Leadless packaging structure and SOI absolute pressure sensitive device of leadless packaging structure

A packaging structure and sensitive device technology, which is applied in fluid pressure measurement by changing ohmic resistance, electric solid devices, semiconductor devices, etc., can solve problems such as the influence of absolute pressure sensitive devices, electrode system debonding failure, and easy leakage of silicone oil. Achieve strong overload resistance, excellent thermal conductivity, and improve the effect of electrical insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

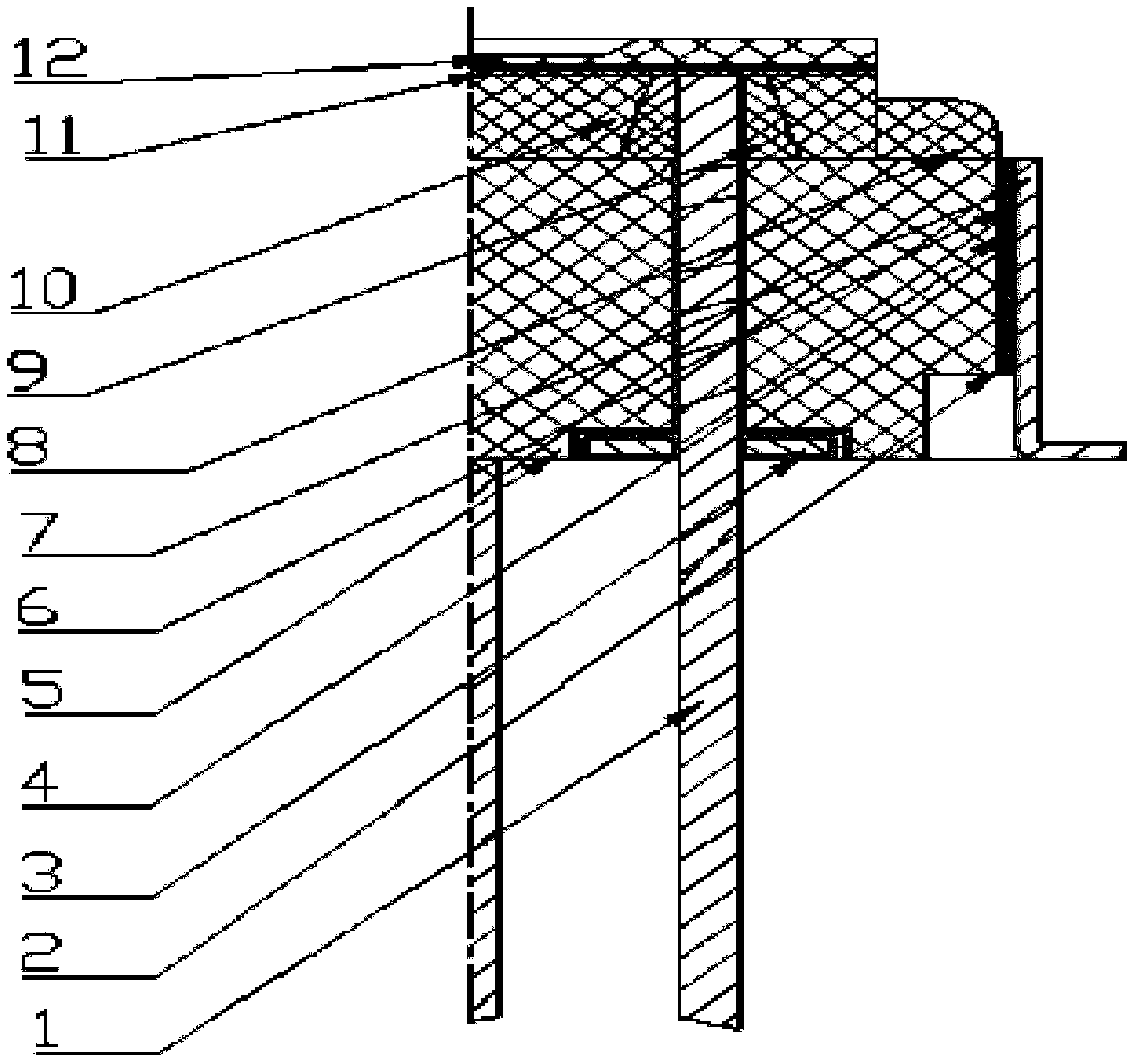

[0011] Embodiment 1: A leadless packaging structure, which is characterized in that it uses a solid insulating material, sinters the metallization layer on the surface of the solid insulating material at a high temperature, and uses nickel or Ag-Cu solder as a transition material to sinter with the metal shell to form a seal structure.

specific Embodiment approach 2

[0012] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the solid insulating material is Al 2 o 3 , SiC, BeO, TiO 2 , ZrO 2 , MgO, AlN, Si 3 N 4 Or BN and mixtures of all the above materials. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0013] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: the material of the metallization layer includes tungsten or molybdenum and a mixture of all the above materials. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com