Forming method of tee joint half-tube part and compound punching die

A technology of stamping dies and parts, which is applied to the stamping forming method of special-shaped tee half-pipe parts and composite stamping dies, and the forming field of aluminum alloy plate parts, which can solve the problem of insufficient ductility of materials and poor ductility of aluminum alloy materials , It is impossible to eliminate problems such as wrinkles, and achieve the effect of low operator level dependence, low shape requirements, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Referring to accompanying drawing, concrete steps are implemented as follows:

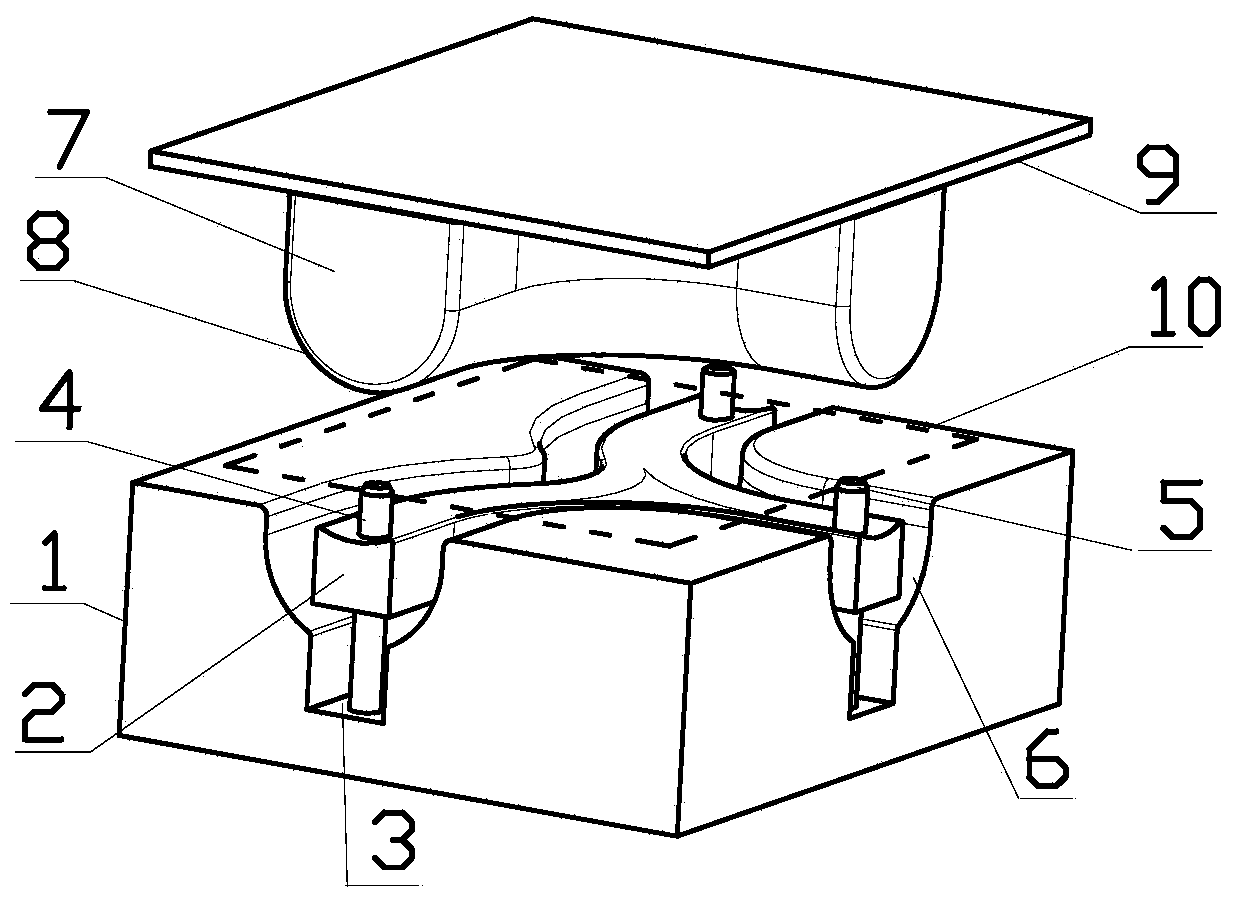

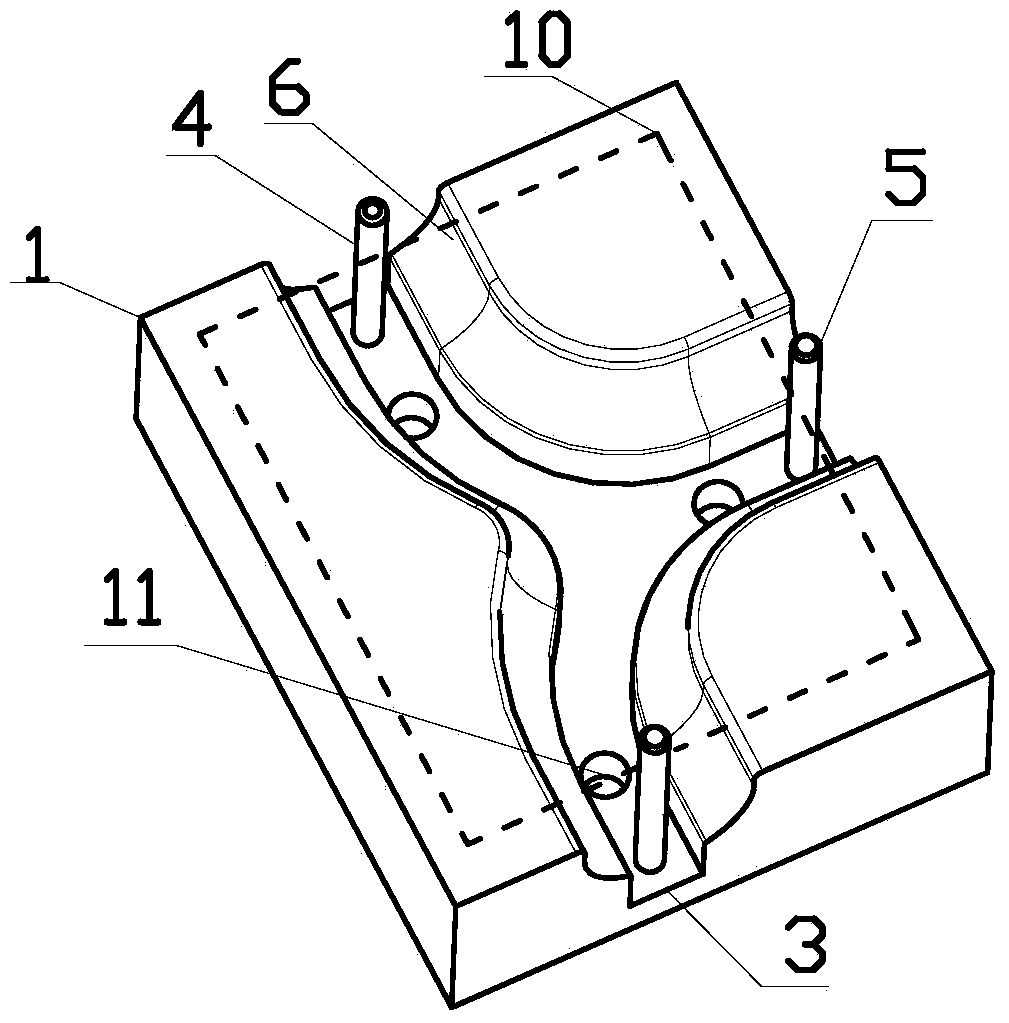

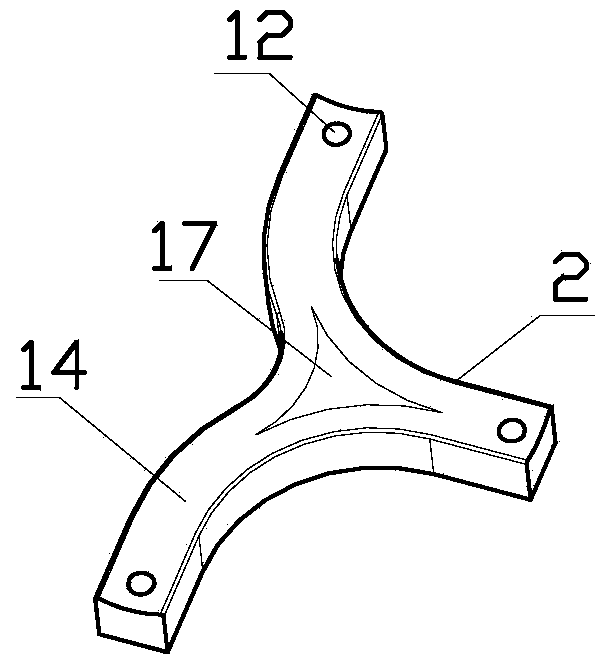

[0018] The composite stamping die for three-way half-pipe parts includes a lower die 1, a compression block 2, and an upper die 7. The body of the lower die 1 is a block structure with parallel upper and lower surfaces, and a depression is provided on the upper surface of the lower die body. The concave surface 6, the concave surface matches the shape of the tee pipe part 16, the bottom of the concave surface 6 is provided with a deeper concave avoidance groove 3, and the bottom of the avoidance groove is provided with a guide column 4 and a top respectively near the notch end. The rod through hole 11, the guide column 4 is vertically upward and the upper end is similar to a conical chamfer 5, the ejector rod through hole 11 is perpendicular to the bottom of the avoidance groove 3 and corresponds to the position of the ejector rod of the machine tool; the shape of the pressing block 2 is cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com