Device and method for detecting double parts

一种复式、零件的技术,应用在用于探测复式零件和装置领域,达到改善工艺可靠性、可靠控制的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

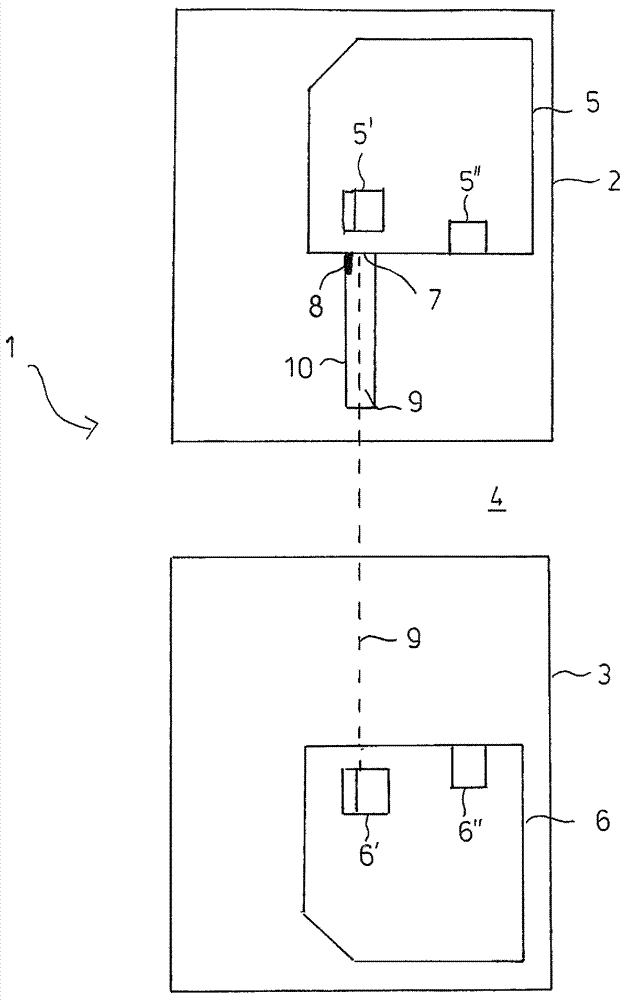

[0023] The drawing shows a device 1 with a first laser sensor unit 2 and a second laser sensor unit 3 . A measuring gap 4 is formed between the laser sensor units 2 , 3 . Each laser sensor unit 2 , 3 has a laser sensor 5 or 6 , which respectively contains a laser source 5 ′, 6 ′ and a detector 5 ″, 6 ″ for distance measurement in a known manner. The signal provided by the laser detector is evaluated by means of a control unit (not shown). On the laser sensor 5 there is a sleeve 10 for shielding from external light, which has a photoelectric receiver 8 on the inside at its end close to the exit window 7 of the laser sensor 5 . The photoreceiver 8 can be an ordinary photodiode. The photodiode detects light from a laser beam 9 originating from a laser source 6 ′ arranged in the laser sensor 6 as scattered light reflected back by the exit window 7 . The signal provided by the photodiode 8 is likewise fed to a not shown electrical control unit for evaluation.

[0024] The absen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com