rear trailing arm

A technology of rear trailing arm and body, which is applied to the cantilever mounted on the pivot, suspension, transportation and packaging, etc., can solve the problems of complex structure of the rear trailing arm, simplify the structure and processing procedures, and reduce welding deformation. The effect of improving the positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

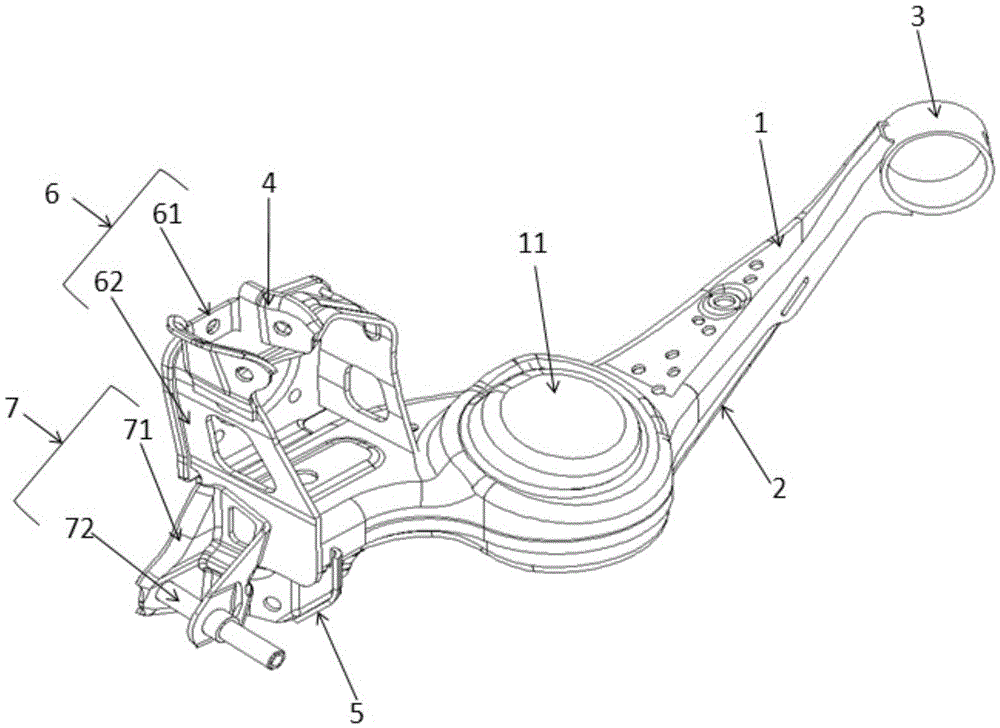

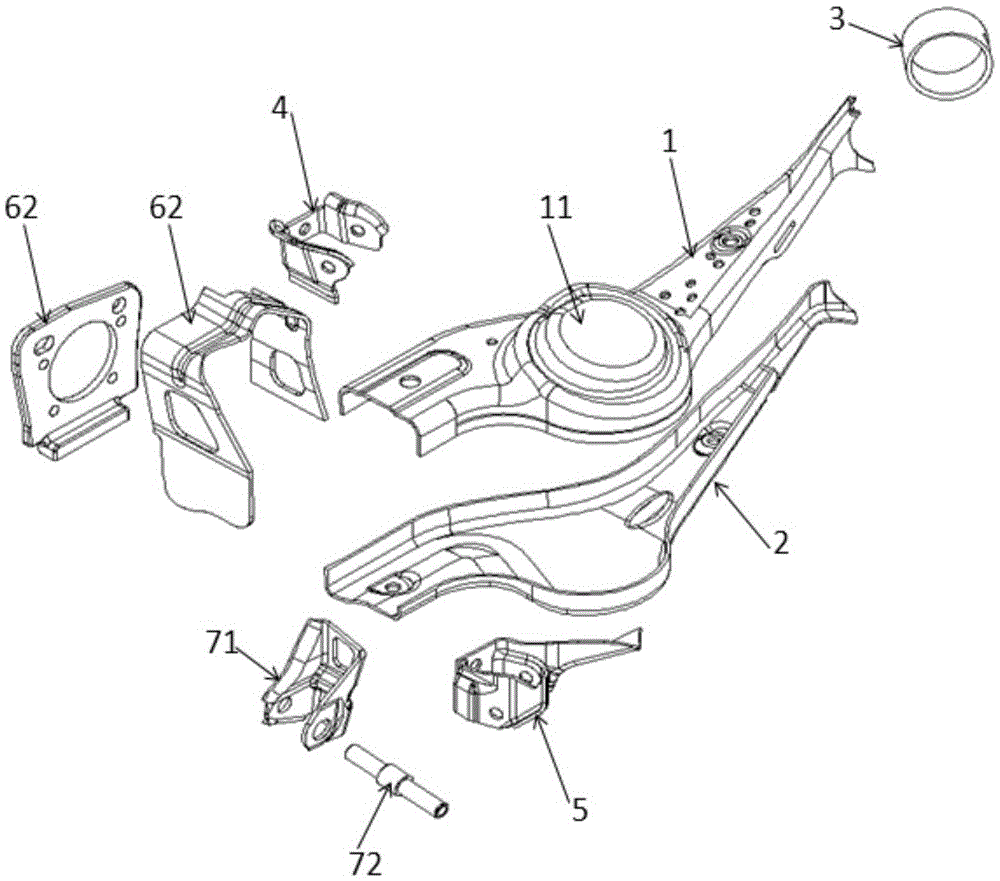

[0040] as attached figure 1 As shown, the embodiment of the present invention provides a rear trailing arm, including: upper body 1, lower body 2, bushing 3, upper swing arm connection seat 4, lower swing arm connection seat 5, brake mounting platform 6 and shock absorber mounting table 7,

[0041] Both the upper body 1 and the lower body 2 are stamped and formed by a single-layer steel plate;

[0042] The middle part of the upper body 1 is provided with a convex circular platform 11 upwards, the upper body 1 and the lower body 2 cooperate to form a cavity, and the two ends of the cavity are respectively a first end and a second end ;

[0043] The sleeve 3 is arranged at the first end of the cavity;

[0044] The brake mounting table 6 is arranged at the second end of the cavity;

[0045] The upper swing arm connecting seat 4 is arranged on the upper part of the brake mounting table 6;

[0046] The lower swing arm connecting seat 5 is arranged at the lower part of the seco...

Embodiment 2

[0070] The embodiment of the present invention provides a rear trailing arm, which includes: an upper body 1, a lower body 2, a bushing 3, an upper swing arm connection seat 4, a lower swing arm connection seat 5, a brake mounting platform 6, a Vibrator mounting table 7;

[0071] Wherein, both the upper body 1 and the lower body 2 are stamped and formed by single-layer steel plates, and cooperate with each other to form a square cavity support structure, and the middle part of the upper body 1 is provided with a convex round table with guiding threads facing upwards. 11;

[0072] The casing 3 is arranged at the first end of the cavity, and the first end is set in a rock axially concave shape, so as to facilitate the fixing of the casing 3;

[0073] The brake mounting table 6 is arranged at the second end of the cavity,

[0074] Specifically, the brake mounting table 6 includes: a brake mounting outer plate and a brake mounting inner plate, and the brake mounting outer plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com