A radial permanent magnet drive motor for an electric van transport vehicle

A technology of permanent magnet drive and vehicle diameter, applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve power, torque drop, DC motor Problems such as high energy consumption and reduced motor efficiency achieve the effects of less power consumption, improved product quality, and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

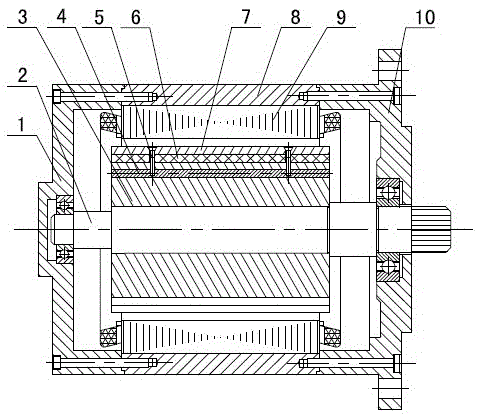

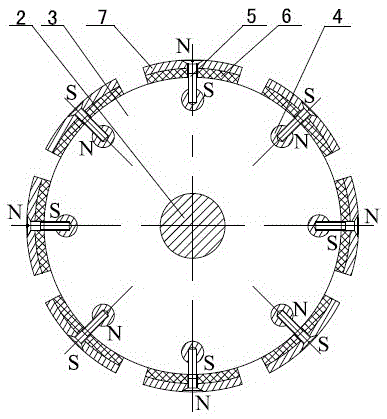

[0018] Figure 1~2 It is the best embodiment of the present invention. Figure 1~2 The present invention will be further explained.

[0019] Reference attached figure 1 : The radial permanent magnet drive motor of this electric van includes a rear end cover 1, a shaft 2, a rotor, a casing 8, a stator 9 and a front end cover 10. The outer ring of the rotor is fixed with a stator 9 and both the rotor and the stator 9 are fixed. It is installed in the space formed by the front cover 10, the rear cover 1 and the cabinet 8. The shaft 2 passes through the center of the rotor. Both ends of the shaft 2 are supported and mounted on the rear end cover 1 and the front end cover 10 through bearings, and one end of the shaft 2 protrudes from the front end cover 10.

[0020] Attached figure 1 And figure 2 It can be seen that: in this embodiment, the rotor adopts a radial permanent magnet rotor with pole shoes 7, and the main components include the rotor core 3, iron rivets 4, screws 5, tile p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com