Novel road and construction method thereof

A construction method and road technology, which is applied to roads, roads, on-site paved concrete pavements, etc., can solve the problems of high cost and slow construction progress, and achieve the effects of accelerating construction, reducing material waste, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

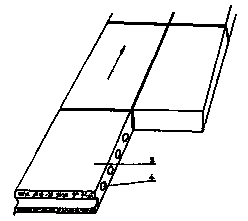

[0044] Embodiment 1: see Fig.], 2,9 0

[0045] A new type of road, which consists of a pavement compacted base 1, poured on the pavement compacted base 1, with a thickness of 220 mm and a single row of holes 4 inside (the diameter of the holes is about 100 mm. The distance between the holes is 1.3-1.5 times the diameter) The hollow concrete layer 2 is composed of;

[0046] The hollow concrete layer 2 is composed of cementitious materials (70% (weight%, the same below) slag, 15% converter steel slag, 10% admixture (including 2% quicklime, 8% cement clinker), 5% activator (including 2% aluminum mud, 3% Glauber's salt ore) mixed and ground to fineness (passed through O.08 mm square hole sieve), less than 2% composition), 1mm steel slag (or coarse sand), crushed stone, water press The ratio of the prior art is mixed, the single row of holes is molded and cast directly, and the 28-day compressive strength is greater than 40MPa, and the flexural strength is greater than 8Mpa....

Embodiment 3

[0050] Embodiment 3: see Figure 6 , 9 .

[0051] A new type of road, the base layer 1 is compacted from the road surface, poured on the compacted base layer 1 of the road surface, the thickness is 300 mm, and there are double rows of holes 4 and small holes 8 (the diameter of the large hole is about 80-120 mm, and the diameter of the small hole 8 It is composed of hollow concrete layer 2 of 50-80mm and 1;

[0052] The hollow concrete layer 2 is composed of cementitious materials (5.8% slag, 1.0% electric furnace steel slag, 1.5% phosphorus slag, 10% admixture (including 2% quicklime, 8% cement clinker), 7% activator ( Containing 1% aluminum mud, 4% Glauber's salt ore, 2% calcined alum ore) mixed and ground to a fineness (passed through a 0.08mm square hole sieve) less than 2% composition), less than 1mm steel slag (or coarse sand), Gravel and water are mixed according to the proportion of the existing technology, and the double rows of holes are molded and cast dire...

Embodiment 4

[0053] Embodiment 4: see Figure 8 , 1 0.

[0054] A new type of road, comprising pavement compacted base 1, prefabricated concrete hollow slabs 5 (each slab length can be 2500-3500 mm, width can be 900-1500 mm, thickness can be 1 20-180 mm) of the prefabricated concrete hollow slab, and the concrete surface layer 6 with a thickness of 60-120 mm poured on the prefabricated concrete hollow slab; and the total thickness of the prefabricated concrete hollow slab and the concrete surface 2 0-300mm;

[0055] The prefabricated concrete hollow slab 5 is prepared in the factory: take cementitious material (made of 43% slag, 20% fly ash, 20% phosphorus slag, 9% admixture (containing 3% quicklime, 6% cement clinker), 8 % activator (containing 2% aluminum mud, 2% calcined alunite ore, 4% glauberite ore) mixed and ground until the fineness is less than 2%), medium sand, crushed stone, water are mixed according to the existing technology ratio, after It is molded and cured. Eac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com