Dedusting delivery system and method for bulk materials

A technology for bulk materials and conveying systems, applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of secondary dust, poor effect, low processing air volume, etc., and achieve the effect of reducing dust and preventing spontaneous combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

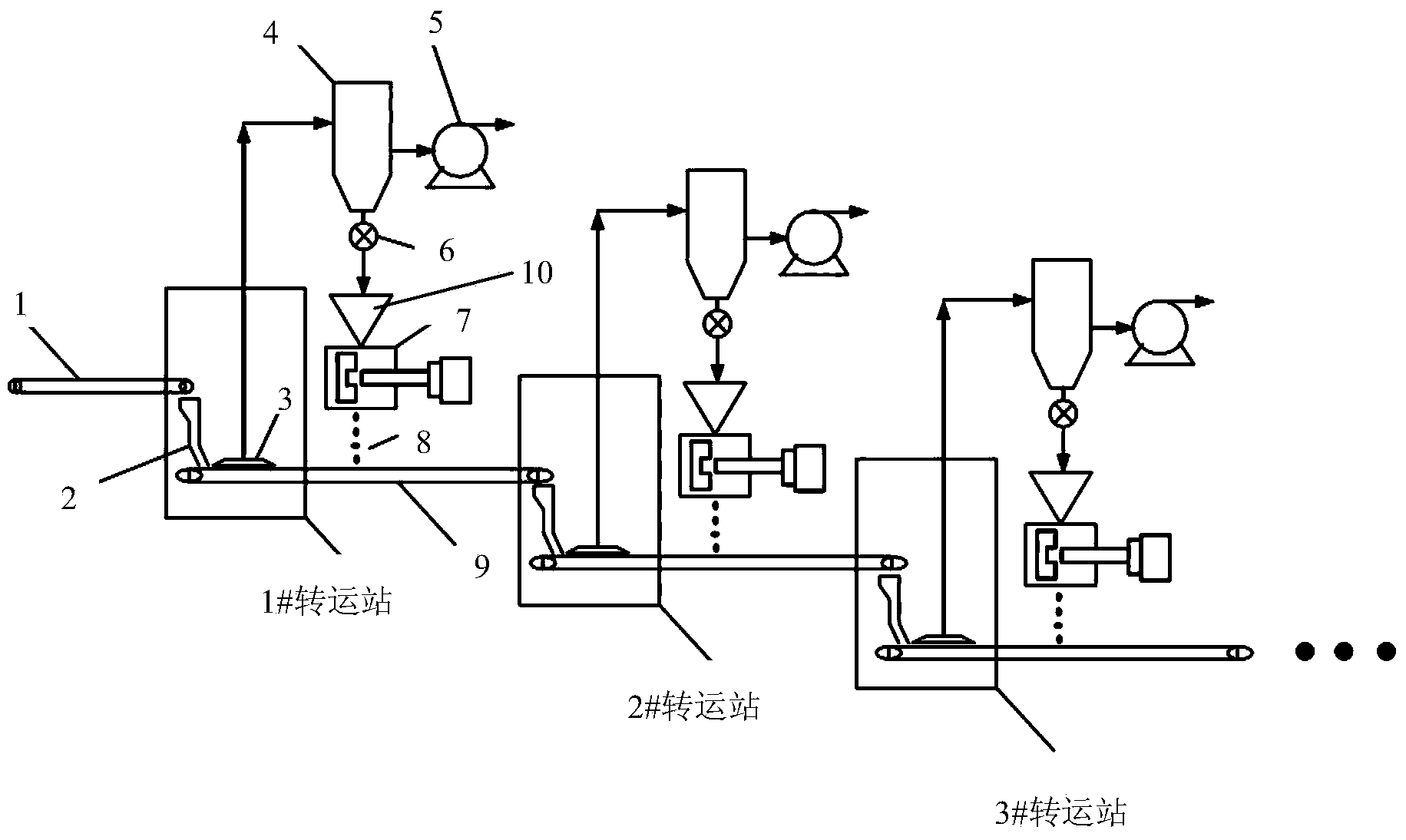

[0068] 1. The dried lignite is sent to the 1# transfer station through the closed first conveyor 1, and falls on the closed second conveyor 9 through the blanking pipe 2.

[0069] 2. The pulverized coal raised at the outlet of the discharge pipe 2 enters the pulse bag filter from the dust collection hood 3 along with the negative pressure gas generated by the induced draft fan 5 .

[0070] 3. The collected coal powder falls into the hopper at the bottom of the bag filter, and the purified gas is discharged from the induced draft fan 5.

[0071] 4. The pulverized coal falling into the hopper at the bottom of the bag filter enters the upper buffer bin 10 of the molding machine 7 through the discharger 6, and the molding machine 7 presses the pulverized coal into a briquette 8 with a certain shape and strength.

[0072] 5. The compressed coal 8 directly falls on the second conveyor 9 and is sent to the next transfer station or coal yard.

example 2

[0074] 1. The dried lignite is sent to the 1# transfer station through the closed first conveyor 1, and falls on the closed second conveyor 9 through the blanking pipe 2.

[0075] 2. The pulverized coal raised at the outlet of the discharge pipe 2 enters the pulse bag filter from the dust collection hood 3 along with the negative pressure gas generated by the induced draft fan 5 .

[0076] 3. The collected coal powder falls into the hopper at the bottom of the bag filter, and the purified gas is discharged from the induced draft fan 5.

[0077] 4. The pulverized coal falling into the hopper at the bottom of the bag filter enters the upper buffer bin 10 of the molding machine 7 through the discharger 6, and the molding machine 7 presses the pulverized coal into a briquette 8 with a certain shape and strength.

[0078] 5. The briquettes 8 pressed at the 1# transfer station, the briquettes 8 pressed at the 2# transfer station and other transfer stations are sent to the coal yard ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com