Production technology of LED nixie tube connecting board

A production process and digital tube technology, applied in the direction of instruments, electrical components, circuits, etc., can solve the problems of low efficiency and high defect rate, and achieve the effect of flexible and simplified operation, improved production efficiency, and optimized process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

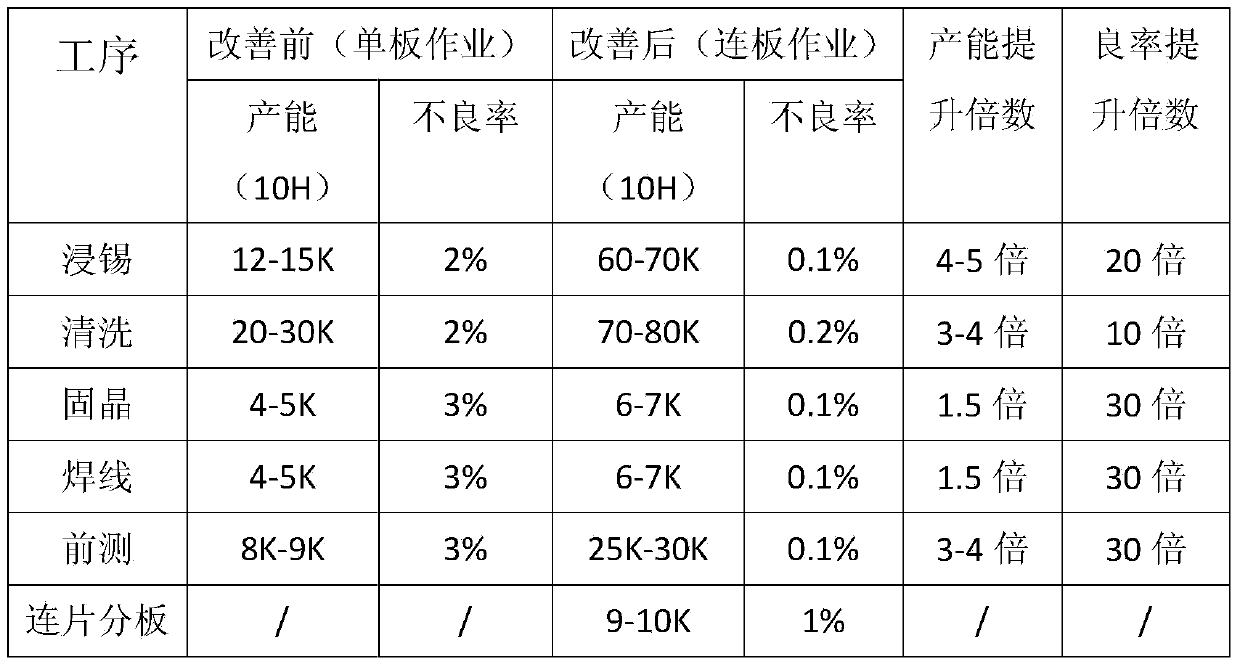

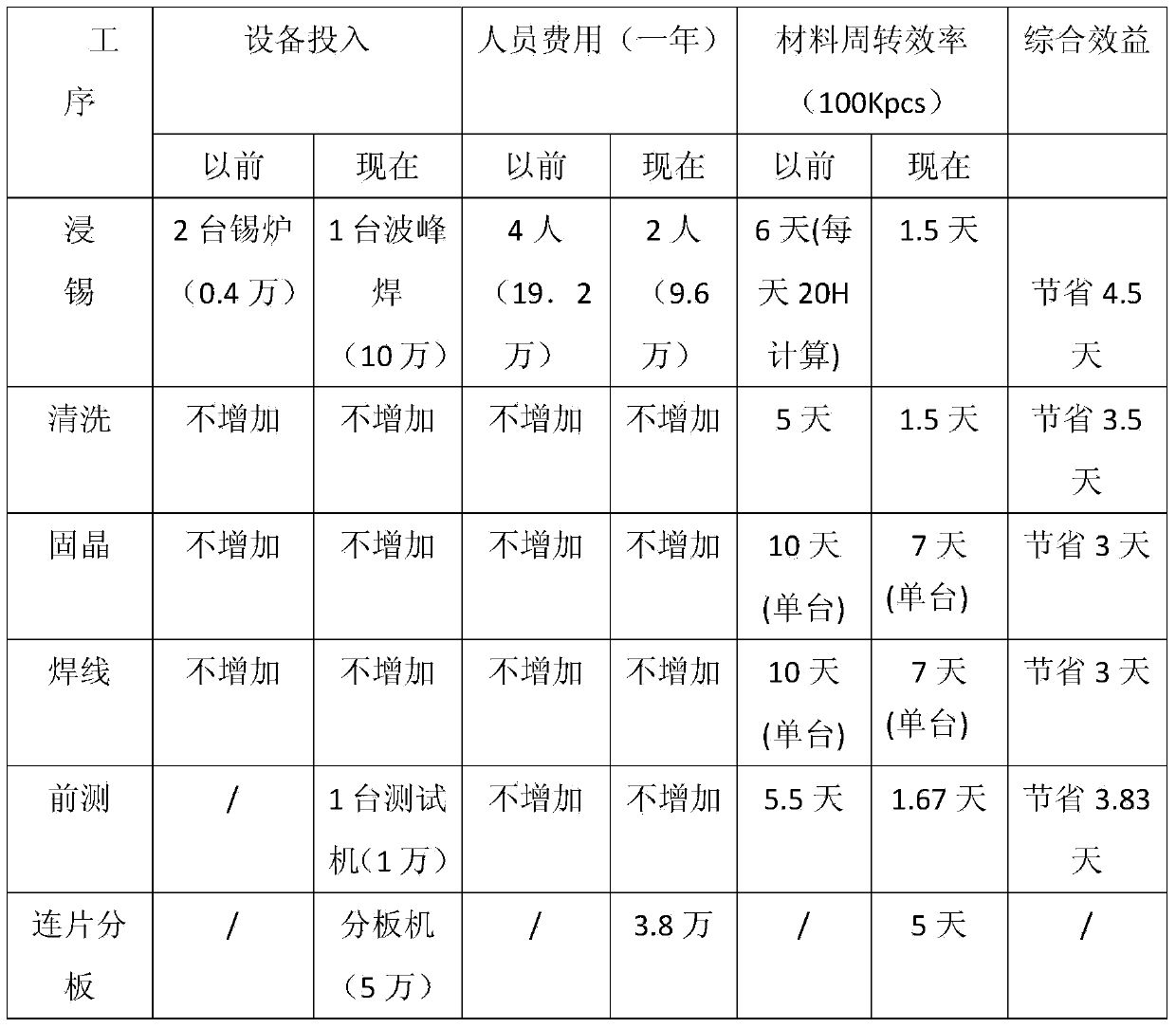

[0011] The process of the present invention, from jumping PIN→pressing PIN→dipping tin→cleaning→solid crystal→wire bonding→testing, all adopts connecting board operation, on the one hand, the production efficiency of each process is improved, on the other hand, the PIN pin is deformed and the chip is erased , Collapsed aluminum wire and other bad problems have been effectively improved.

[0012] LED nixie tube connecting board production process is characterized in that described production process comprises the following steps:

[0013] A. Preliminary steps: After jumping PIN and pressing PIN on the connected PCB board, directly install the connected PCB board on the dipping tin fixture, and automatically dip tin with wave soldering. After dipping the connected PCB board, there is no need to divide the board, Use the cleaning basket to move it into the ultrasonic cleaning equipment for cleaning, and then bake it after cleaning; PIN jumping on the whole board is convenient and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com