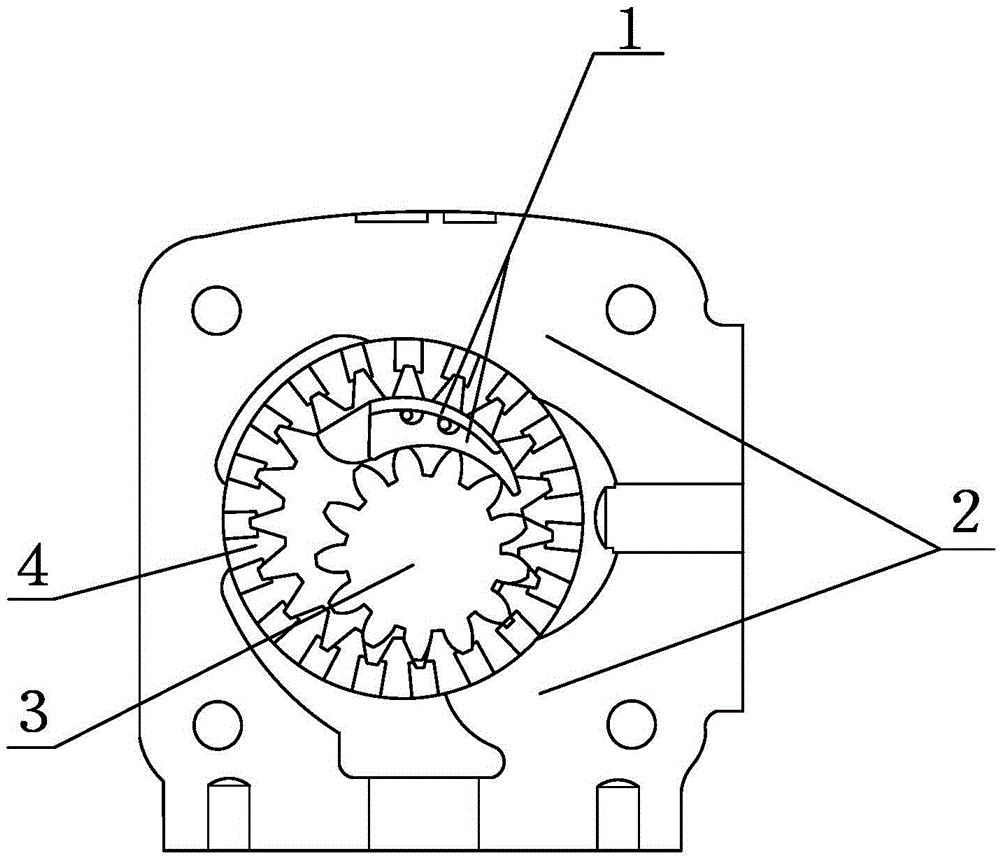

A method for machining an internal gear ring used in an internal gear pump

An internal gear pump and processing method technology, applied in the field of mechanical processing, can solve the problems that the depth of the nitrided layer cannot meet the use requirements, the surface roughness of the inner gear ring cannot be guaranteed, the material consumption and product energy consumption are large, etc. The structure of the nitrided layer is easy to control, the processing procedure is simple, and the effect of improving the precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The following nitrided steel materials are selected as raw materials, sawed according to the shape and specification of the ring gear used in the internal gear pump, and then forged to form a rough ring ring. The nitrided steel material is composed of the following mass percentages: C: 0.38%, Si: 0.30%, Mn: 0.50%, Cr: 1.50%, Al: 0.90%, Mo: 0.22%, Ni: 0.20%, Cu: 0.:25%, S: 0.03:0%, P: 0.035%, and the balance is Fe.

[0025] The inner ring gear blank produced above was subjected to normalizing treatment, the temperature of the normalizing treatment was 940° C., the holding time was 3 hours, and air cooling was performed after the normalizing treatment.

[0026] The above-mentioned air-cooled ring gear blank is subjected to rough turning, quenching and tempering treatment, and then finishing turning, drilling, deburring and annealing treatment. The specific process of the quenching and tempering treatment is to preheat the rough-turned inner ring gear blank first, the pre...

Embodiment 2

[0029]The following nitrided steel materials are selected as raw materials, sawed according to the shape and specification of the ring gear used in the internal gear pump, and then forged to form a rough ring ring. The nitrided steel material is composed of the following mass percentages: C: 0.36%, Si: 0.40%, Mn: 0.4%, Cr: 1.6%, Al: 0.7%, Mo: 0.23%, Ni: 0.25%, Cu: 0.25%, S: 0.030%, P: 0.025%, and the balance is Fe.

[0030] The inner ring gear blank produced above was subjected to normalizing treatment, the temperature of the normalizing treatment was 930° C., the holding time was 3 hours, and air cooling was performed after the normalizing treatment.

[0031] The above-mentioned air-cooled ring gear blank is subjected to rough turning, quenching and tempering treatment, and then finishing turning, drilling, deburring and annealing treatment. The specific process of the quenching and tempering treatment is to preheat the rough-turned inner ring gear blank first, the preheatin...

Embodiment 3

[0034] The following nitrided steel materials are selected as raw materials, sawed according to the shape and specification of the ring gear used in the internal gear pump, and then forged to form a rough ring ring. The nitrided steel material is composed of the following components by mass percentage: C: 0.40%, Si: 0.20%, Mn: 0.60%, Cr: 1.40%, Al: 1.10%, Mo: 0.20%, Ni: 0.30%, Cu: 0.30%, S: 0.025%, P: 0.020%, and the balance is Fe.

[0035] The inner ring gear blank produced above was subjected to normalizing treatment, the temperature of the normalizing treatment was 950° C., the holding time was 4 hours, and air cooling was performed after the normalizing treatment.

[0036] The above-mentioned air-cooled ring gear blank is subjected to rough turning, quenching and tempering treatment, and then finishing turning, drilling, deburring and annealing treatment. The specific process of the quenching and tempering treatment is to preheat the rough-turned inner ring gear blank fir...

PUM

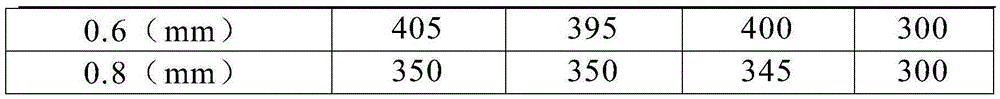

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com