Complete redundancy testing apparatus control system of direct-current valve cooling unit

A test device and control system technology, applied in the field of complete redundant test device control system, can solve problems such as large economic losses and affect the stable operation of a DC valve cooling system, improve redundancy, and improve system refusal and malfunction , the effect of improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

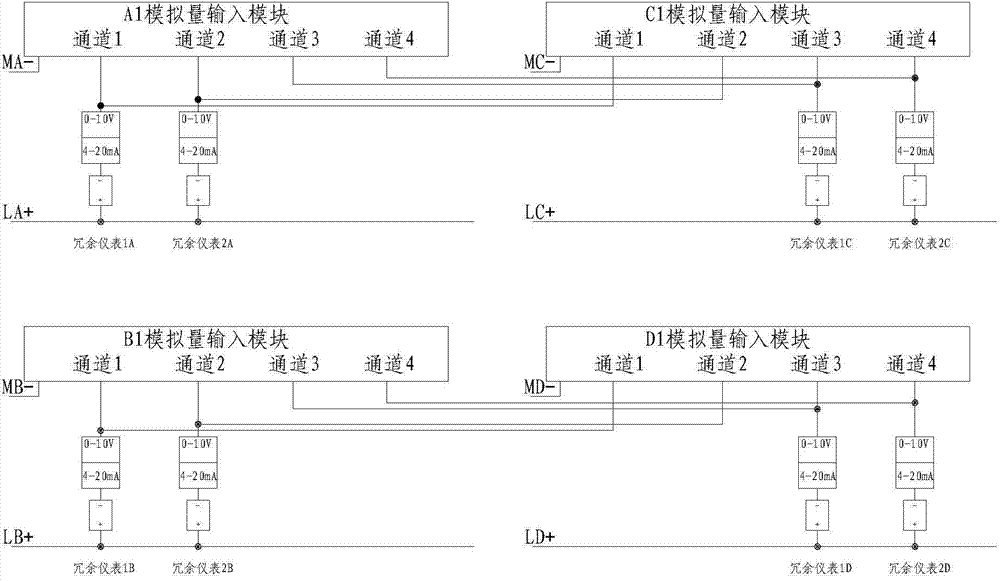

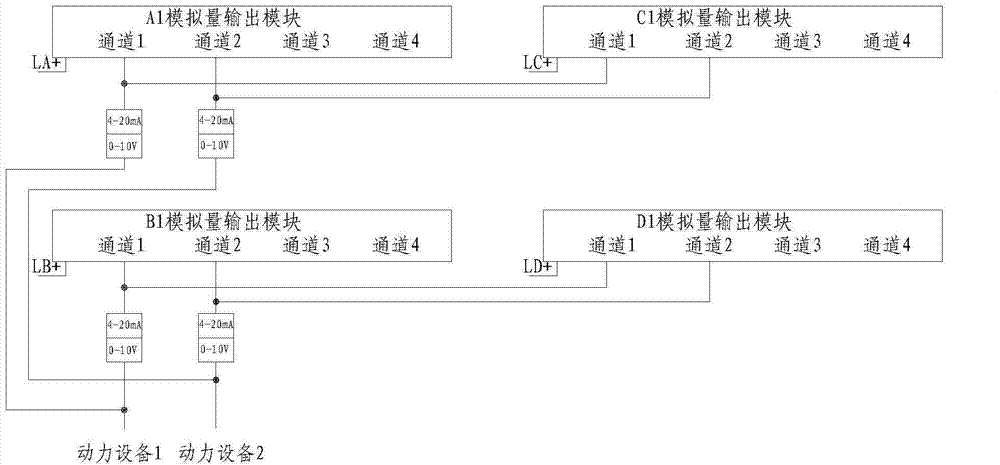

[0036] Such as figure 2 As shown, the control system of the DC valve cooling complete redundant test device includes:

[0037] (1) Redundant programmable logic controllers: PLC A and PLC B respectively, used to coordinate and process various data, and issue corresponding instructions;

[0038] (2) Redundant input / output modules: there are four sets of input / output modules, the input / output modules include digital input modules A, B, C and D, digital output modules A, B, C and D, analog Quantity input modules A, B, C, and D, and analog output modules A, B, C, and D are used to transfer input signals to PLCs and transfer output signals of PLCs to corresponding electromechanical equipment , the digital input modules A and B, digital output modules A and B, analog input modules A and B, analog output modules A and B, programmable logic controller A set and control cabinet A, the digital Quantity input module C and D, digital quantity output module C and D, analog quantity input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com