Waterproof breathable cotton cloth

A waterproof and breathable cotton cloth technology, applied in the field of fabrics, can solve the problems of cotton cloth that is not easy to drain moisture, uncomfortable, easy to absorb water, etc., and achieve good waterproof and breathable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] A waterproof breathable cotton cloth, comprising a waterproof layer and a cotton cloth layer, the thickness of the waterproof layer is 0.03mm, and the thickness of the cotton cloth layer is 0.15mm.

[0013] The waterproof layer is made of the following raw materials in parts by weight: 25 parts of polyvinyl alcohol, 30 parts of p-toluenesulfonic acid, 50 parts of sodium o-hydroxybenzoate, 30 parts of silicon dioxide, 20 parts of anhydrous sorbic acid stearate, surface Active agent sodium dodecylbenzenesulfonate 25 parts.

[0014] Preparation of the waterproof layer: Mix all the raw materials evenly.

Embodiment 2

[0016] A waterproof breathable cotton cloth, comprising a waterproof layer and a cotton cloth layer, the thickness of the waterproof layer is 0.02mm, and the thickness of the cotton cloth layer is 0.1mm.

[0017] The waterproof layer is made of the following raw materials in parts by weight: 20 parts of polyvinyl alcohol, 20 parts of p-toluenesulfonic acid, 40 parts of sodium o-hydroxybenzoate, 20 parts of silicon dioxide, 10 parts of anhydrous sorbic acid stearate, surface Active agent stearic acid 20 parts.

[0018] Preparation of the waterproof layer: Mix all the raw materials evenly.

Embodiment 3

[0020] A waterproof breathable cotton cloth, comprising a waterproof layer and a cotton cloth layer, the thickness of the waterproof layer is 0.04mm, and the thickness of the cotton cloth layer is 0.2mm.

[0021] The waterproof layer is made of the following raw materials in parts by weight: 30 parts of polyvinyl alcohol, 40 parts of p-toluenesulfonic acid, 60 parts of sodium o-hydroxybenzoate, 40 parts of silicon dioxide, 30 parts of anhydrous sorbic acid stearate, surface Active agent sodium dodecylbenzenesulfonate 30 parts.

[0022] Preparation of the waterproof layer: Mix all the raw materials evenly.

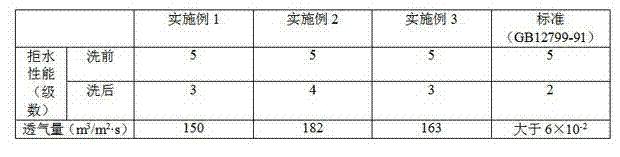

[0023] Performance parameter of the present invention:

[0024]

[0025] It can be seen from the above that the water repellency of the present invention is still greater than 2 after washing, and the air permeability is 150-182m 3 / m 2 s, indicating that the present invention has good waterproof and breathable performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com