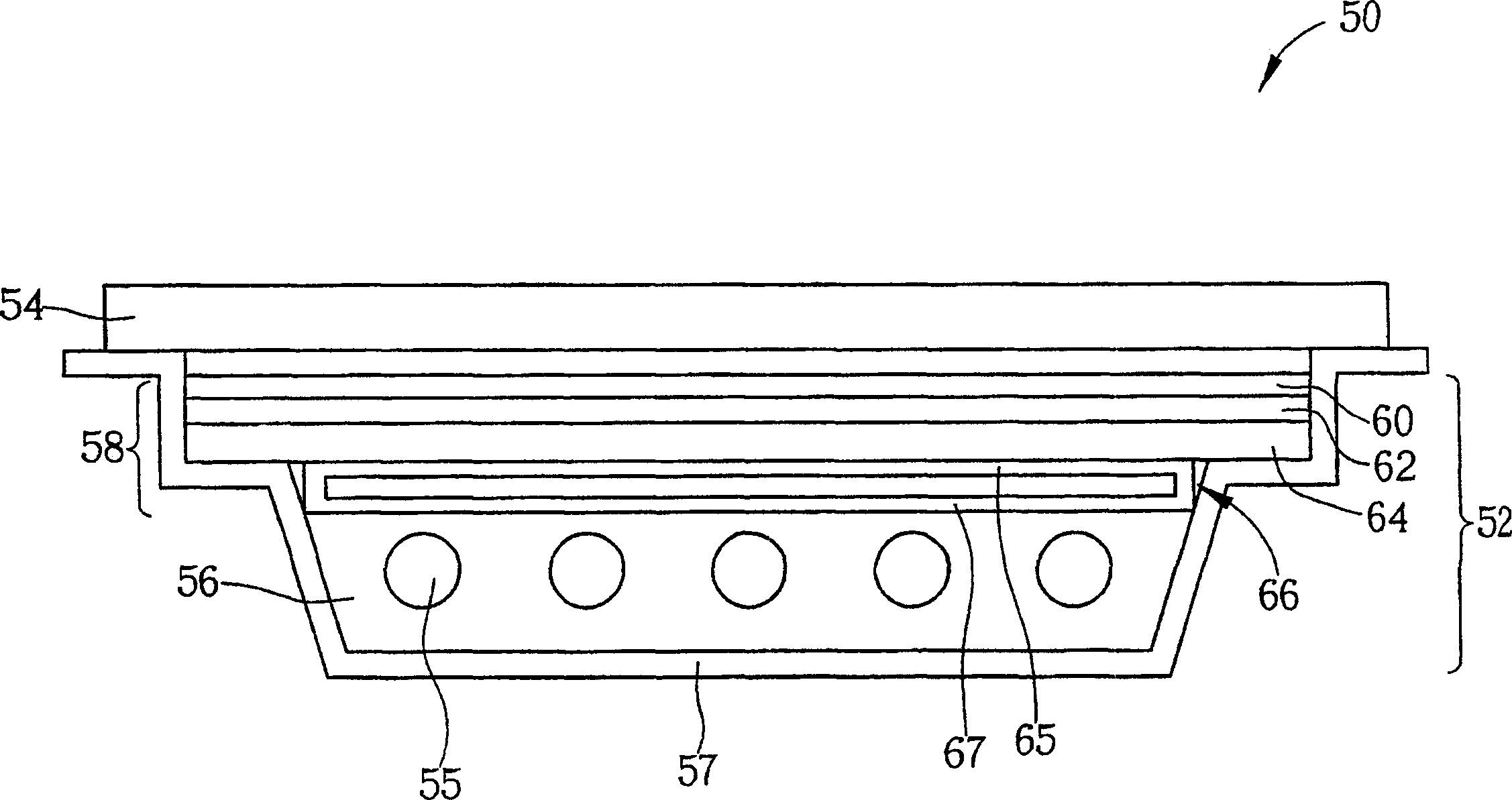

[0011] refer to figure 2 , figure 2 It is a schematic structural diagram of the liquid crystal display 50 in the first embodiment of the present invention. Such as figure 2 As shown, the liquid crystal display 50 includes a backlight assembly 52 and a liquid crystal display panel 54 . The backlight assembly 52 includes an optical film 58 disposed above a light source 56, wherein the light emitting element forming the light source 56 can be a cold cathode tube (Cold Cathode Fluorescent Light, CCFL), a hot cathode lamp, or a cold cathode lamp with external electrodes. Or cold cathode flat fluorescence lamp (cold cathode flatfluorescence lamp, CCFFL). The liquid crystal display panel 54 includes a plurality of pixel units (not shown) and is disposed above the optical film 58 . In addition, a reflective plate 57 is disposed under the light source 56 for reflecting the light generated by the light source 56 upwards, so as to provide better brightness output of the liquid cry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com