Preparation method of wood-plastic composite material for doors and windows

A wood-plastic composite material, door and window technology, applied in the field of door and window manufacturing, can solve problems such as high cost, environmental pollution, unfavorable ecological environmental protection, etc., and achieve the effects of improving strength and toughness, reducing environmental pollution, and being beneficial to ecological and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

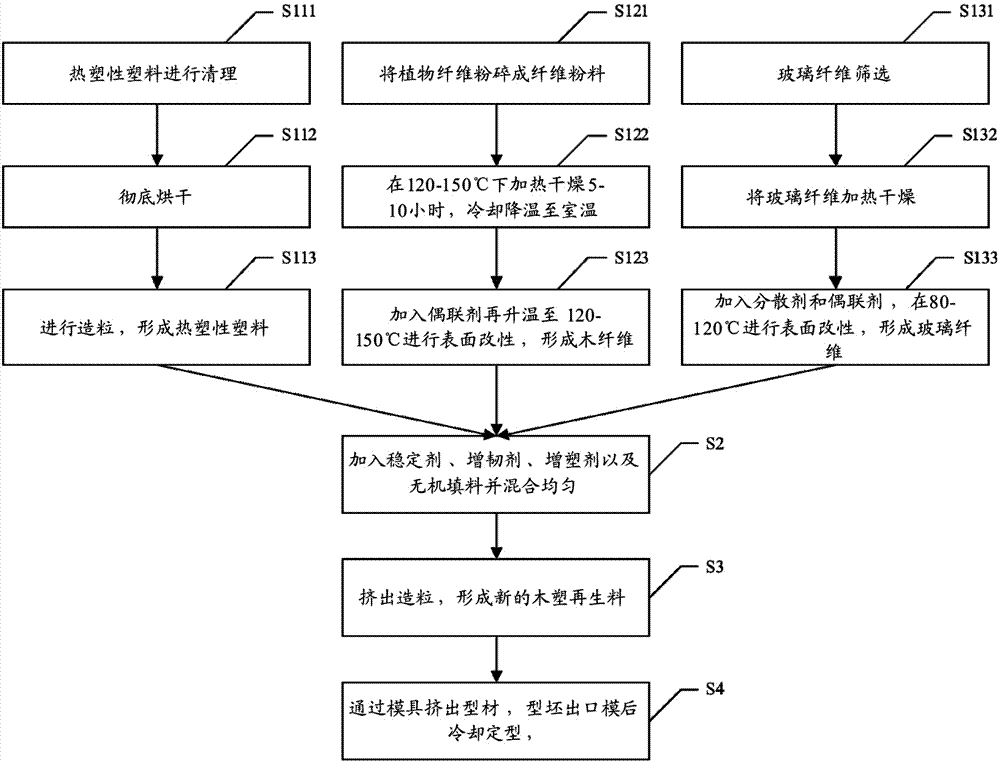

[0019] The preparation method of the wood-plastic composite material used for doors and windows in this embodiment comprises the following steps:

[0020] Step S1, crushing plant fibers into fiber powder, heating and drying at 120-150°C for 5-10 hours, cooling down to room temperature, adding a coupling agent and then heating to 120-150°C for surface modification to form wood fibers; Heat and dry the glass fiber, add dispersant and coupling agent to modify the surface at 80-120°C to form glass fiber; clean the thermoplastic, dry it thoroughly, and then granulate it to form thermoplastic;

[0021] Step S2, adding stabilizers, toughening agents, plasticizers and inorganic fillers to wood fibers, glass fibers and thermoplastics and mixing uniformly, wherein: the mixing temperature is 25°C, and the mixing time is 120s;

[0022] Step S3, extruding and granulating to form new recycled wood-plastic materials.

[0023] During specific implementation, step S1 includes the preparation ...

Embodiment 1

[0041] Example 1: 50 parts of thermoplastic (PE), 25 parts of plant fiber, 20 parts of inorganic filler, 1 part of coupling agent, and 2 parts of stabilizer. The resulting wood-plastic material has a bending strength of 35MPa and an impact strength of 16 kJ / m 2 .

Embodiment 2

[0042] Example 2: 50 parts of thermoplastic (PVC), 25 parts of plant fiber, 20 parts of inorganic filler, 1 part of coupling agent, and 2 parts of stabilizer. The bending strength of the wood-plastic material made is 32MPa, and the impact strength is 18kJ / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com