Preparation method of oxidized graphene phase change microcapsule

A phase change microcapsule, graphene technology, applied in the directions of microcapsule preparation, microsphere preparation, chemical instruments and methods, etc., to achieve the effect of improving heat transfer performance, excellent thermal conductivity, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation of Graphene Oxide Cetyl Alcohol Microcapsules

[0042] (1) Preparation of graphene oxide solution.

[0043] Weigh 0.25g of 50um graphite oxide, add 500ml of deionized water, stir for 30min, and sonicate for 3h to prepare a 0.05mg / l graphene oxide solution.

[0044] (2) Preparation of emulsion.

[0045] Weigh 1 g of cetyl alcohol, and add 10 ml of a 0.05 mg / 1 graphene oxide solution. Heating at 80°C, cetyl alcohol melted, stirring for 60min at a stirring speed of 400r / min, and a stable Pickering emulsion was obtained.

[0046] (3) Preparation of microcapsules.

[0047] Add H dropwise to the emulsion 2 SO 4 , Reaction 2h. When the pH value of the system is 2-3, the graphene oxide will condense, and the graphene oxide will completely cover the phase change material emulsion droplets through the force, and will form capsules and precipitate out after cooling.

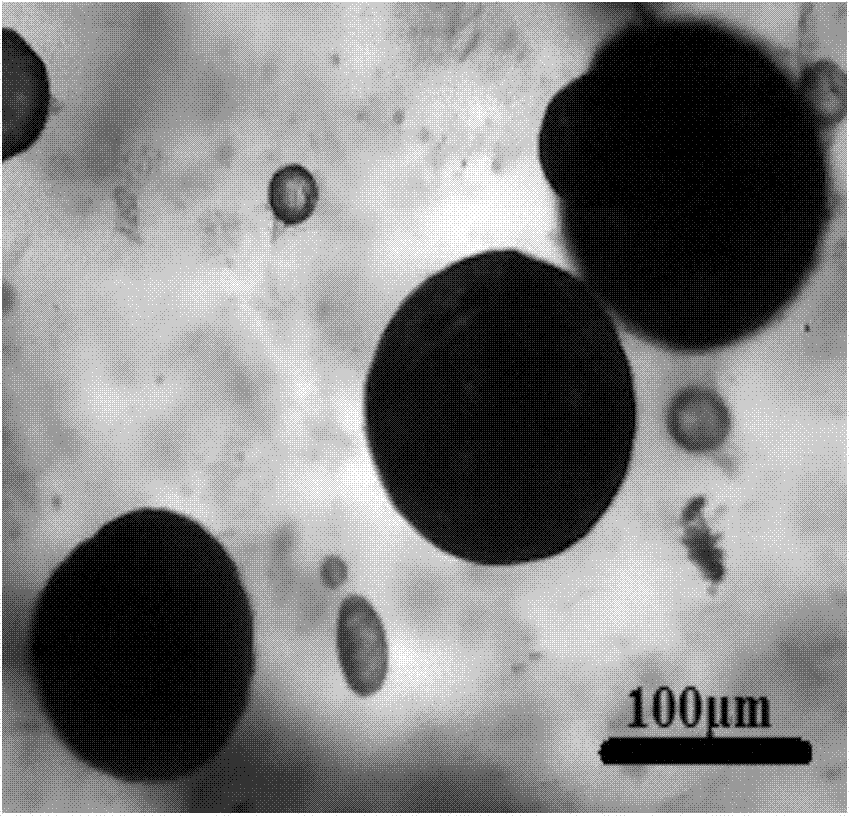

[0048] The microscope picture of the graphene oxide phase-change capsule prepared by the presen...

Embodiment 2

[0050] Preparation of Graphene Oxide Cetyl Alcohol Microcapsules

[0051] (1) Preparation of graphene oxide solution.

[0052] Weigh 0.5g of 50um graphite oxide, add 500ml of deionized water, stir for 30min, and sonicate for 3h to prepare a 1mg / ml graphene oxide solution.

[0053] (2) Preparation of emulsion.

[0054] Weigh 1 g of cetyl alcohol and add 10 ml of 1 mg / ml graphene oxide solution. Heating at 80°C, cetyl alcohol melted, stirring for 60min at a stirring speed of 400r / min, and a stable Pickering emulsion was obtained.

[0055] (3) Preparation of microcapsules.

[0056] Add H dropwise to the emulsion 2 SO 4 , Reaction 2h. The pH value of the system is 2-3, the graphene oxide is condensed, and the graphene oxide completely covers the emulsion droplet of the phase change material through the force, and is cooled into capsules and precipitated to obtain graphene oxide cetyl alcohol microcapsules.

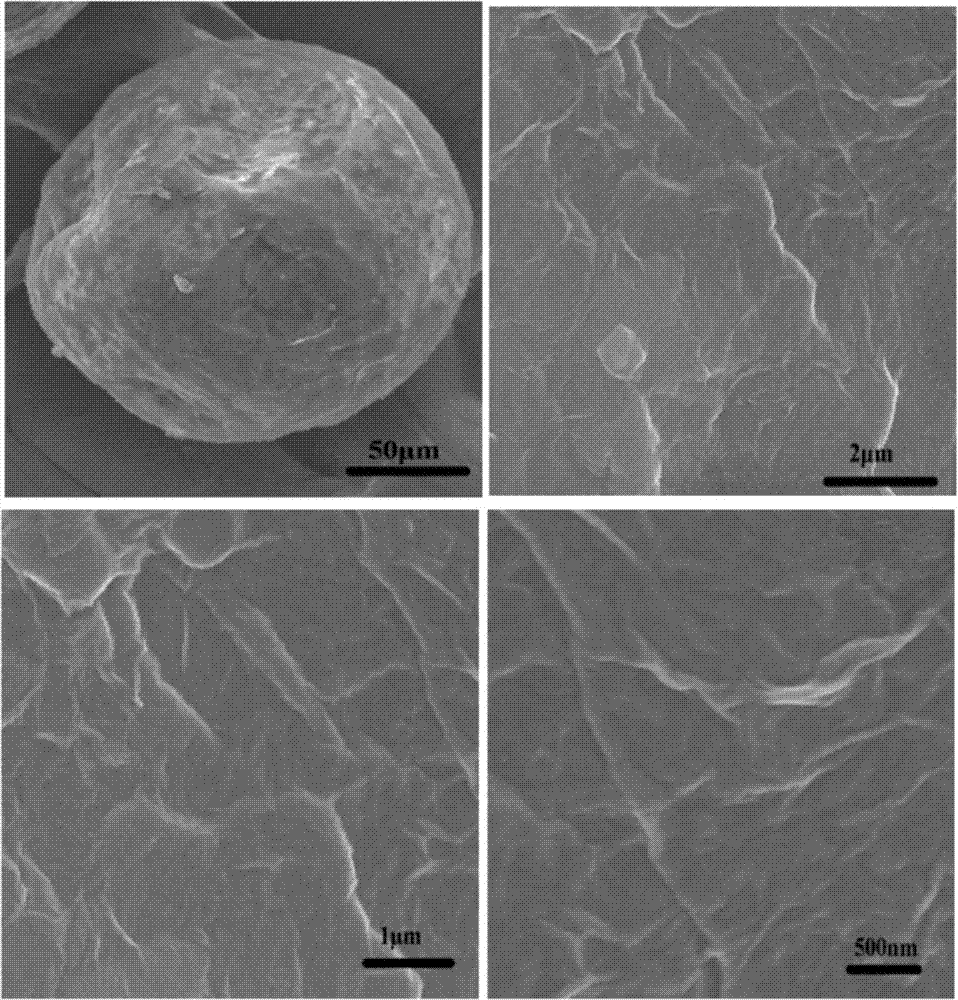

[0057] The microscope picture of the graphene oxide phase-change c...

Embodiment 3

[0059] Preparation of Graphene Oxide Cetyl Alcohol Microcapsules

[0060] (1) Preparation of graphene oxide solution.

[0061] Weigh 1g of 50um graphite oxide, add 500ml of deionized water, stir for 30min, and sonicate for 3h to prepare a 2mg / ml graphene oxide solution.

[0062] (2) Preparation of emulsion.

[0063] Weigh 1 g of cetyl alcohol and add 10 ml of 2 mg / ml graphene oxide solution. Heating at 80°C, cetyl alcohol melts, stirring for 1 hour at a stirring rate of 400r / min, and a stable Pickering emulsion is obtained.

[0064] (3) Preparation of microcapsules.

[0065] 1ml of H was added dropwise to the emulsion 2 SO 4 , Reaction 2h. The pH value of the system is 2-3, the graphene oxide is condensed, and the graphene oxide completely covers the emulsion droplet of the phase change material through the force, and is cooled into capsules and precipitated to obtain graphene oxide cetyl alcohol microcapsules.

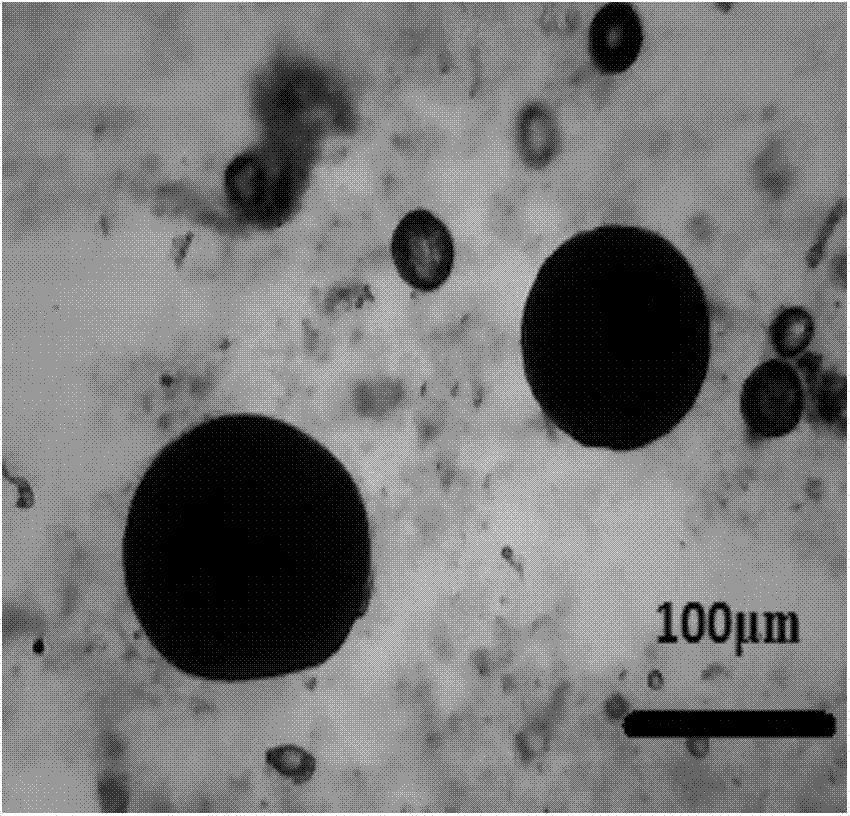

[0066] The microscope image of the graphene oxide phase-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com