Thermal insulation lifting head used for connecting with suspender type air pipe and assembling method of thermal insulation lifting head

An assembly method and a technology of heat insulation components, which are applied in the direction of protecting pipes, pipes/pipe joints/pipes, pipe supports, etc. through heat insulation, can solve the problems of high cost, poor fire resistance, and many potential safety hazards, so as to avoid waste, The effect of ensuring thermal insulation performance and reducing safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

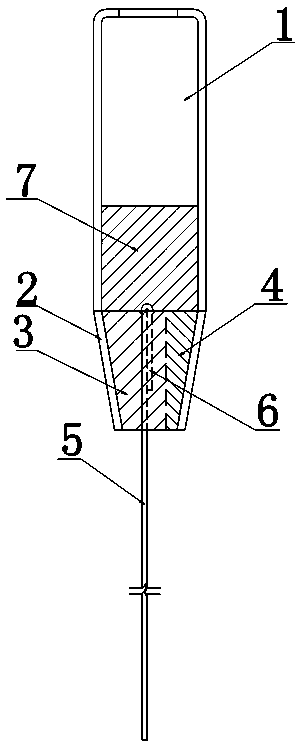

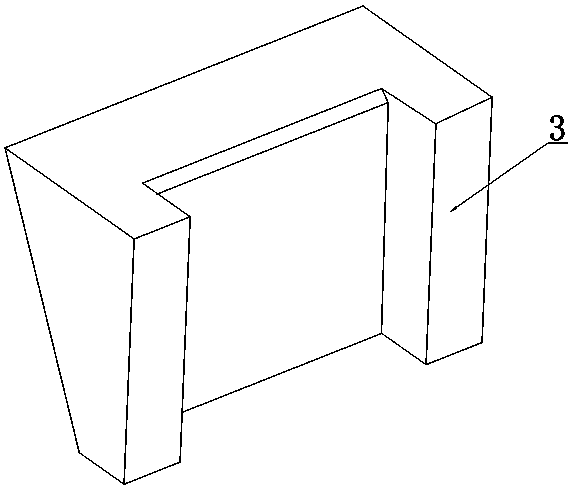

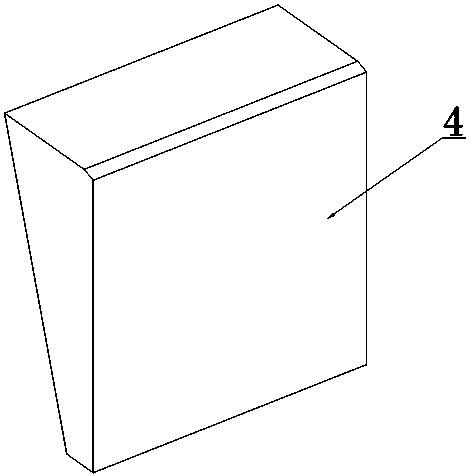

[0039] Such as Figure 1~5 As shown, the present invention is mainly used as a connector for installing a sling-type air duct, which includes an adjustment frame 1 , a locking load-bearing mechanism and a sling 5 . The adjustment frame 1 is used to adjust the installation elevation of the air duct, and an adjustment cavity is provided inside it. One end of the sling 5 is connected to the air duct, and the other end is provided with a bending portion 6 , the sling 5 plays a role of connecting the air duct and the adjustment frame 1 . The locking load-bearing mechanism is used to lock the sling 5 to prevent the air duct from falling off, so as to realize the hoisting of the air duct. The heat insulation assembly embedded in the clamping frame 2 is preferred to ensure the locking and load-bearing effect of the locking load-bearing mechanism. The clamping frame 2 in this embodiment is in the shape of a hopper, and the outside of the heat insulation assembly is close to the card. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com